Workpiece detecting and sorting device and method based on visual robot

A workpiece detection and visual detection technology, applied in sorting, instrument, image analysis and other directions, can solve the problems of low resolution and small image, and achieve the effect of improving the accuracy, good detection accuracy and real-time effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

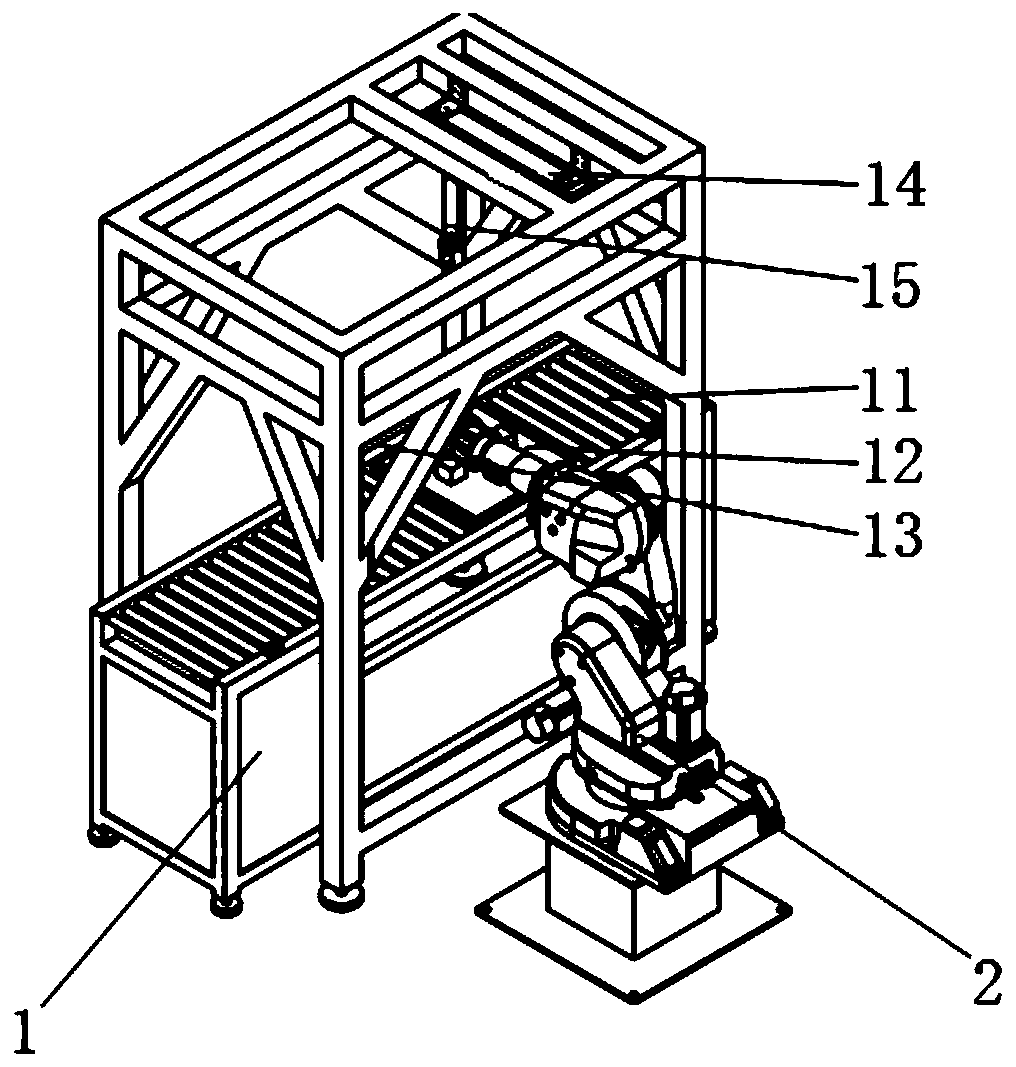

