Assembling and pressing mechanism for fan impeller automatic assembling production line

An automatic assembly and fan impeller technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of poor product processing consistency, high labor costs, low processing efficiency, etc., to achieve good safety, simple equipment structure, Good product process consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

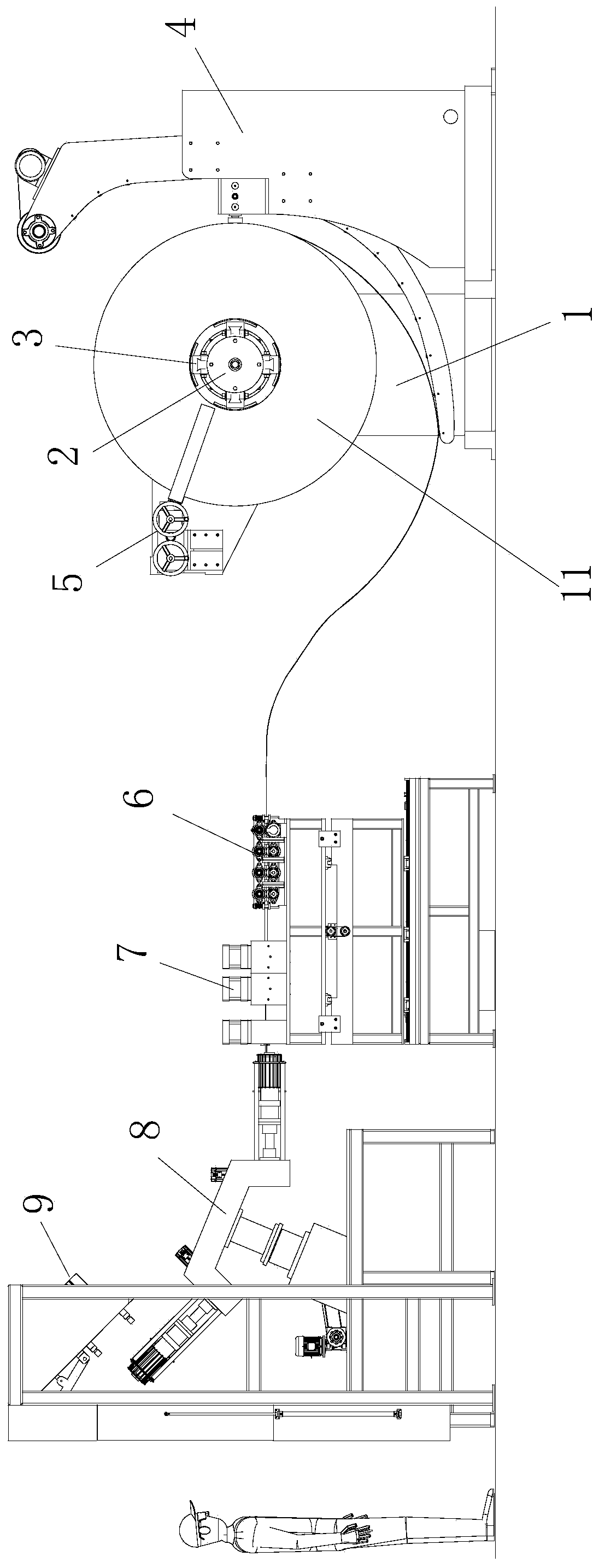

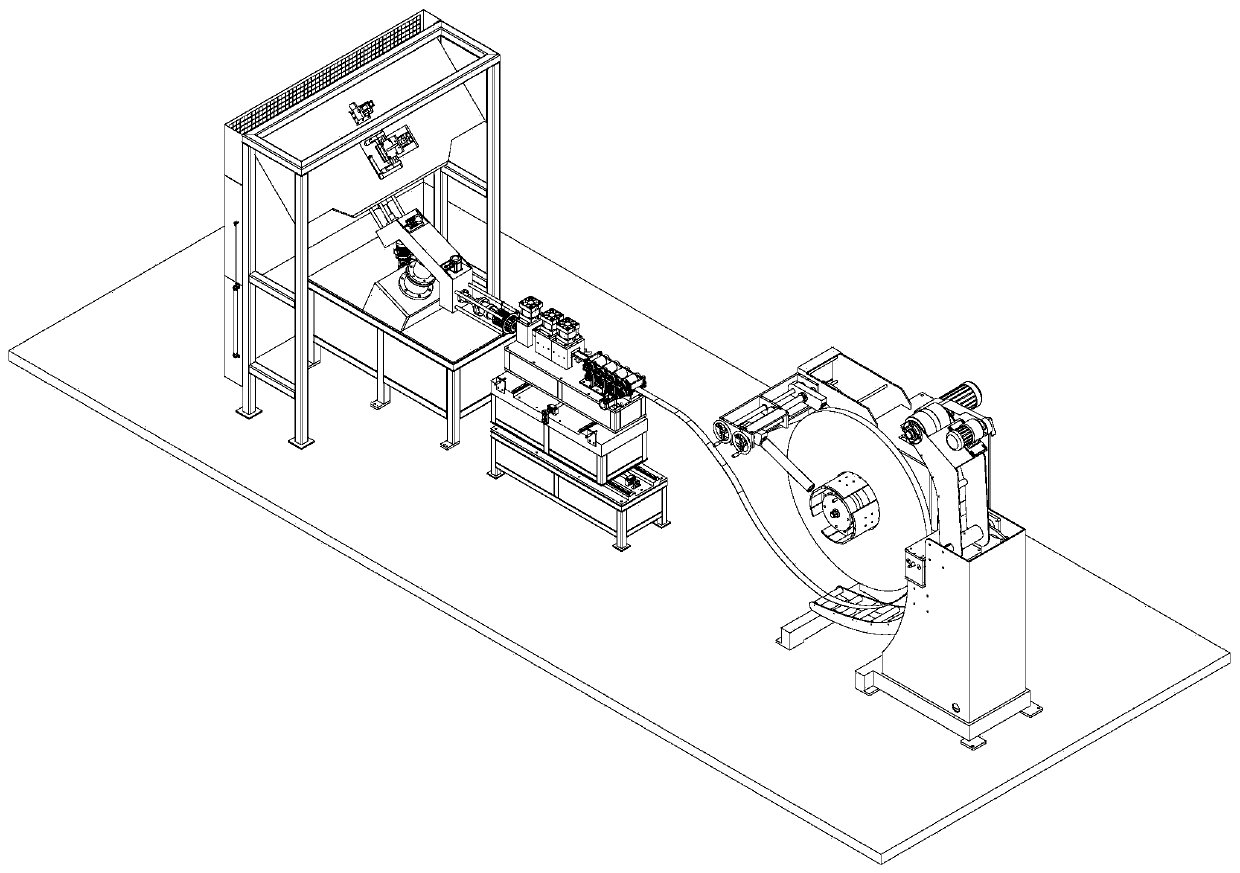

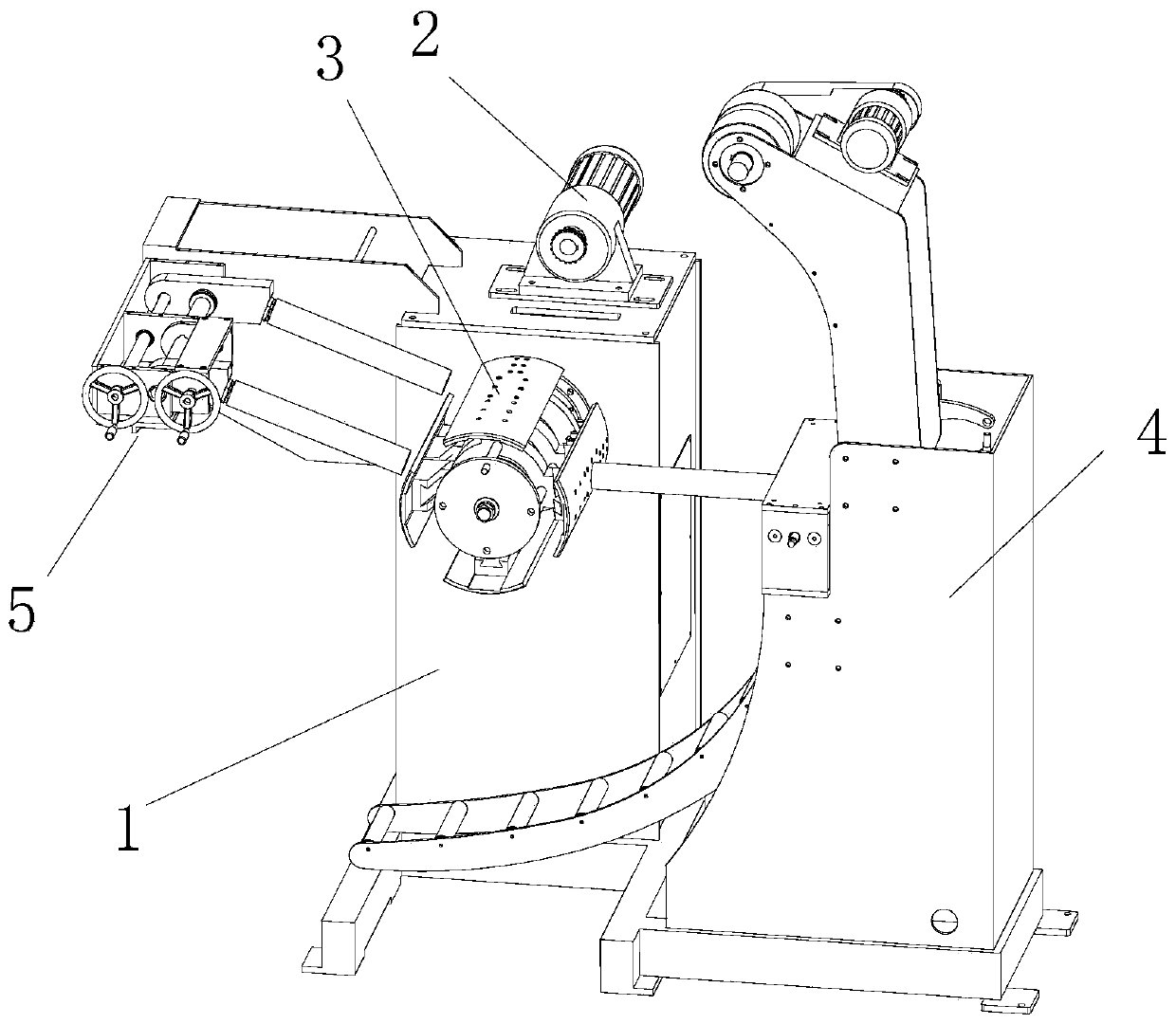

[0058] The assembly pressing mechanism provided by the present invention is a component in the fan impeller automatic assembly production line. In order to understand the technical content of this solution more easily, this embodiment describes in detail the assembly pressing mechanism itself on the basis of the entire automatic assembly production line, and The working principle and connection relationship with other components are as follows:

[0059] Such as figure 1 and figure 2 As shown, this embodiment discloses an automatic fan impeller assembly production line, which mainly includes a steel strip uncoiling mechanism, a blade roll forming feeding mechanism 6, a blade punching mechanism 7, and a double-station rotary assembly mechanism arranged in sequence. 8. And the pressing material loading and unloading mechanism 9. The worker puts the steel strip coil material into coils into the steel strip uncoiling mechanism, and the steel strip head extends into the blade rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com