Double-walled vacuum glass thermos flask

A vacuum glass, double-layer vacuum technology, applied in non-pressure vessels, household appliances, fixed-capacity gas storage tanks, etc., can solve the problem of not providing the possibility of vacuuming, and achieve the effect of saving material costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

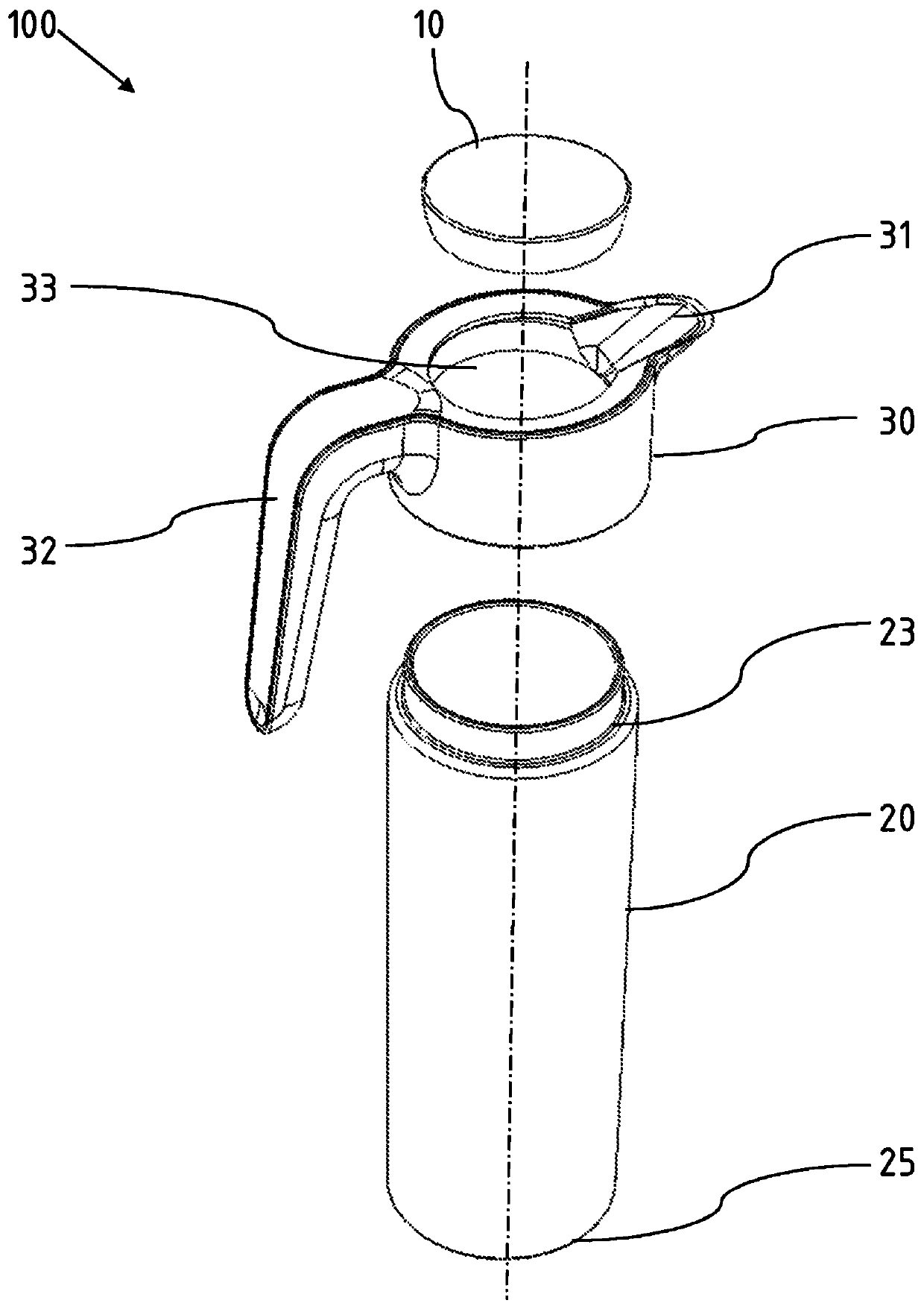

