Protective device and method of hot rolled strip steel lower surface detecting device

A technology for surface detection and hot-rolled strip steel, which is applied to workpiece surface treatment equipment, length measuring devices, workpiece cleaning devices, etc., can solve problems such as splashing of water droplets, inability to ensure the cleaning of protective glass, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

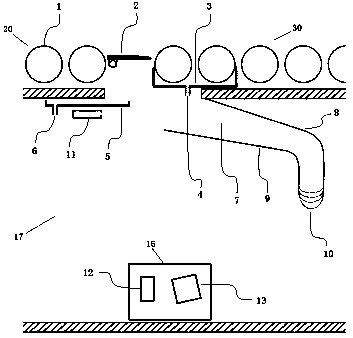

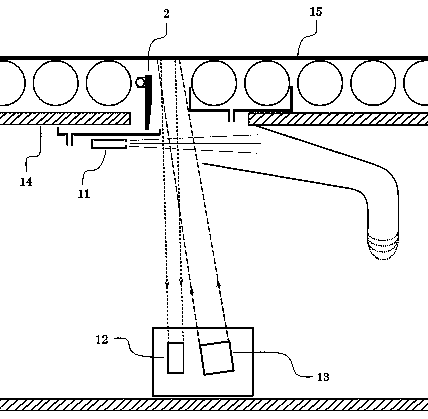

[0021] In this example, refer to the attached figure 1 , 2 , the centerline of the roller table flap 2 is 10-30mm lower than the centerlines of the conveying roller table A20 and the conveying roller table B30, and the gap between the roller table flap 2 and the conveying rollers on both sides is ≤10mm.

[0022] The detection equipment for the lower surface of the steel strip is all arranged in the equipment room 17, and the conveying roller table A20 and the conveying roller table B30 are arranged on the roof 14 of the equipment room, and the equipment room roof 14 is provided with a The distance matches the hole, and the size of the hole can meet the requirements of the detection equipment beam.

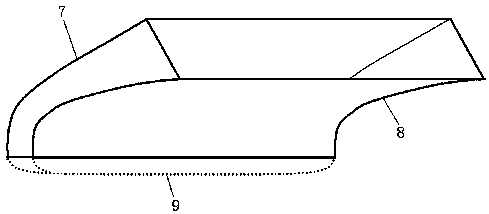

[0023] The roller table roller groove 3 is set under the two conveying rollers close to the roller table flap 2 in the conveying roller table B30, and the bottom of the roller table roller groove 3 has a roller groove drain outlet 4 with a diameter ≥ 50mm, and the roller groove dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com