Pulverizing, shred kneading, screw compressing and compacting straw returning machine

A spiral and straw technology, applied in the field of agricultural engineering, can solve the problems of the soil organic matter content in the soil layer is not obvious, the seeds cannot be in good contact with the soil, and the passability is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

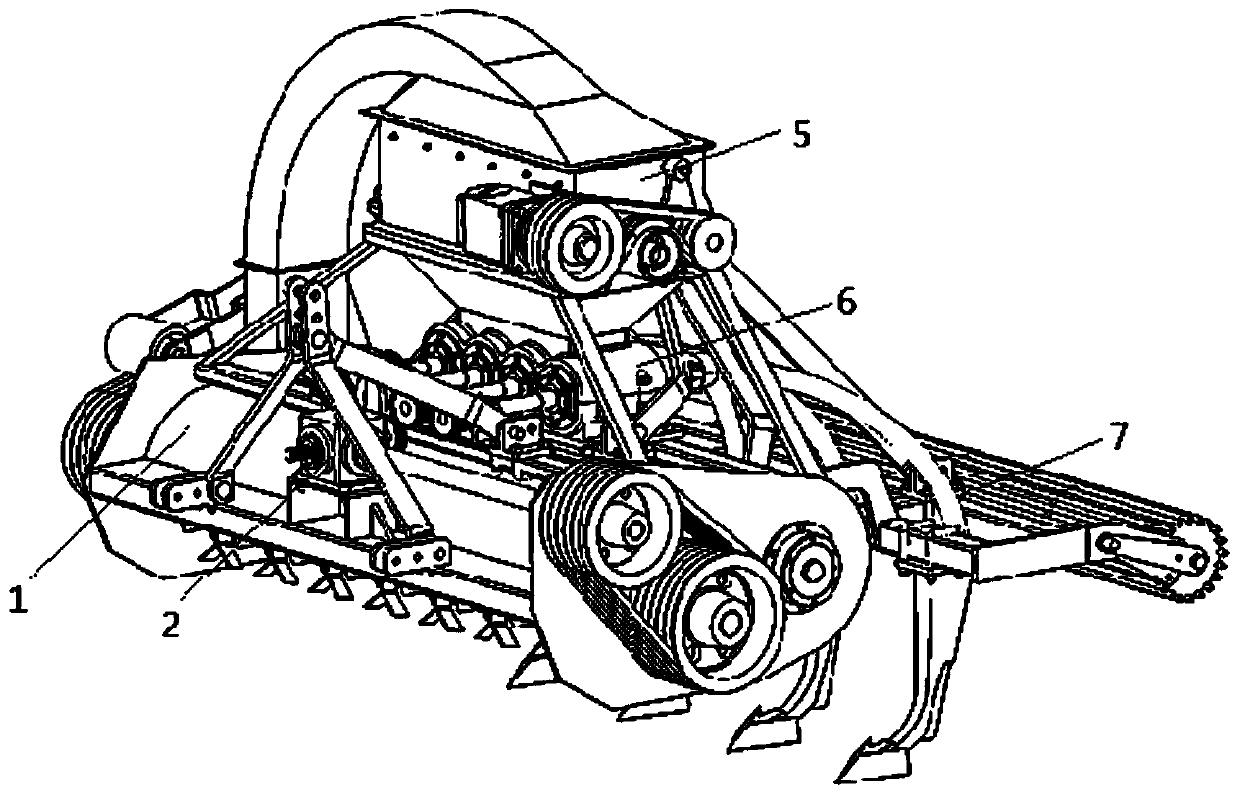

