A steel truss arch support and its construction method

A technology of steel truss and installation part, which is applied in the field of steel truss arch support and its construction, which can solve the problems of difficulty in ensuring the stability of steel truss arch, increase of manpower and mechanical equipment, and single support fixing method, so as to reduce the number of machinery and personnel The effect of consumption, reduction of construction period, and shortening of slippage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now, the structure and principle of the present invention will be fully described in conjunction with specific embodiments, so that those skilled in the art can fully understand and implement it.

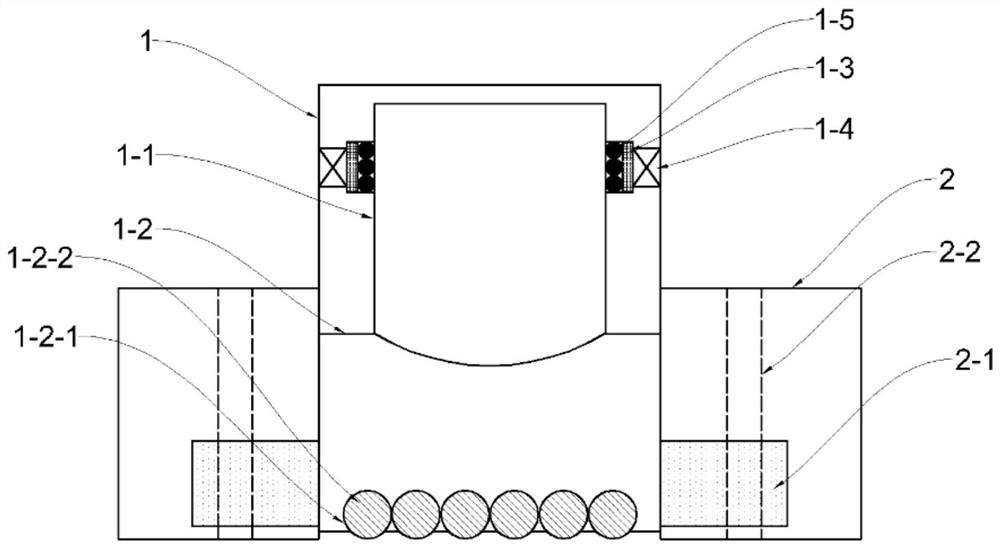

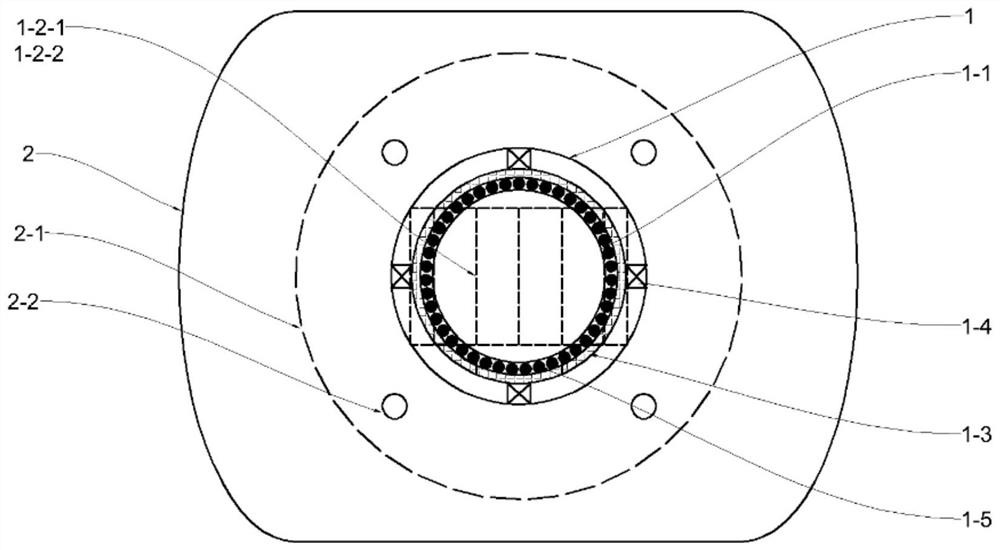

[0025] Such as Figure 1-Figure 2 As shown, a steel truss arch support according to the present invention includes a connecting part 1 and a mounting part 2; the connecting part 1 is cylindrical, and the mounting part 2 is fixedly sleeved on the outside of the connecting part 1; the connecting part 1 is provided with a connecting plate 1-1, and the connecting plate 1-1 is rotated and connected with a sliding plate 1-2, and the sliding plate 1-2 is fixedly connected with the connecting part 1, and the connecting plate 1-1 is columnar The periphery is sleeved on the inner side of the positioning steel ring 1-3 through the positioning ball 1-5 and the cage, and the outer side of the positioning steel ring 1-3 is fixedly connected with the inner wall of the connecting part 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com