Rotating electric machine

A technology for rotating electrical machines and rotors, which is applied in the direction of motors, electromechanical devices, electric vehicles, etc., and can solve problems such as inability to ensure oil flow rate, oil entry, and uneven cooling of coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0047]

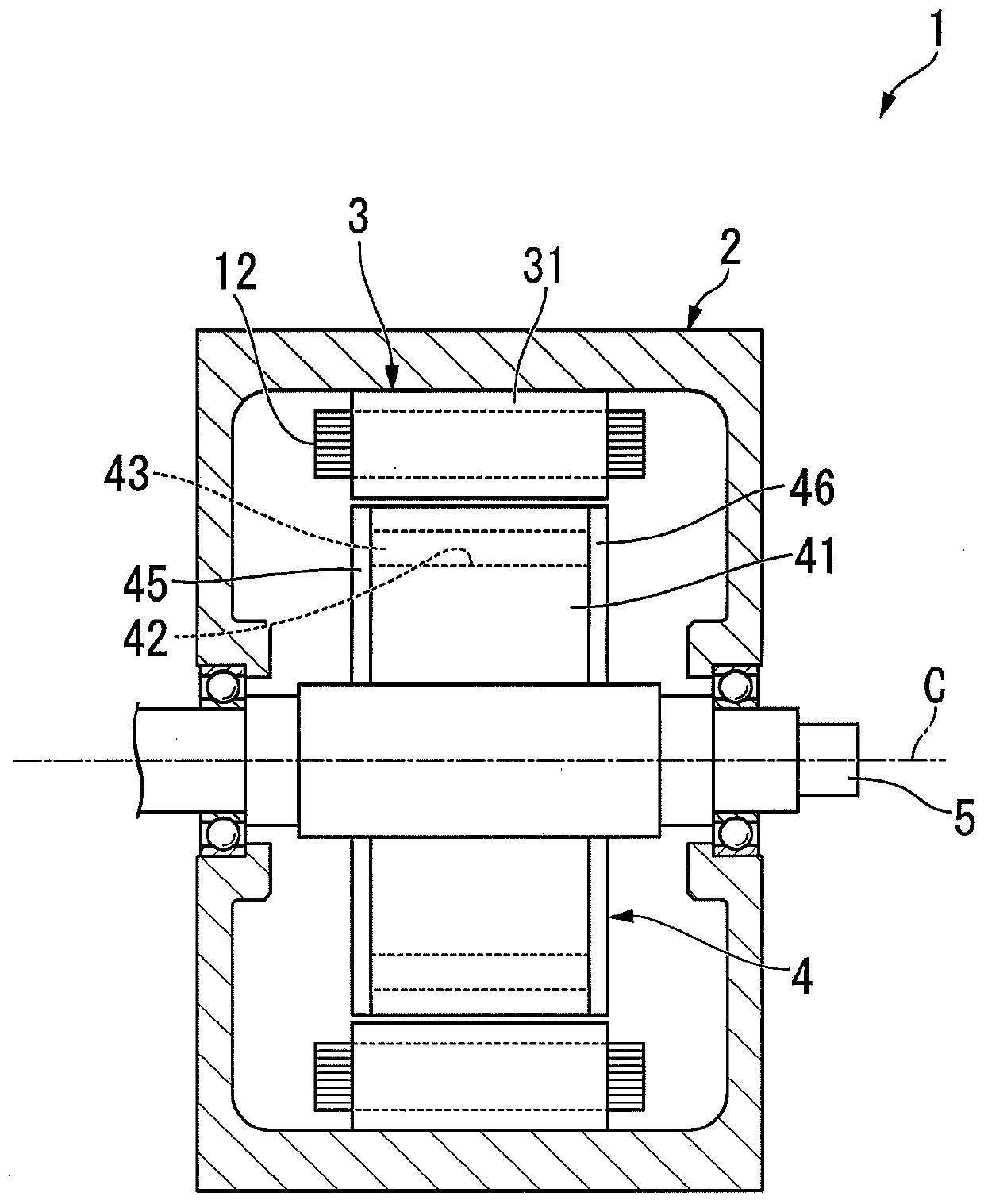

[0048] figure 1 It is a cross-sectional view showing a schematic configuration of the rotating electrical machine of the embodiment.