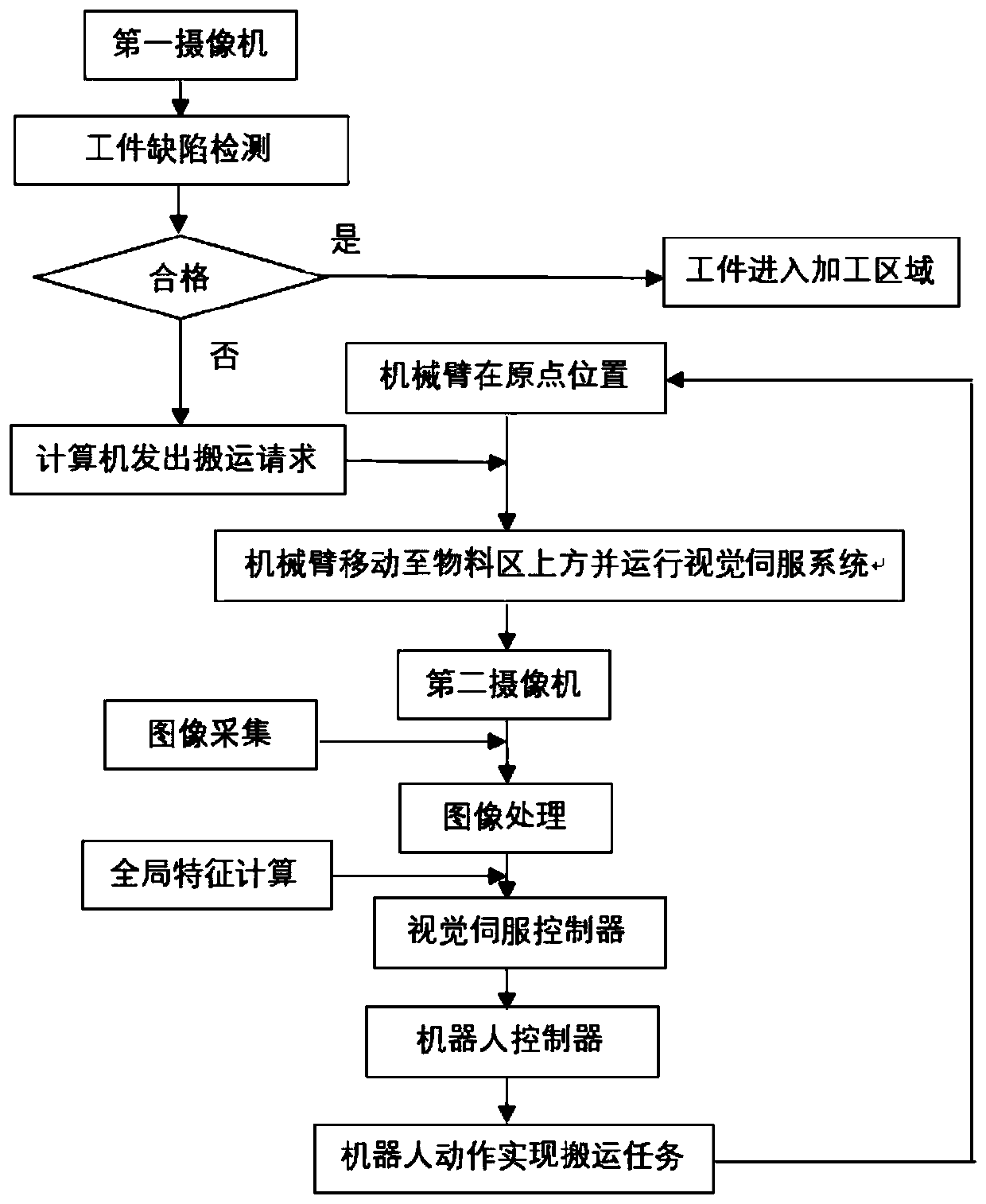

[0043] A device and method for detecting and sorting workpieces based on visual robots in the present invention mainly solves the problem of accurately detecting and classifying surface defects of workpieces by visual robots before sorting and transporting workpieces in the post-processing process of workpieces, and then judging whether workpieces are Qualified, and move the non-conforming products to the waste bin.

