Differential Hall multi-turn-position absolute position sensor and detection method thereof

An absolute position and sensor technology, which is applied in the direction of converting sensor output, using electric/magnetic devices to transmit sensing components, instruments, etc., can solve problems such as service life, measurement accuracy and transmission influence of measurement signals, and achieve strong anti-interference ability , Reliable effect of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

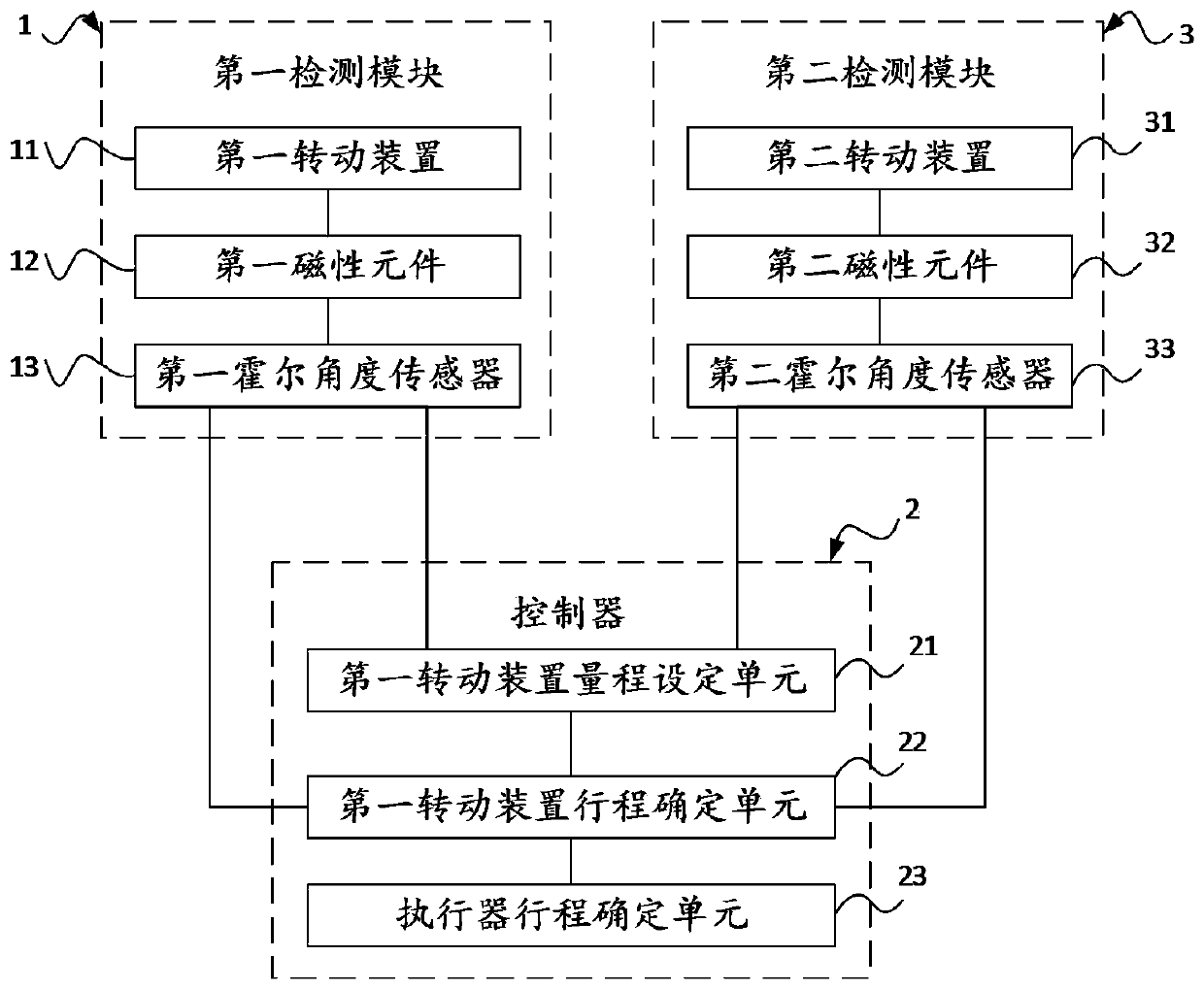

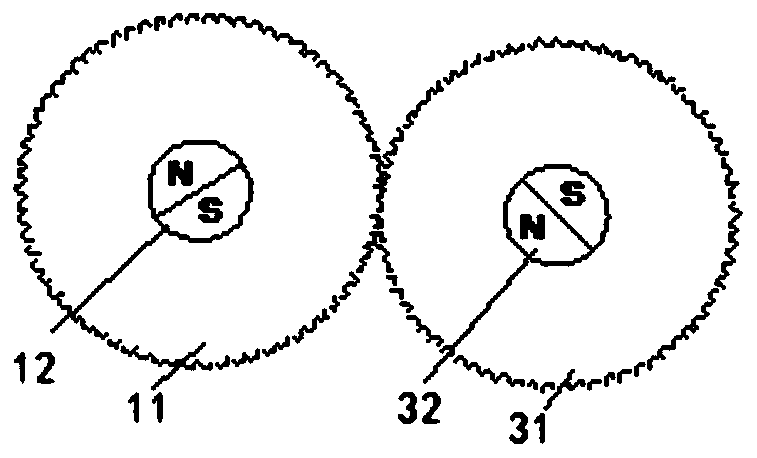

[0054] An embodiment of the present invention provides a differential Hall multi-turn position absolute position sensor, see figure 1 , including a differential Hall multi-turn position absolute position sensor, including a first detection module 1 and a controller 2, the first detection module includes a first rotating device 11, a first magnetic element 12 and a first Hall angle sensor 13 ,

[0055] The first rotating device 11 is connected with the output shaft of the actuator, and rotates under the drive of the output shaft with the set first transmission ratio;

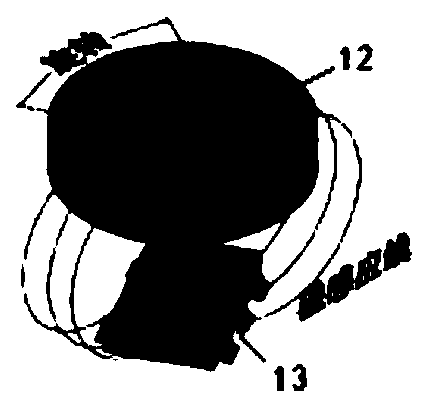

[0056] The first magnetic element 12 is arranged on the first rotating device 11 to generate a magnetic field around the first rotating device 11;

[0057] The first Hall angle sensor 13, corresponding to the first magnetic element 12, detects the magnetic field direction of the first magnetic element 12 in real time, and obtains the first angle of rotation of the first rotating device 11 in real time. ;

[00...

Embodiment 2

[0092] Embodiment 2. A detection method of the above-mentioned differential Hall multi-turn position absolute position sensor, comprising the following steps:

