Novel movable jaw integrated crushing station

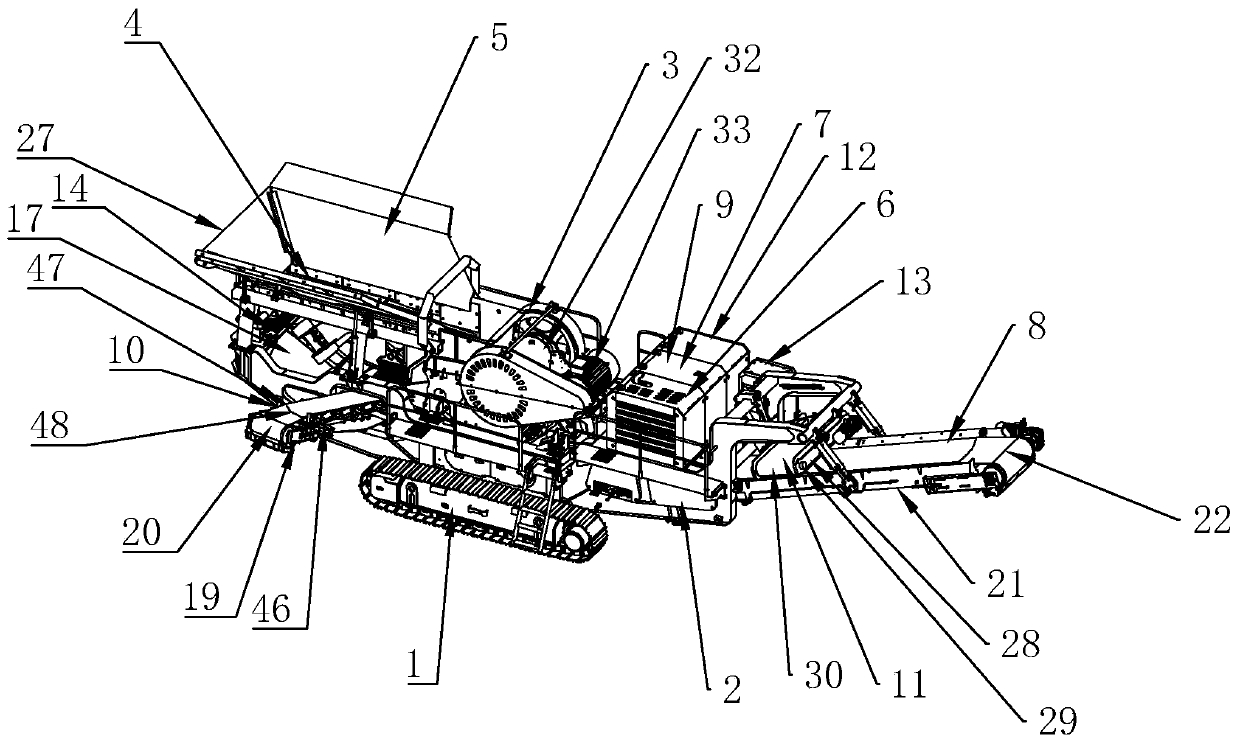

A crushing station and jaw-type technology, applied in the field of new mobile jaw-type integrated crushing station, can solve the problems of low degree of automation and unstable control performance, and achieve the effect of high degree of intelligence and coordinated actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As an improved specific embodiment, the second conveying assembly includes several second roller sets, and several second roller sets are installed on the second installation frame 19, and several second roller sets are divided into left rollers The middle sides of the wheel set unit 46 and the right roller set unit 47 , the left roll set unit 46 and the right roll set unit 47 are inclined downward to form a concave receiving surface 48 .