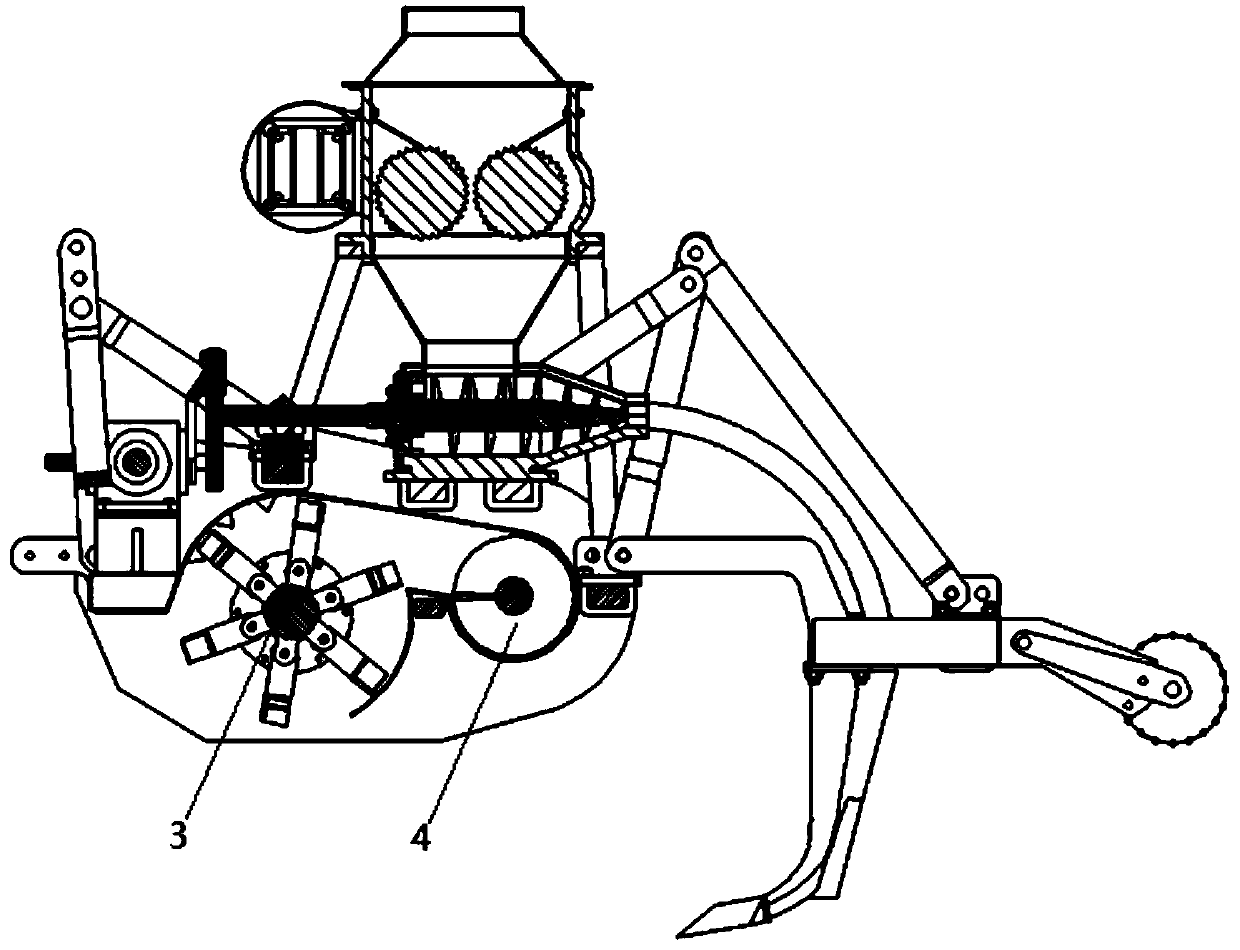

[0105] Such as figure 1 , 2 As shown, the present invention provides a crushing and kneading silk screw compression and densification returning machine, which includes a returning machine casing 1, a power transmission device 2, a picking and chopping device 3, a screw conveying and blowing device 4, and a shredded and thinned device 5. Screw compression device 6. Subsoiling and deep burial device 7.

