Buoyancy control primary and secondary core pipe valve

A technology for controlling sub-tubes and core tubes, applied in the direction of sliding valves, valve details, valve devices, etc., can solve problems such as inconvenient installation and maintenance, large space occupied by float valves, frequent opening and closing actions, etc., to improve reliability And long-term effect, reduce the vertical activity space, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

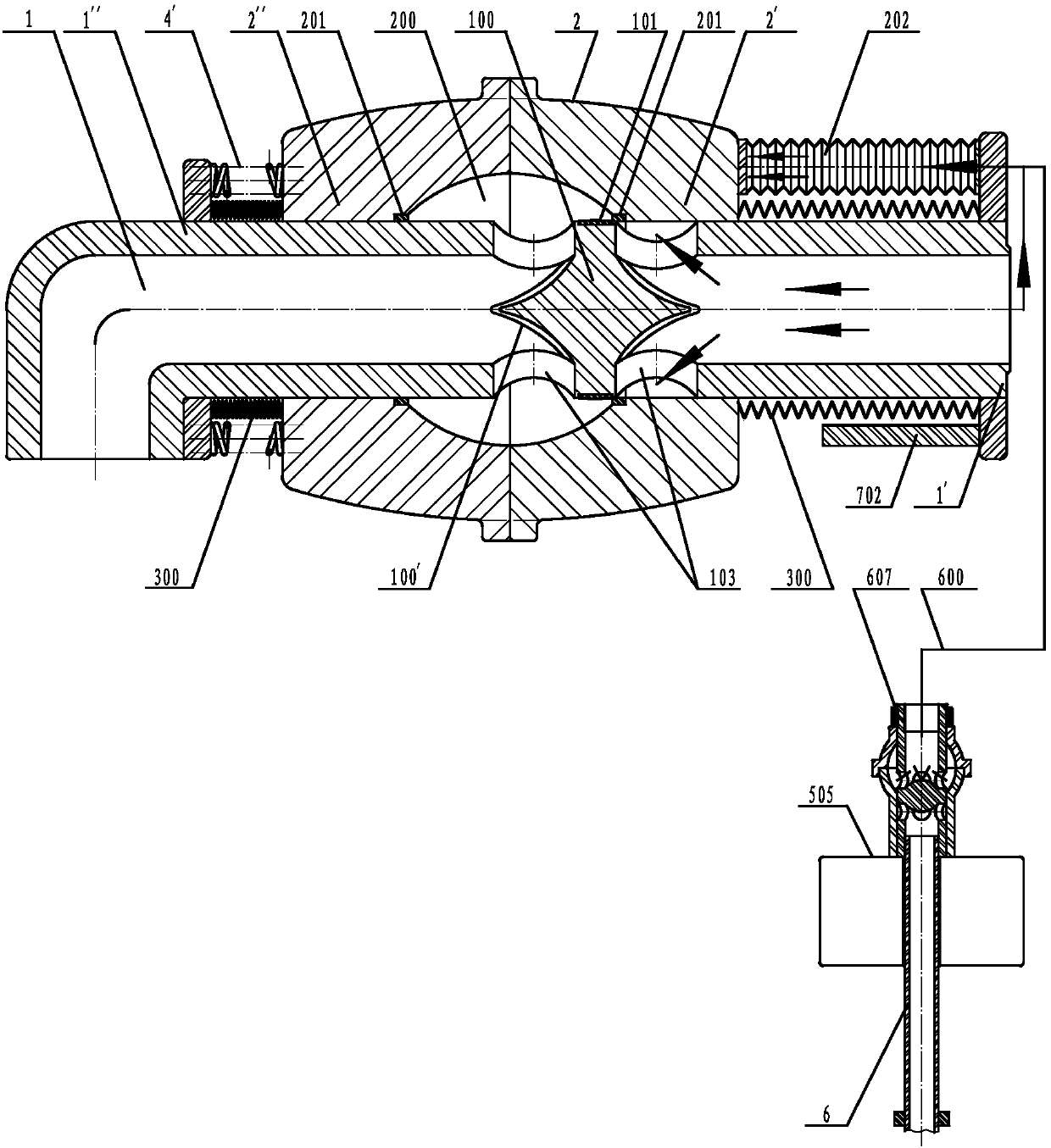

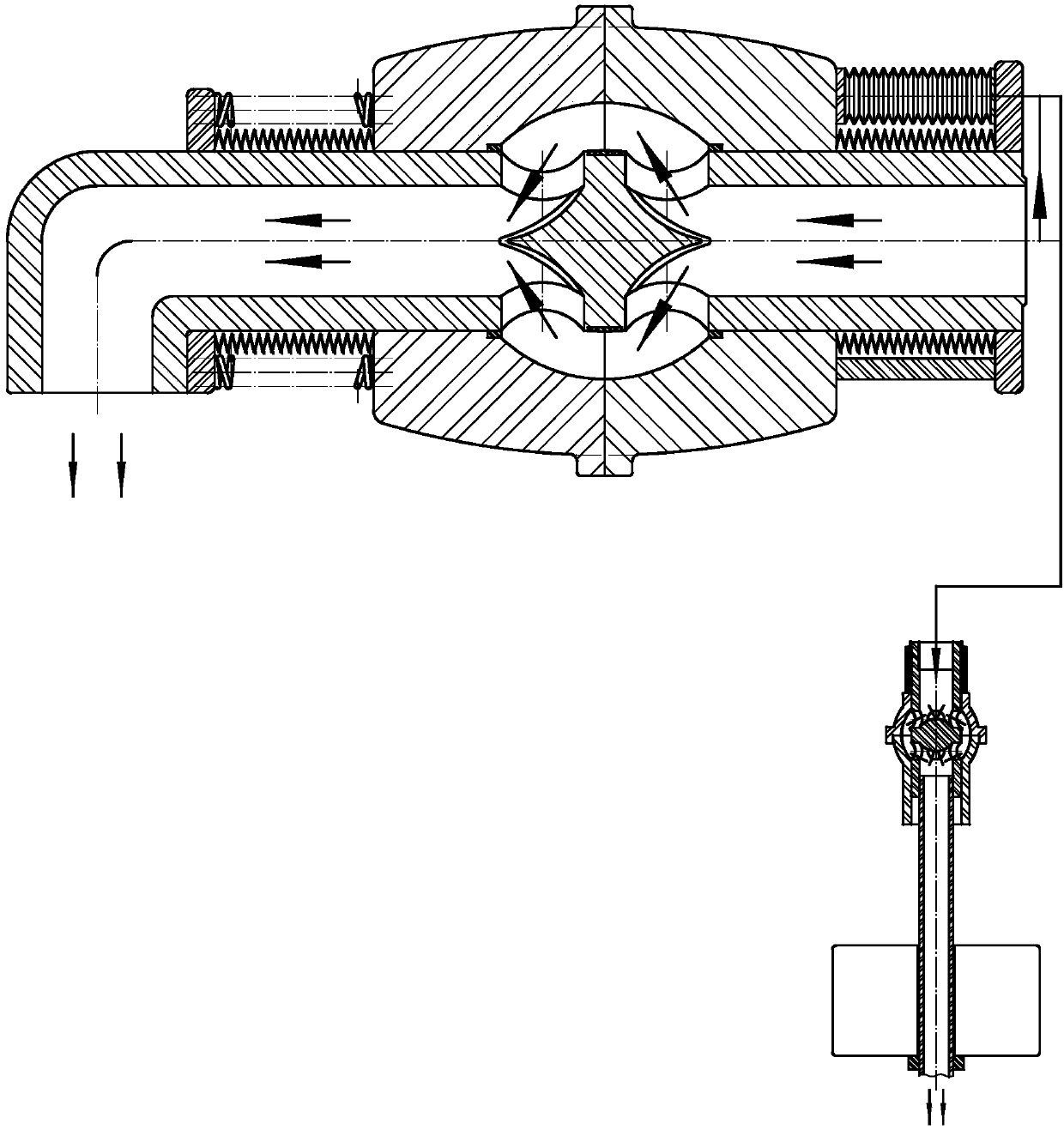

[0027] See attached figure 1 , 2 , the buoyancy control sub-mother core tube valve in this embodiment is a sub-mother valve group, and the discussion of the main valve is mainly discussed; the valve core tube 1 is a fixing piece that runs through the sleeve I2' of the valve body 2, and the inner cavity 200 of the valve body 2 , and the sleeve pipe II 2 "of the valve body 2; there is an axial partition 100 in the middle of the valve core tube 1, and the partition layer 100 is composed of the inner core and the middle section of the valve core tube 1 radially radiating from the inner core, and the two shafts of the core tube 100 The end face is a tongue-shaped triangular slope surface 100'; the axially adjacent two sides of the partition 100 are respectively two uniformly arranged radial flow holes 103 of the input section 1' and the output section 1"; surrounding and embedded in the partition 100 The sealing surface of the annular valve core 101 is a two-way slope surface and ...