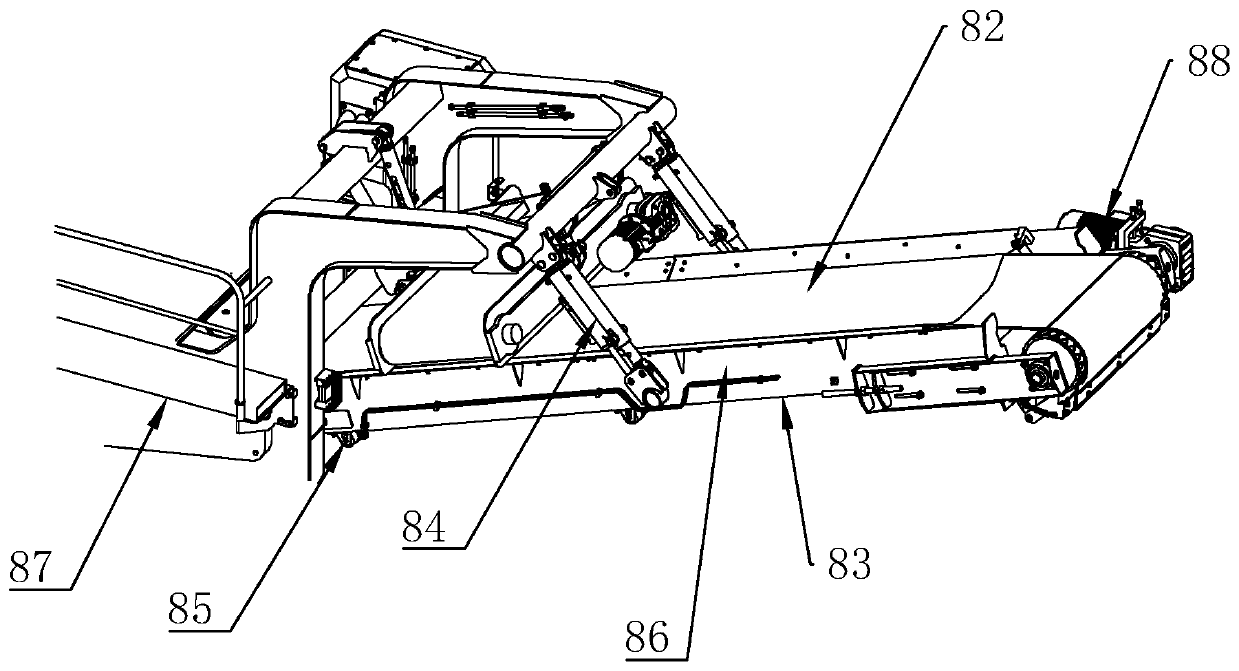

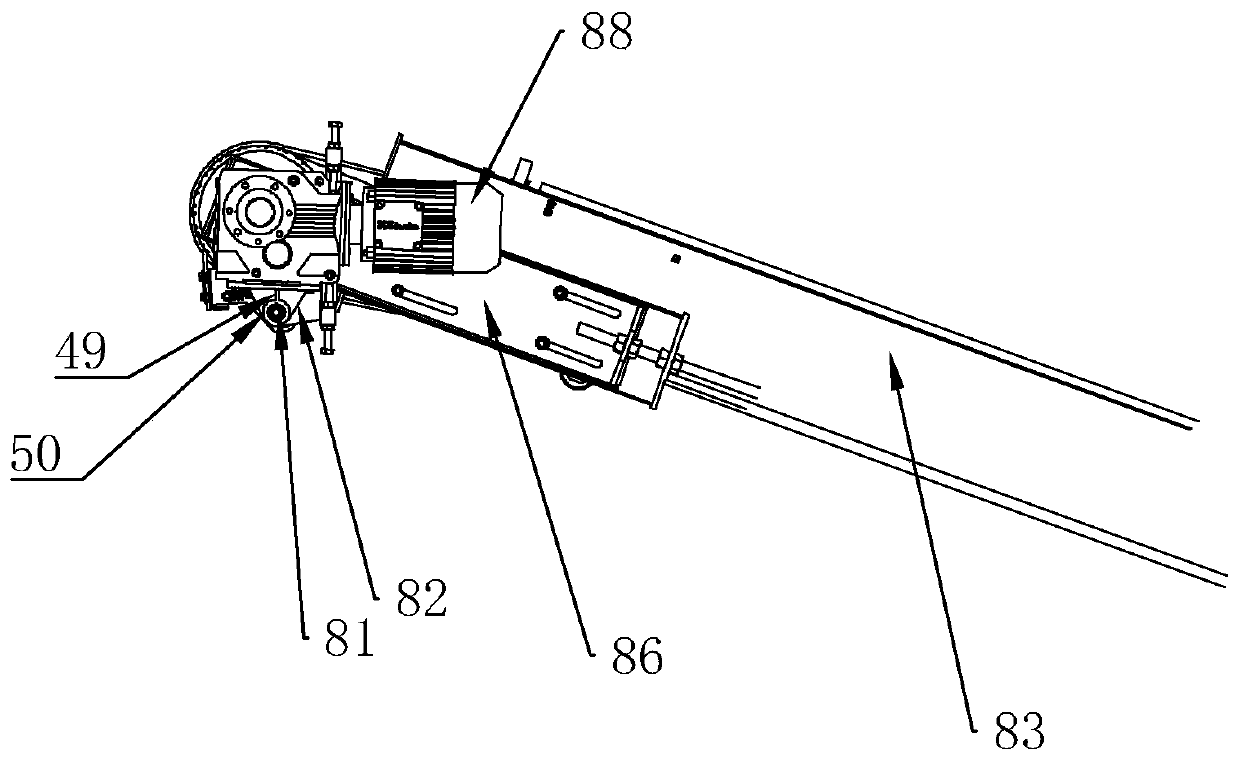

[0052] As an improved specific embodiment, the belt-type main conveyor 8 is composed of an adjustment cylinder 33, a conveyor belt 82, a frame 83 at the front of the conveyor, a hydraulic adjustment positioning rod 84, a hinged device 85, a fixed plate 86, The rear section frame 87 of the feeder is composed of a main feeding motor 88, and the rear section frame 87 of the feeder is fixedly connected to the rear end of the vehicle frame 2, and the front section frame 83 of the feeder is connected through a hinged device 85 It is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com