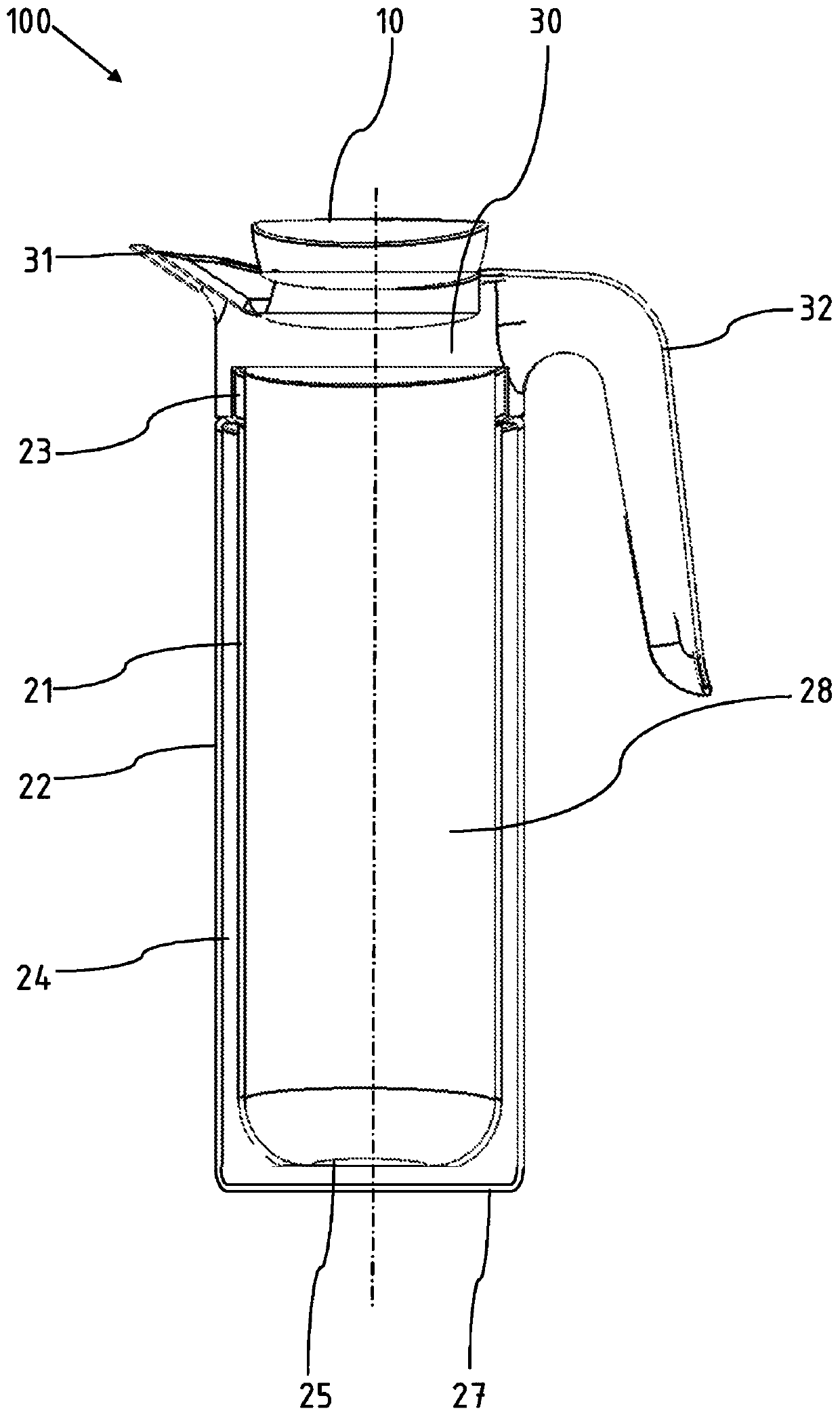

[0025] figure 1 The thermos jug 100 is shown as a perspective exploded view. Here, a version with handle 32 is depicted. The thermos 100 consists of three mutually detachable components, namely a hollow glass body 20 , a pouring tip 30 with a handle 32 and a lid 10 , which are presented separately from each other according to the invention.