[0049] figure 1 The rotating electric machine 1 shown is, for example, a running motor mounted in a vehicle such as a hybrid vehicle or an electric vehicle. However, the configuration of the present invention is not limited to traveling motors, and can be applied to motors for power generation, motors for other purposes, and rotating electric machines (including generators) other than vehicles.

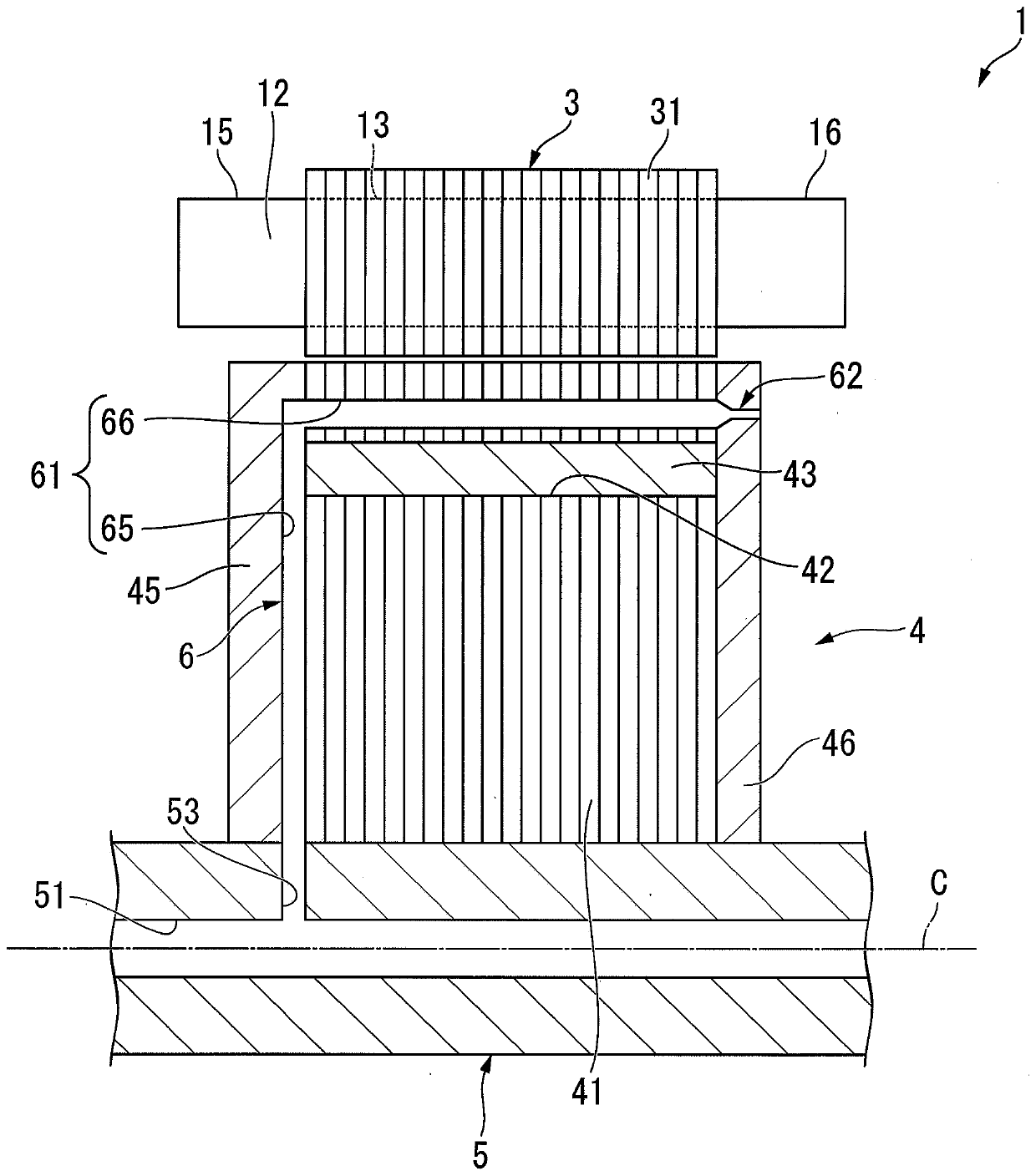

