Simple-structure sizing die for optical cable or power cable

A technology for sizing molds and cables, which is applied in the field of cables, can solve the problems of long time for mold replacement, inconvenient use, waste of resources, etc., and achieve the effects of saving personnel and time costs, avoiding wrong mold selection, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

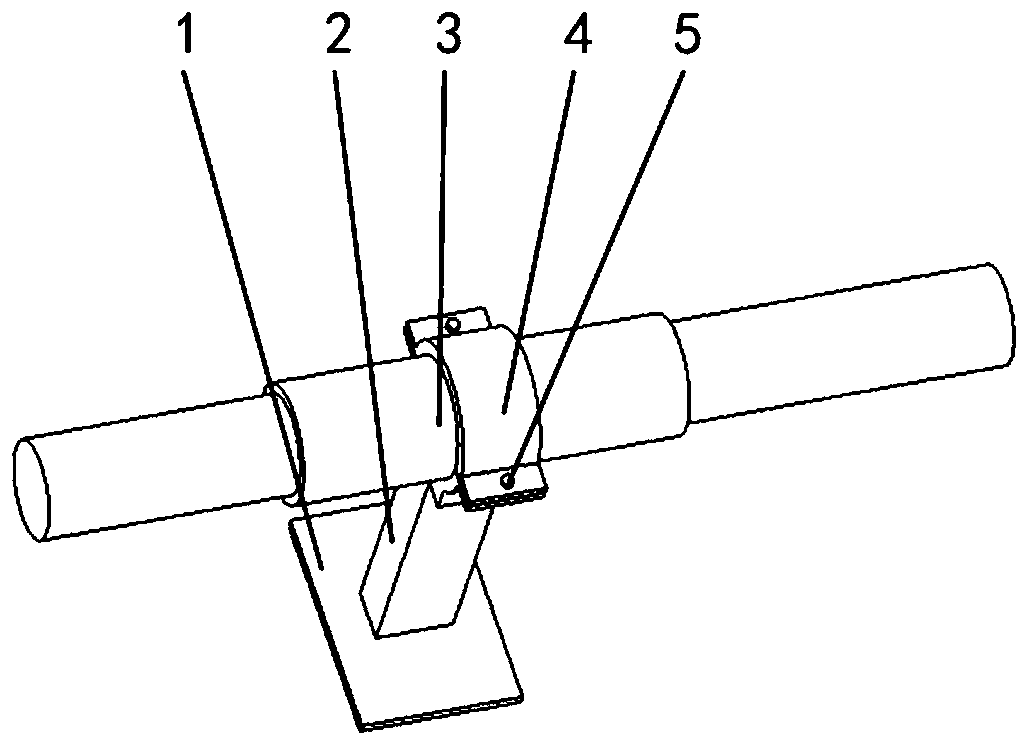

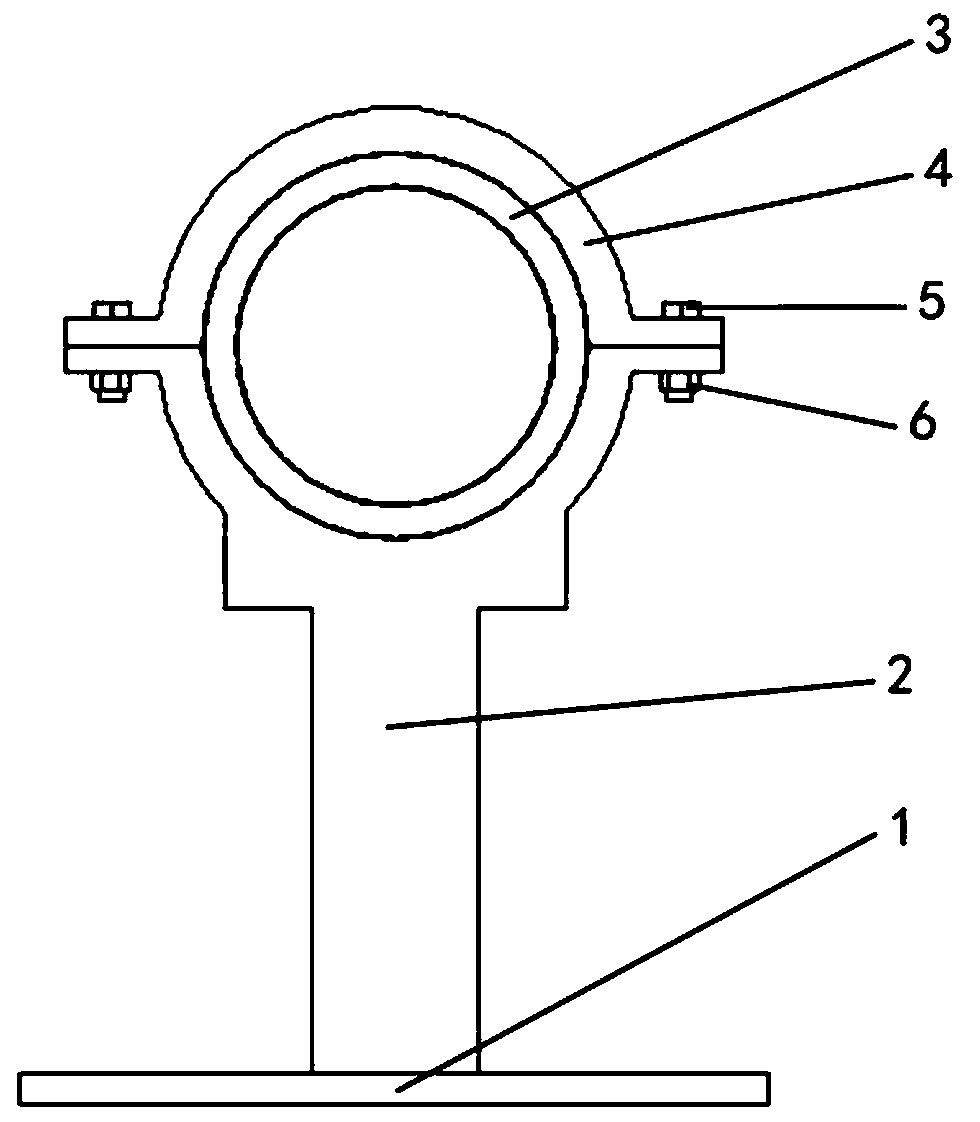

[0027] please see figure 1 , Figure 8 , Figure 9 with Figure 10 , a sizing mold with a simple structure for optical cables or cables, has a base 1, a support unit 2, a mold body 3 and a fixing member 4, and is characterized in that the support unit 2 is composed of a support unit body 22, and the upper end of the support unit body 22 is formed The support unit notch 21 forms a plurality of first fixing holes 23 on the left and right sides, the mold main body 3 is located in the support unit notch 21, and the support unit 2 is also provided with a fixing member 4, and the fixing member 4 is formed by the fixing member main body 41 Composition, below the main body 41 of the fixing member is also provided with a fixing member notch 42, and a plurality of second fixing holes 43 are formed on the left and right sides, and the bolt 5 passes through the first fixing hole 23, the corresponding second fixing hole 43 and connects with the nut. 6, the fixing member 4 and the suppor...