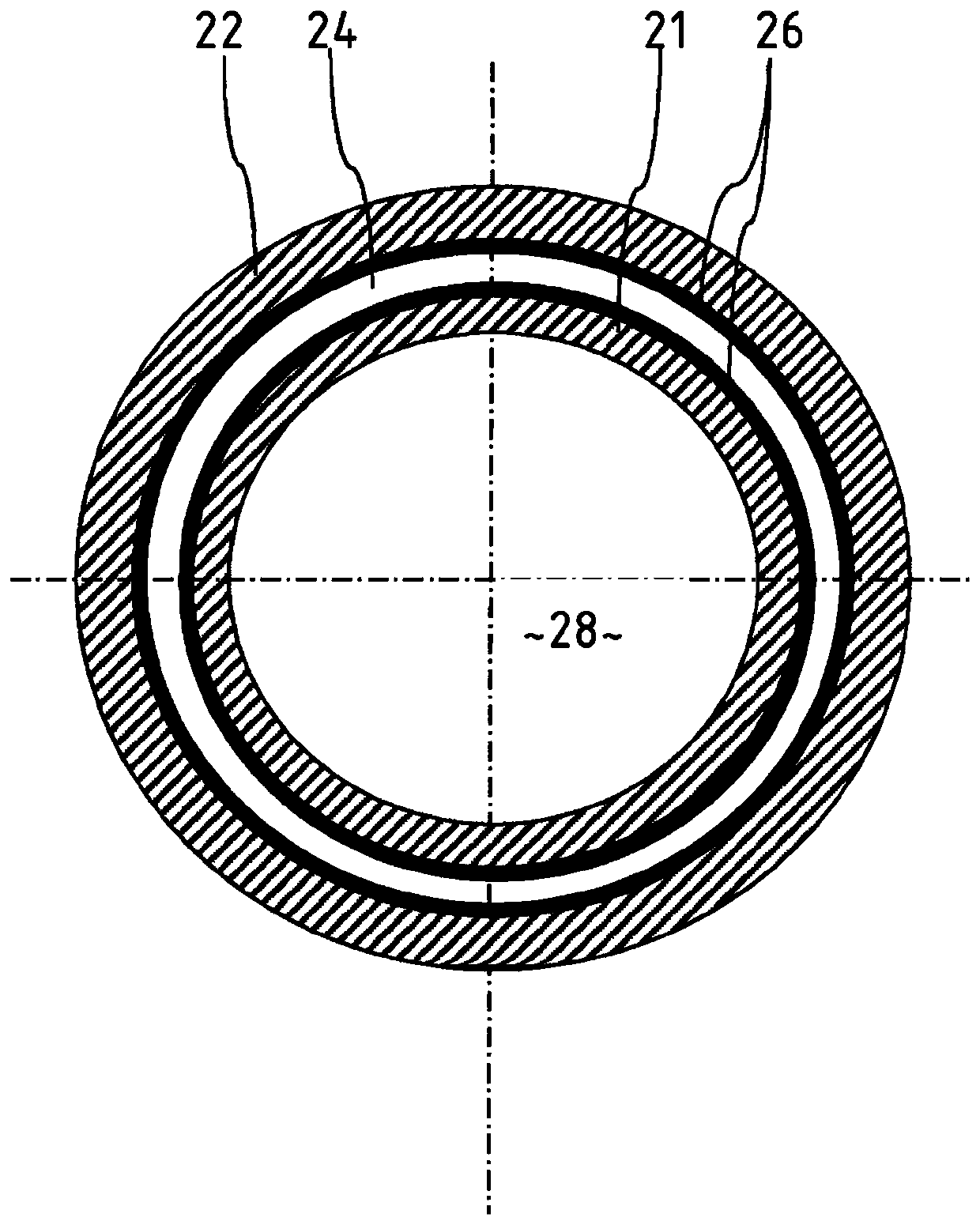

[0026] The hollow glass body 20 has an elongated cylindrical shape and is made entirely of borosilicate glass. The hollow glass body 20 is closed at one end with a bottom plate 25 . At the opposite upper end, the hollow glass body 20 is opened and formed with connecting means, such as in particular pressed The kettle neck 23 of external thread.

[0027] In addition to the hollow glass body 20, in figure 1 Also shown is the pouring tip 30. The pouring tip is a plastic threaded screw cap which is screwed onto the hollow glass body 20 .

[0028] The pouring tip 30 is designed in the form of a ring and has a central pouring opening 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com