Embodiment 2

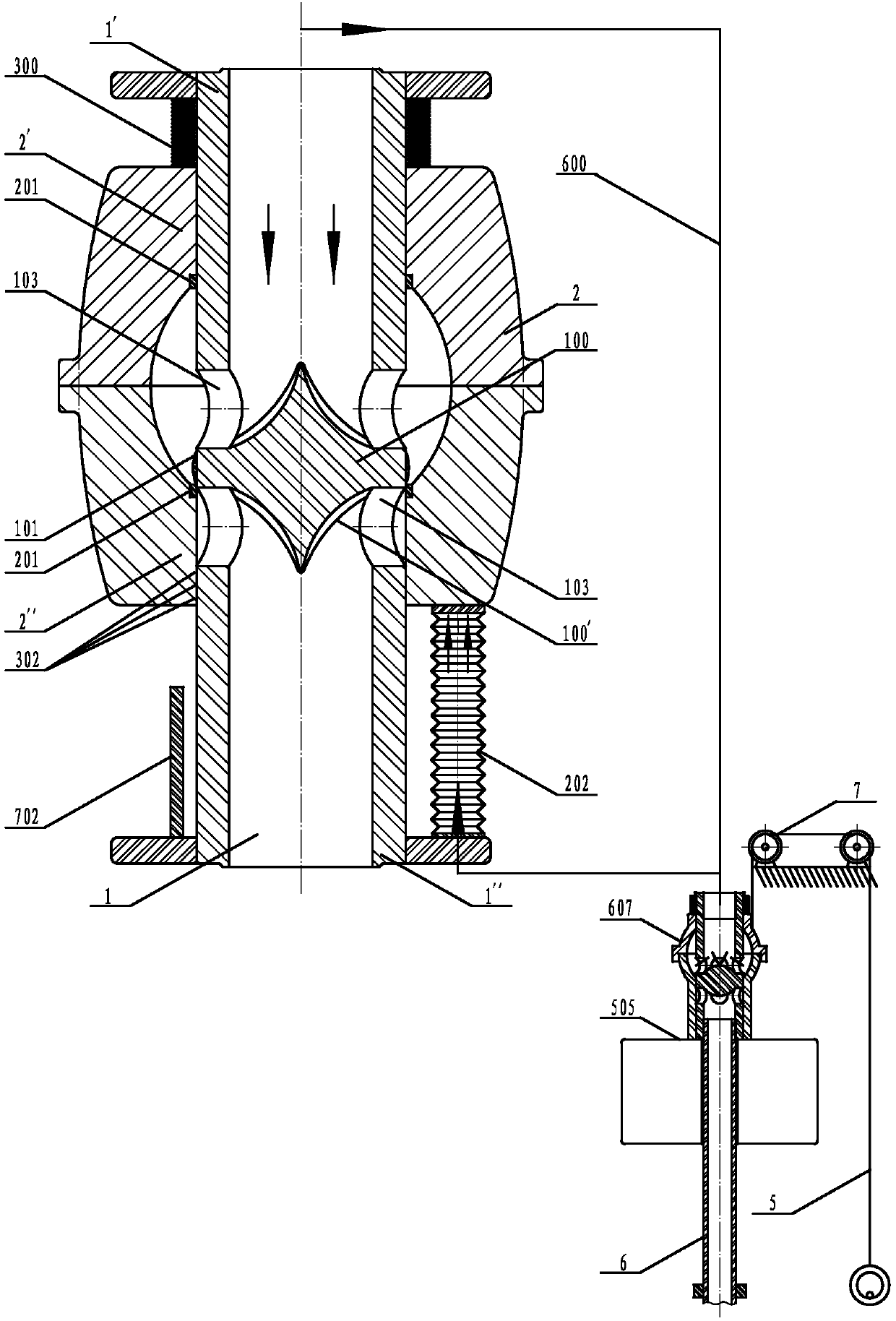

[0031] See attached image 3 , 4 , the buoyancy control sub-mother core pipe valve in this embodiment is a sub-mother valve group, and the main valve is mainly discussed; the valve core pipe 1 is a fixed part that is perpendicular to the ground and runs through the valve body 2 from top to bottom on the same axis. Sleeve I2', inner cavity 200 of valve body 2, and sleeve II2" of valve body 2; there is an axial partition 100 in the middle of the valve core tube 1, and the partition 100 is radially radiated from the inner core and the middle tube section of the valve core tube 1 Composition, the two axial end faces of the inner core of the interlayer 100 are tongue-shaped triangular slope surfaces 100'; the input section 1' and the output section 1" all have two uniformly arranged radial flow holes 103; the ring surrounding the interlayer 100 The sealing surface of the valve core 101 is a circular arc slope and the annular valve seat 201 at the throat of the sleeve pipe I2' and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com