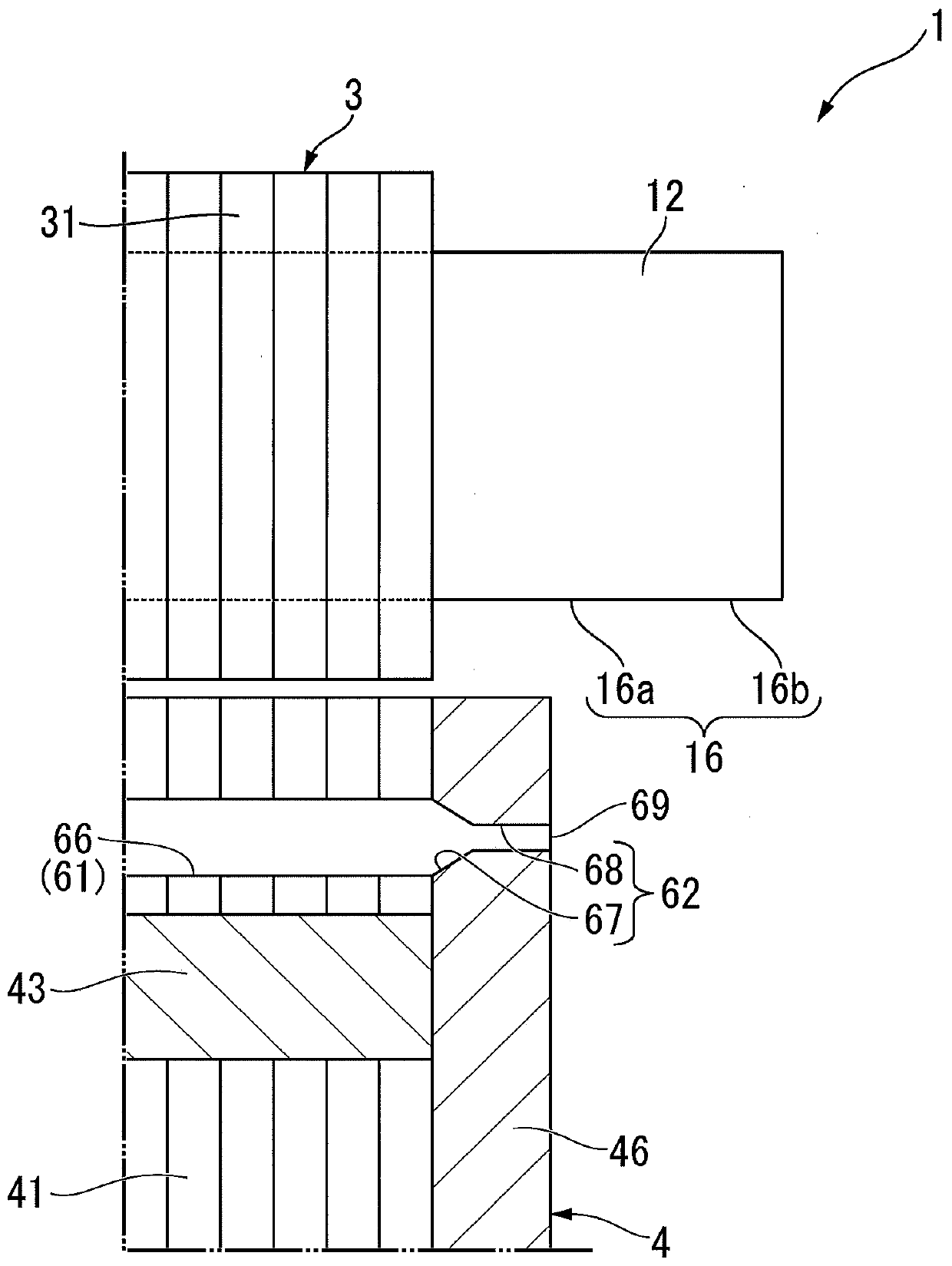

[0050] The rotary electric machine 1 includes a case 2, a stator 3, a rotor 4, an output shaft 5, and a refrigerant flow path 6 (see figure 2 ).

[0051] The casing 2 accommodates the stator 3 , the rotor 4 and the output shaft 5 . Refrigerant (not shown) is accommodated inside the casing 2 . The above-mentioned stator 3 is arranged in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com