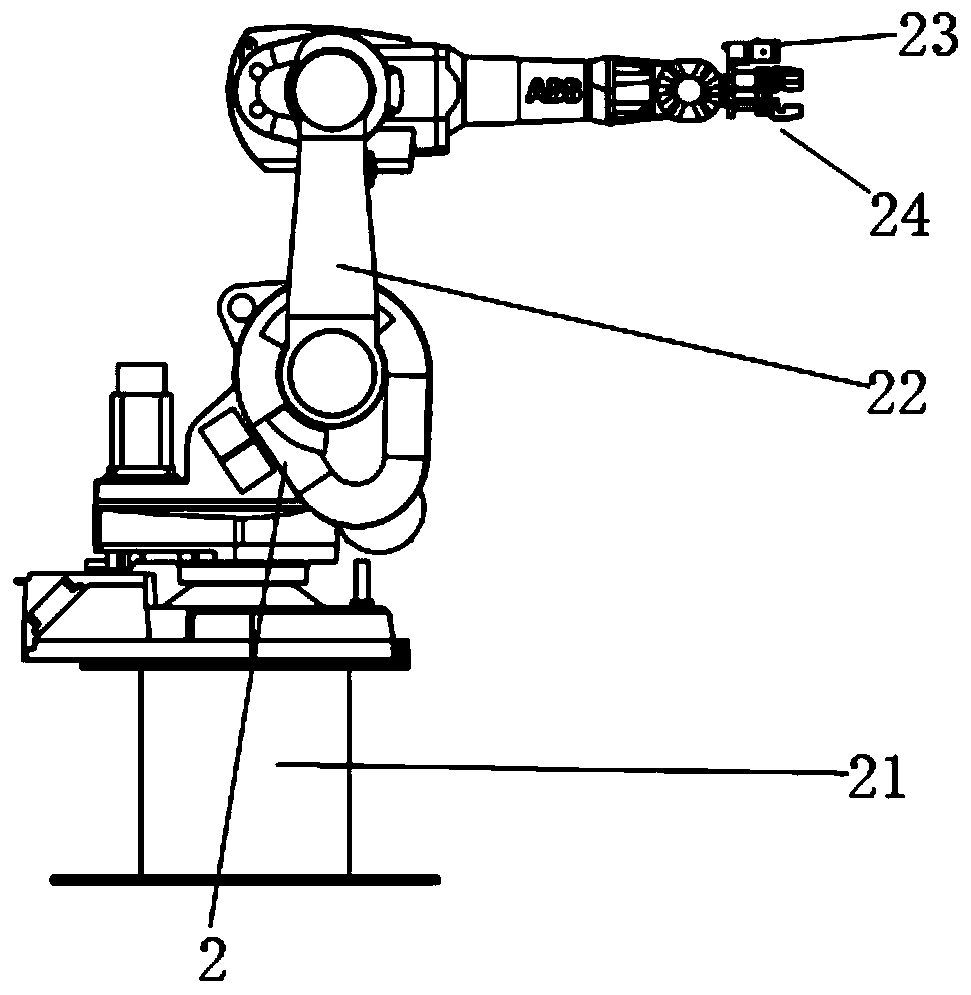

[0044] The visual experiment platform of the detection and sorting system mainly consists of a light source, a camera, an image acquisition card, and a robot 2. A first camera 15 is installed above the visual inspection area, and a second camera 23 is installed on the actuator 24 at the end of the robot 2 .

[0045] The first camera 15 completes the shooting of the casting and performs defect detection and classificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com