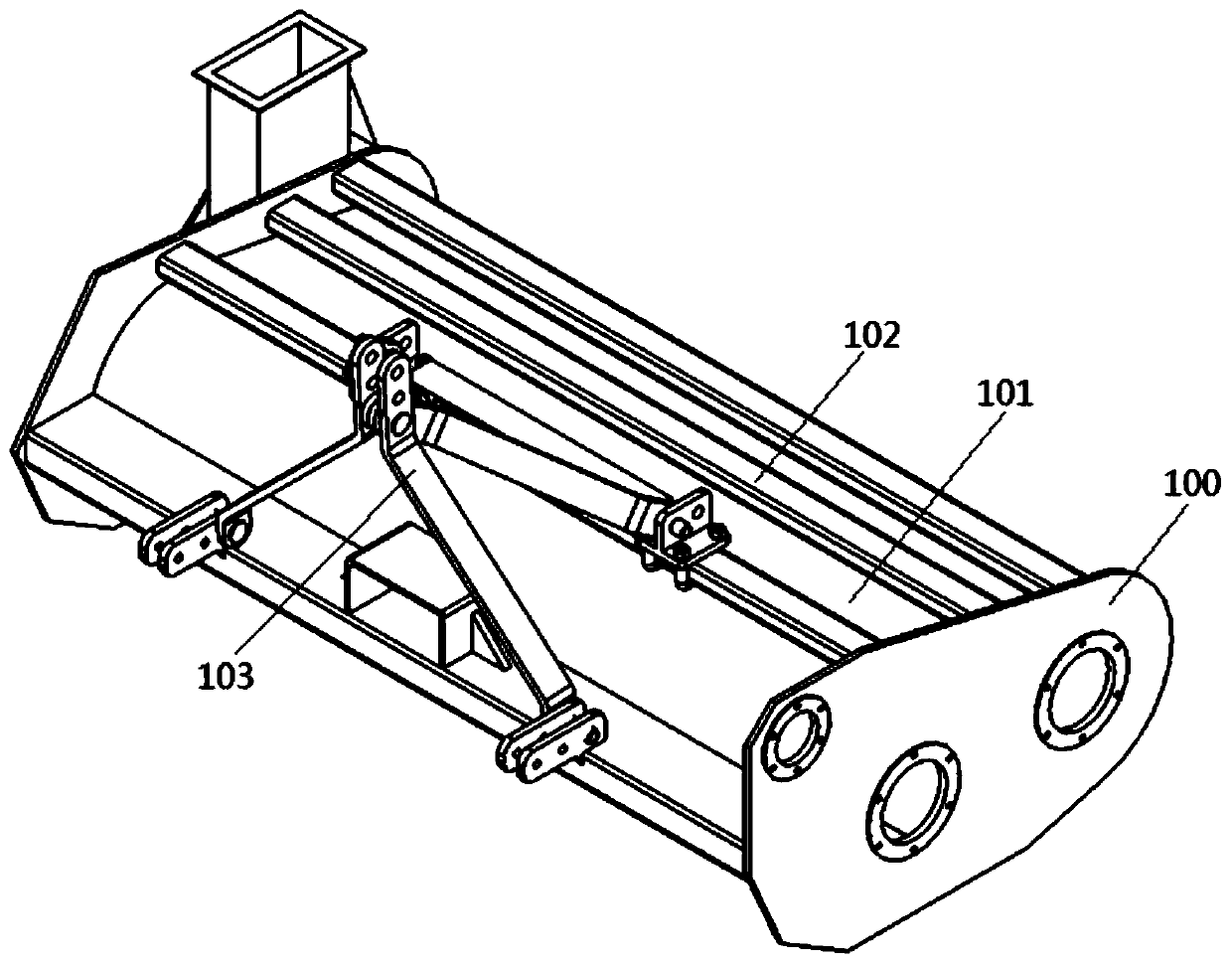

[0106] Such as image 3 As shown, the casing 1 of the field returning machine includes a side plate 100 , a plate-shaped steel material 101 , a beam 102 , and a three-point suspension rod 103 . The shell of the field returning machine is welded by several side plates 100, plate-shaped steel 101 and cross beam 102, and the three-point suspension rod 103 is hinged to the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com