Embodiment 2

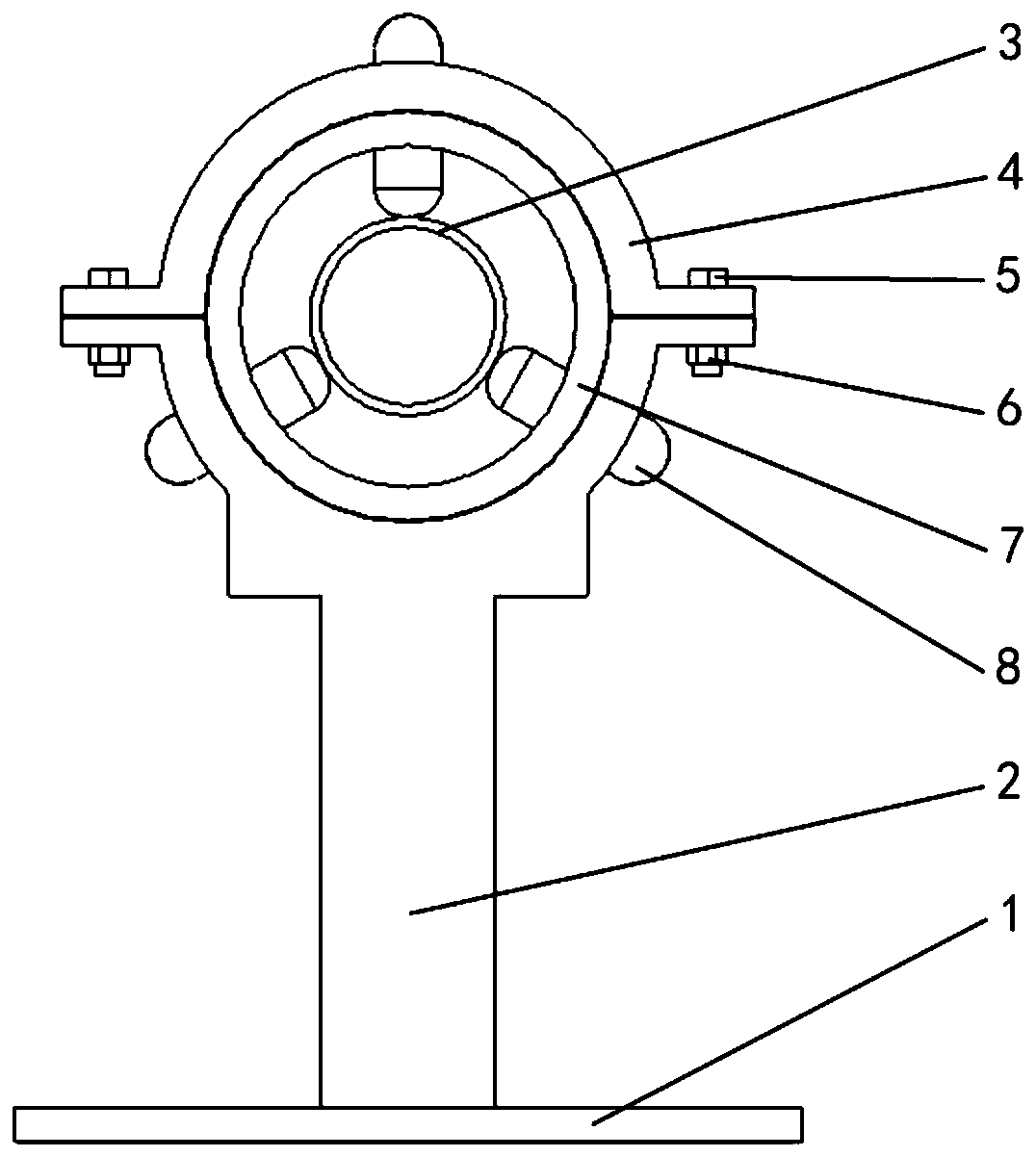

[0029] please see image 3 , Figure 5 , Image 6 , Figure 8 , Figure 9 with Figure 10 , a simple structure sizing mold for optical cable or cable, has a base 1, a support unit 2, a mold body 3, a fixing member 4, a rotating rod 8 and a positioning frame 7; it is characterized in that the support unit 2 consists of a support unit body 22 The upper end of the support unit main body 22 forms a support unit notch 21, a plurality of first fixing holes 23 are formed on the left and right sides, the positioning frame 7 is located in the support unit notch 21, the mold main body 3 is located in the positioning frame 7, and the positioning frame 7 is made of locating frame main body 71, and positioning chamber 73 is formed in the middle, and three threaded holes 72 are formed in the same plane of locating frame main body 71, and each threaded hole 72 has a rotating rod 8 respectively, and described rotating rod is formed by rotating rod The main body 81, the thread 82 position...

Embodiment 3

[0031] please see Figure 4 , Figure 5 , Figure 7 , Figure 8 , Figure 9 with Figure 10, a simple structure sizing mold for optical cable or cable, has a base 1, a support unit 2, a mold body 3, a fixing member 4, a rotating rod 8 and a positioning frame 7; it is characterized in that the support unit 2 consists of a support unit body 22 The upper end of the support unit main body 22 forms a support unit notch 21, a plurality of first fixing holes 23 are formed on the left and right sides, the positioning frame 7 is located in the support unit notch 21, the mold main body 3 is located in the positioning frame 7, and the mold main body 3 is curled, and one end of the mold main body 3 is in contact with the inner wall of the mold main body 3 but does not adhere to form the inner cavity of the mold main body 3. The positioning frame 7 is composed of a positioning frame main body 71, and a positioning cavity 73 is formed in the middle. The body is also provided with a mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com