Micro-nano dual-mode detection processing module

A micro-nano and electric displacement technology, applied in the direction of nanotechnology, microstructure technology, microstructure device, etc., can solve the problems of processing system motion precision, workpiece installation, adjustment precision, cutting precision and difficult machining requirements of cutting tools, and achieve low cost and simple structure , Improve the effect of lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

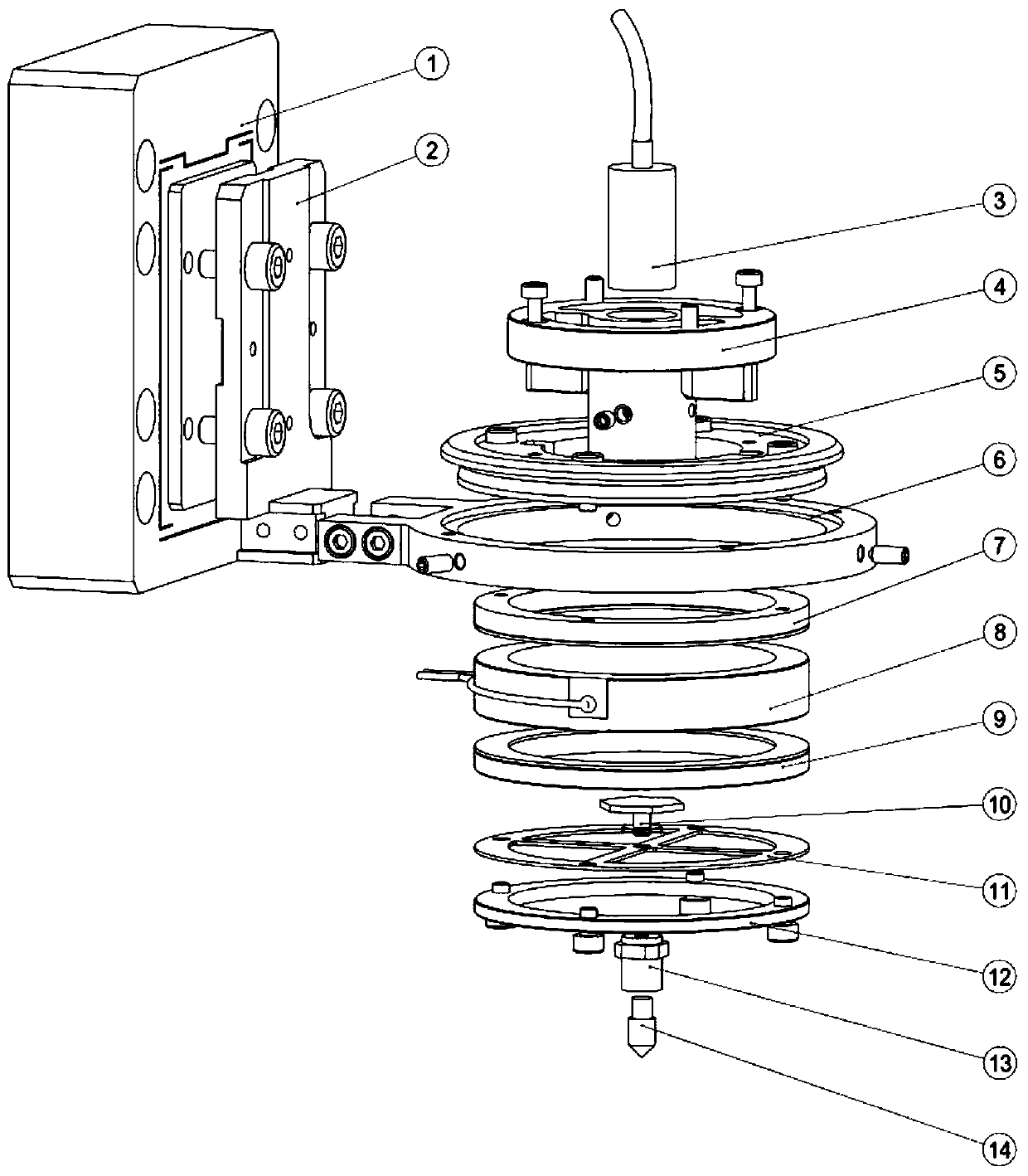

[0033] The invention discloses a micro-nano dual-mode detection and processing module, such as figure 1 As shown, the module includes a Z-direction piezoelectric displacement table 1, a bracket 2, a capacitive displacement sensor 3, a capacitor fixing seat 4, an adjusting seat 5, a locking support 6, an upper fixing ring 7, a PZT vibrator 8, Lower fixing ring 9, test screw 10, flexible hinge 11, stop ring 12, fixing nut 13 and probe 14, wherein:

[0034] The capacitive displacement sensor 3 passes through the second set screw 17 ( Figure 11 ) is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com