Telescopic gas supply pipeline for slender combustion chamber

An air supply pipeline and combustion chamber technology, which is applied in the field of retractable air supply pipelines, can solve the problems such as the inability to effectively adjust the length and position of the gas supply pipeline of the burner, the inability to flexibly adjust the position of the heat source, and the limitation of the structure space of the combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

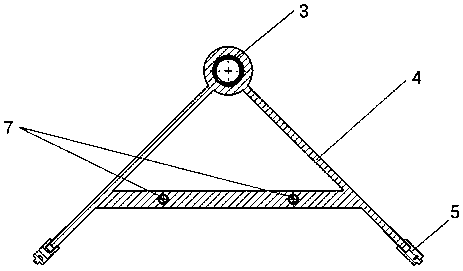

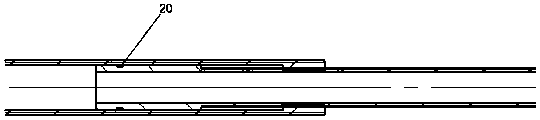

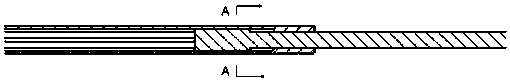

[0067] A telescopic air supply duct for a slender combustion chamber, the structure of which is as follows figure 1 As shown, it includes the outermost pipeline 1, the intermediate pipeline 2, the innermost pipeline 3, the guide structure 4, the support rod 5, the sleeve 6, the smallest diameter guide rod 7, the intermediate grade guide rod 8, the largest diameter guide rod 9, the first Second gear 10, frequency modulation motor 11, motor base 12, first flange 13, first gear 14, first bearing end cover 15, second bearing end cover 16, fixed rod 17, first sealing ring 18 of bearing end cover , The second sealing ring 19 of the bearing cover, the first sealing ring 20 of the pipeline, the second sealing ring 21 of the pipeline, the first cylindrical roller bearing 22 , the second cylindrical roller bearing 23 and the second flange 24 . figure 2 It is a top view of the overall structure of the pipeline.

[0068] Among them, among the outermost pipeline 1 , the intermediate pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com