High-strength gypsum-based self-leveling mortar and preparation method thereof

A self-leveling mortar and gypsum-based technology, applied in the field of inorganic non-metallic materials and building materials, can solve the problem of high strength of gypsum-based self-leveling mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

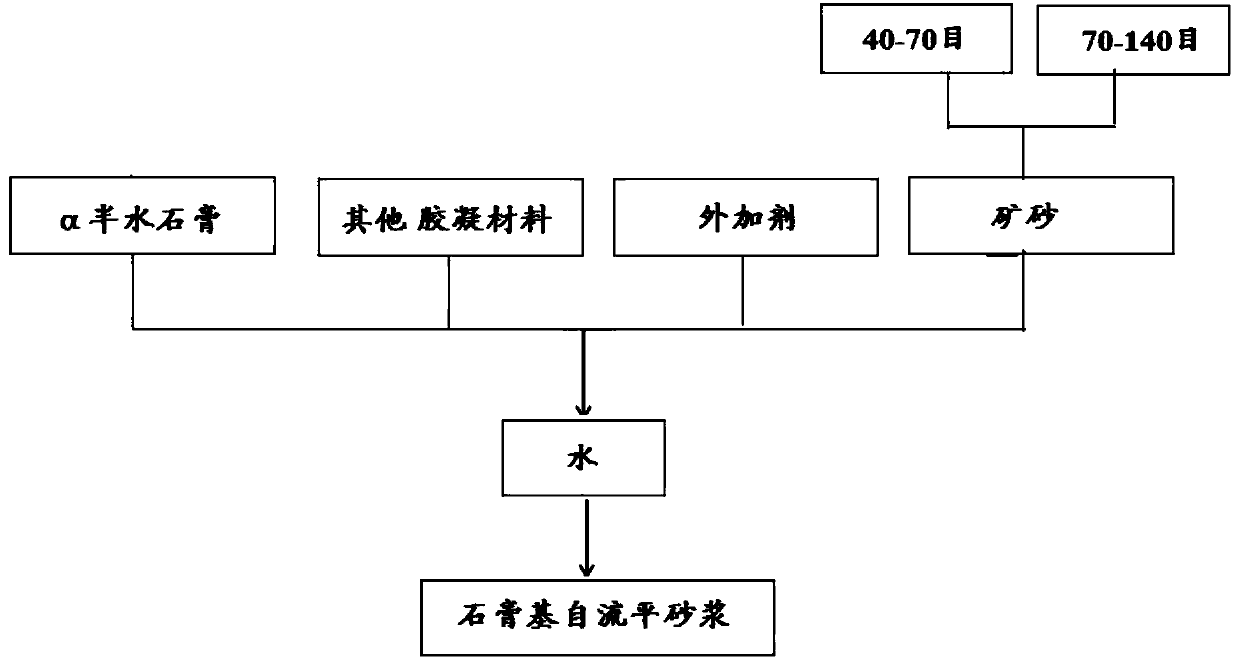

[0021] The embodiment of the present application provides a preparation method of high-strength gypsum-based self-leveling mortar, such as figure 1 As shown, the shown method includes the following steps: mixing α hemihydrate gypsum, other cementitious materials except α hemihydrate gypsum, fineness of 40-70 mesh and 70-140 mesh ore and admixture evenly, Add water, soak for a period of time, stir for a period of time. The gypsum-based self-leveling mortar was obtained.

[0022] Preparation of gypsum-based self-leveling mortar:

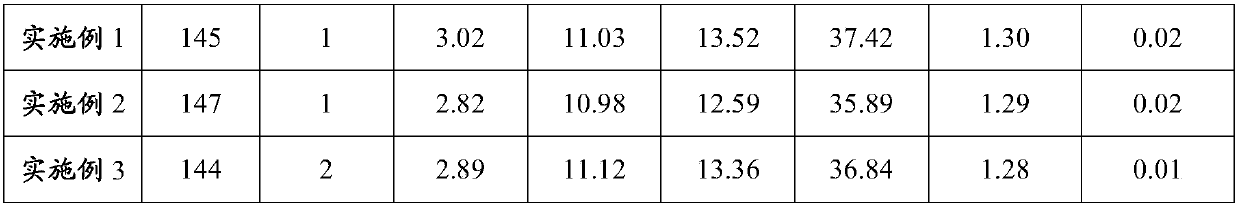

Embodiment 1

[0024] (1) Take 1360 grams of α hemihydrate gypsum, 600 grams of 40-70 mesh mineral sand, 600 grams of 70-140 mesh mineral sand, 200 grams of cement, 400 grams of heavy calcium, 80 grams of rubber powder, 4.8 grams of water reducing agent, retarder 0.8 grams of agent, 1.6 grams of water retaining agent, 1.6 grams of defoamer, mix well.

[0025] (2) Add the uniformly mixed mixture in step (1) into 720ml of water, soak for 30s, and stir for 3min to prepare a gypsum-based self-leveling mortar.

Embodiment 2

[0027] (1) Take 1200 grams of α hemihydrate gypsum, 638 grams of ore sand of 40-70 mesh, 637 grams of ore sand of 70-140 mesh, 188 grams of cement, 375 grams of heavy calcium, 75 grams of rubber powder, 5.6 grams of water reducing agent, retarding 0.75 grams of agent, 1.5 grams of water retaining agent, 1.5 grams of defoamer, mix well.

[0028] (2) Add the uniformly mixed mixture in step (1) into 638ml of water, soak for 40s, and stir for 4min to prepare a gypsum-based self-leveling mortar.

PUM

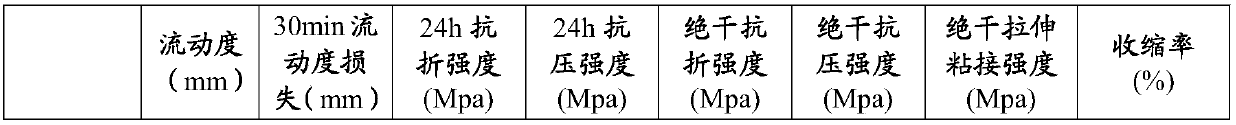

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com