Harmonic transmission speed reducing mechanism

A technology of reduction mechanism and harmonic transmission, which is applied in the direction of transmission, transmission parts, mechanical equipment, etc., can solve the problems affecting the stability and accuracy of the harmonic reducer, the large size of the harmonic reducer, and the impact on the service life. Achieve the effects of improving the stability and accuracy of use, compacting the harmonic reducer, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better illustrate and elaborate the content of the present invention, the following will be expanded and described in conjunction with schematic diagrams and implementation examples:

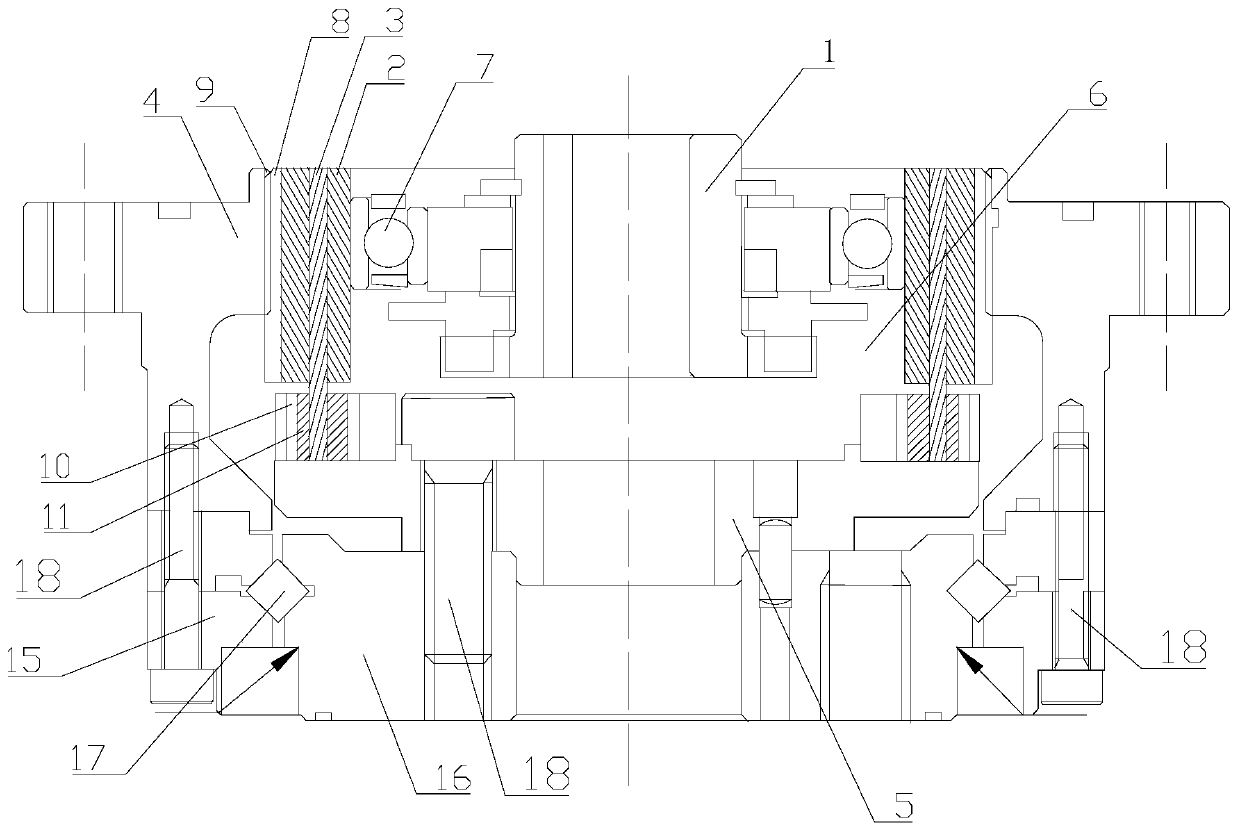

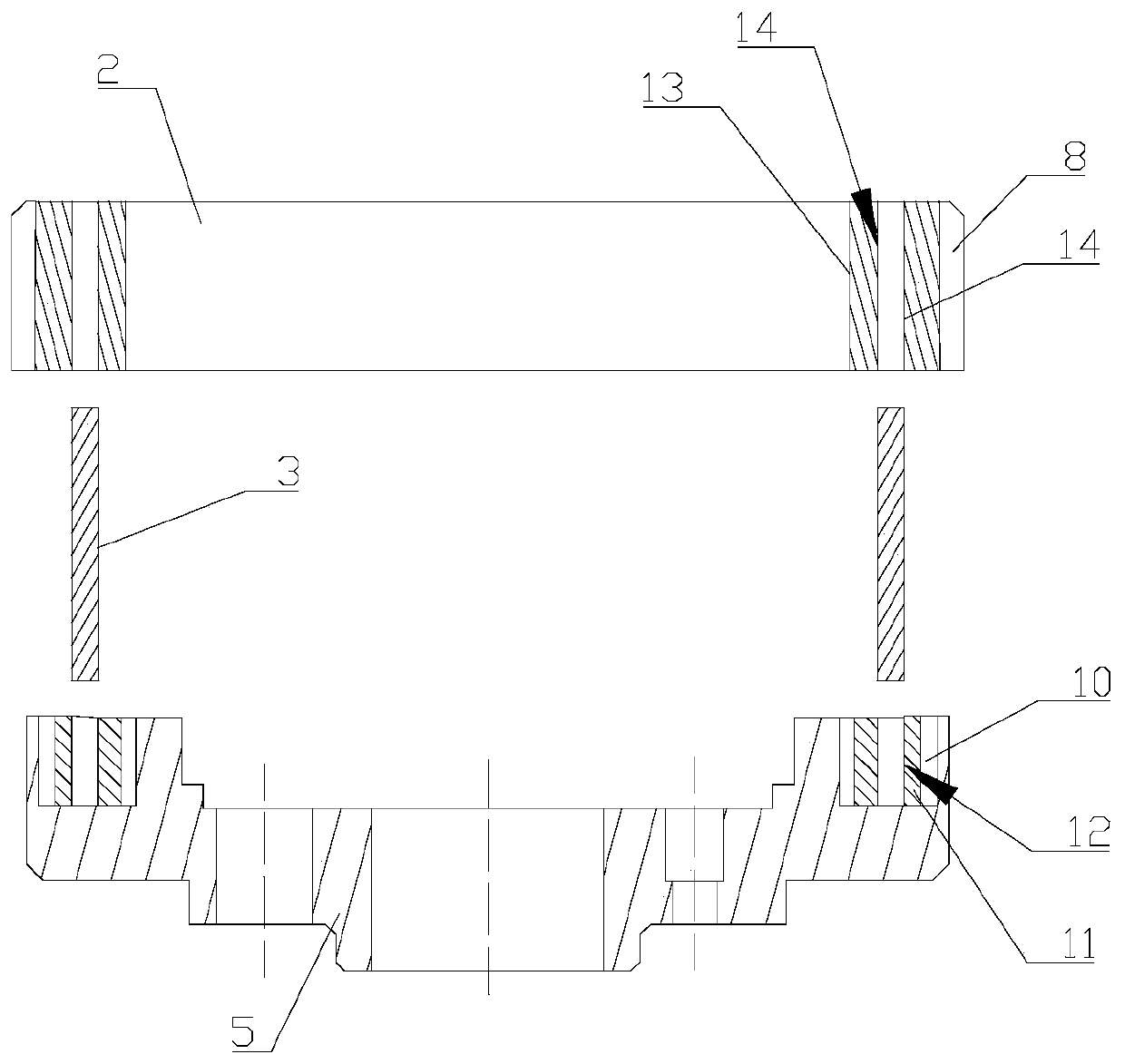

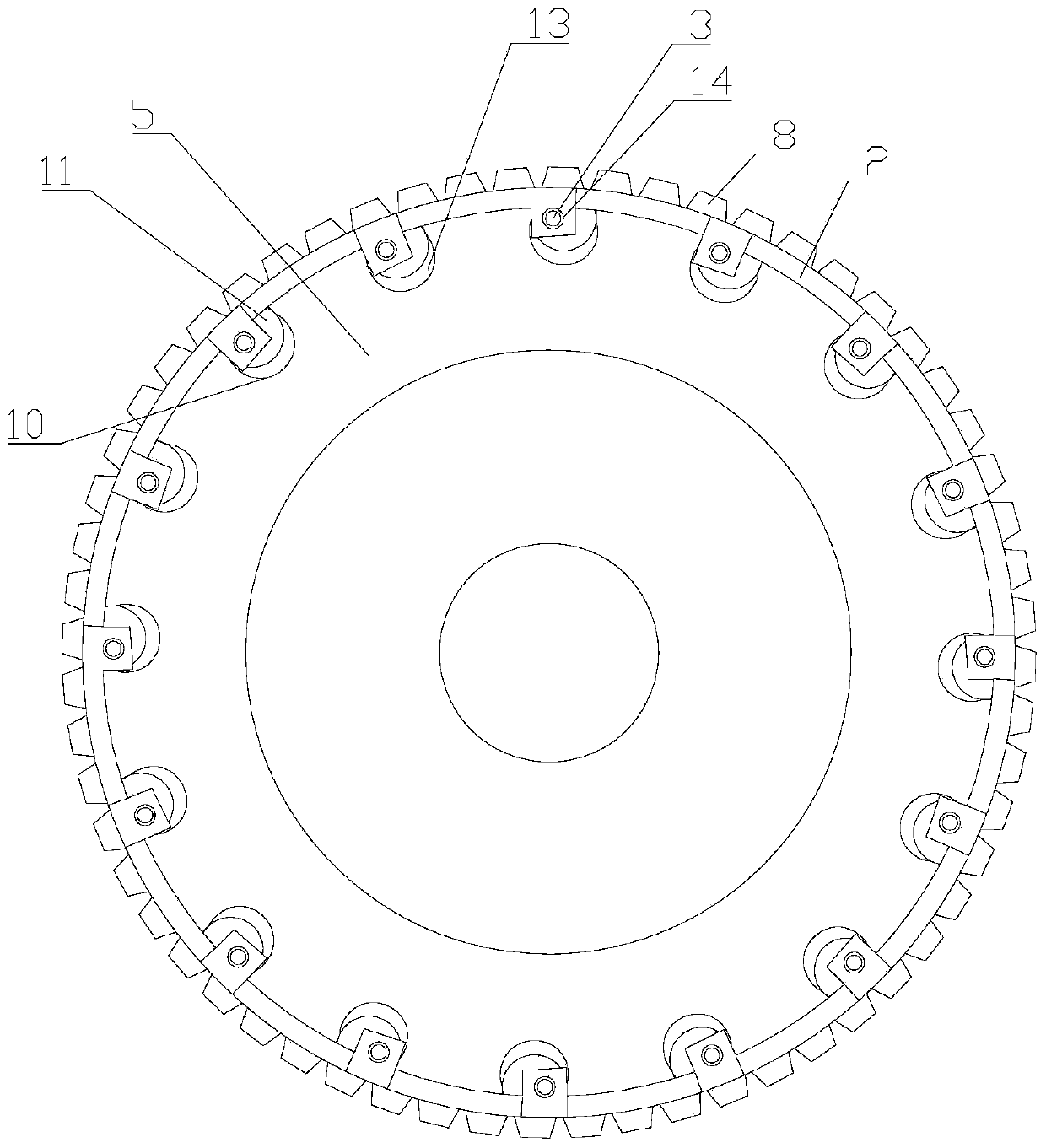

[0021] Depend on Figure 1-Figure 4 , the present invention provides a harmonic transmission reduction mechanism, including a wave generator, a flexible gear 2, a connecting pin 3, a rigid gear 4, a connecting ring 15, and an output plate 5; The accommodation space 6 for accommodating the wave generator 1 and the flexible gear 2, the top end surface of the connecting ring 15 and the bottom end of the rigid gear 4 are connected and fixed by bolts 18; the wave generator includes a cam 1 and a cam bearing 7 sleeved outside the cam 1, flexible The gear 2 is sleeved on the outside of the cam bearing 7, and the outer ring gear 8 of the flexible gear 2 is partially meshed with the inner ring gear 9 of the rigid gear 4.

[0022] Further, an adapter plate 16 is connected to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com