Steel structure assembly system and construction method for prefabricated buildings

A construction method and technology of steel structure, applied in building components, building structure, processing of building materials, etc., can solve problems such as harmful stress, achieve the effect of reliable combination, avoid fatigue damage, and excellent seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

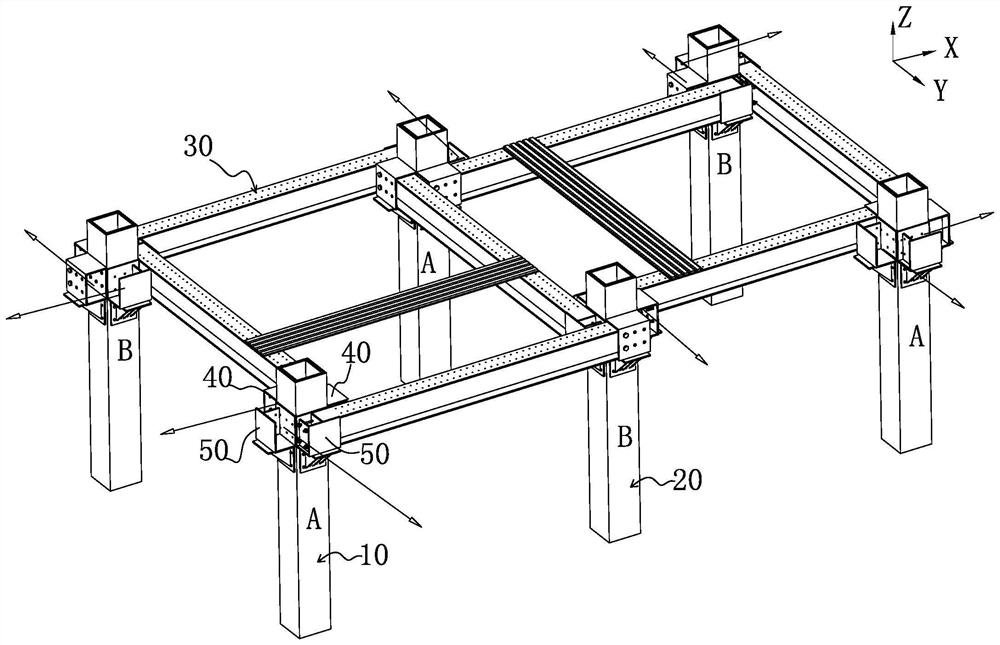

[0064] The first embodiment is implemented for conventional steel structure buildings such as buildings / large public buildings.

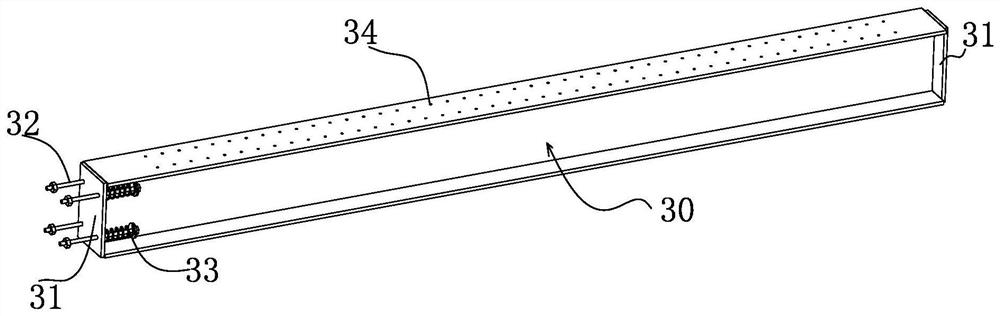

[0065] Steel structure connection system for prefabricated buildings. In steel structure buildings, the steel structure system includes columns, beams and floor structures. The style of the columns usually includes steel pipes with a rectangular section, or an I-shaped section. steel, or other special structures. In this embodiment, a steel pipe with a rectangular section is taken as an example for illustration.

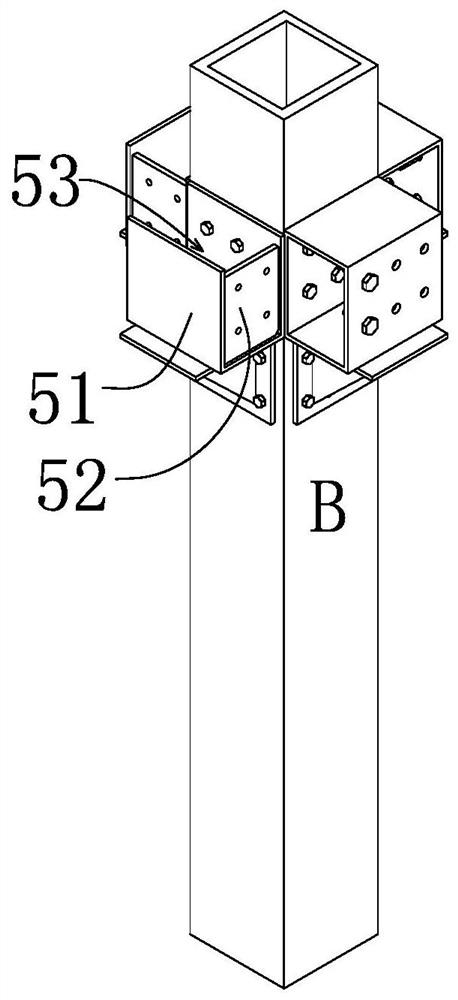

[0066] refer to Figure 1 to Figure 5 , in this embodiment, in the process of building the steel structure, the structure of the column is the same or similar, and according to the angle, method and layout of the supporting components on the column, the column is carried out according to the way of the A column and the B column respectively mark, but it should be noted that there is no essential difference in specifications and sizes bet...

Embodiment 2

[0106] In the first embodiment, four corbels are installed around each column, so that a grid-shaped crossbeam component system is formed in the steel structure system. In the actual steel structure, it can be simplified as required, for example, in each column Two corbels are formed to form a sun-shaped beam assembly system in the steel structure, refer to Figure 13 .

[0107] In this way, two corbels are formed on each column, which can reduce the number of corbels by half and the number of beams by half. This method also meets the following requirements:

[0108] 1. In the same row (X direction), the two adjacent columns A and B have one and only one pair of A corbels and B corbels arranged on the same line with each other, and a beam can be installed between the two corbels hoisting and installation requirements.

[0109] 2. In the same row, there is only one beam connection between two adjacent A columns and B columns;

[0110] 3. Two beams radially arranged in opposi...

Embodiment 3

[0114] Compared with Embodiment 1, this embodiment is different from the B corbel. Specifically, there is no baffle plate in the B corbel, that is to say, the beam and the B corbel are connected by lap joints, and after they are assembled in place, Welding is performed between the beam and the B corbel, so that one end of the beam is welded and fixed to the B corbel, and the other end is slidably connected to the rectangular sleeve in the A corbel. This structure is more convenient to implement than the first embodiment , this implementation structure can refer to Figure 14 with 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com