[0093] Step 1a: The first Hall angle sensor 13 detects the magnetic field direction of the first magnetic element 12 in real time, so as to obtain the first angle of rotation of the first rotating device 11 in real time; and send the first angle to the controller 2; Wherein, the first rotating device 11 is connected with the output shaft of the actuator, and rotates under the drive of the output shaft with the set first transmission ratio; the first magnetic element 12 is arranged on the first rotating device 11, so as to generating a magnetic field around the first rotating device 11;

[0094] Step 2a: The controller 2 receives the first angle, and calculates the stroke of the actuator according to the first angle.

[0095] Because the first Hall angle sensor 13 can only detect the deviation angle of the first magnet...

Embodiment 3

[0098] Embodiment 3, a detection method of the above-mentioned differential Hall multi-turn position absolute position sensor, comprising the following steps:

[0099] Step 1b: the first Hall angle sensor 13 detects the magnetic field direction of the first magnetic element 12 in real time, so as to obtain the first angle of rotation of the first rotating device 11 in real time; and send the first angle to the controller 2; Wherein, the first rotating device 11 is connected with the output shaft of the actuator, and rotates under the drive of the output shaft with the set first transmission ratio; the first magnetic element 12 is arranged on the first rotating device 11, so as to A magnetic field is generated around the first rotating device 11;

[0100] Step 2b: the second Hall angle sensor 33 detects the magnetic field direction of the second magnetic element 32 in real time, so as to obtain the second angle of rotation of the second rotating device 31 in real time; and send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com