A kind of anti-flame control method of gas stove

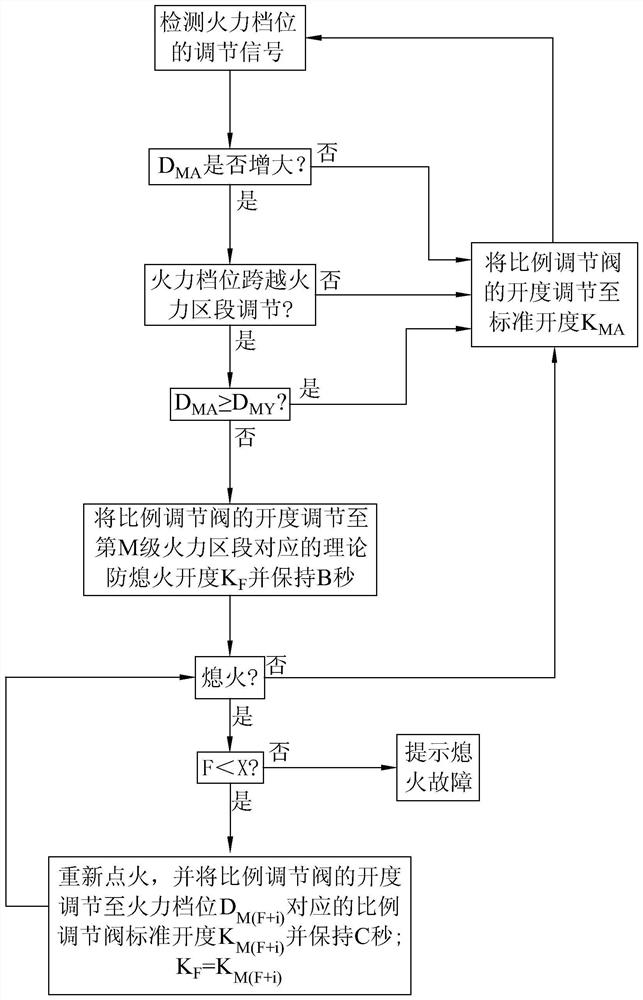

A control method and technology for gas stoves, applied in the field of gas stoves, can solve problems such as accidental flameout, poor flame uniformity, and inability to maintain flame combustion, and achieve the effects of ensuring uniformity and stability and improving success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

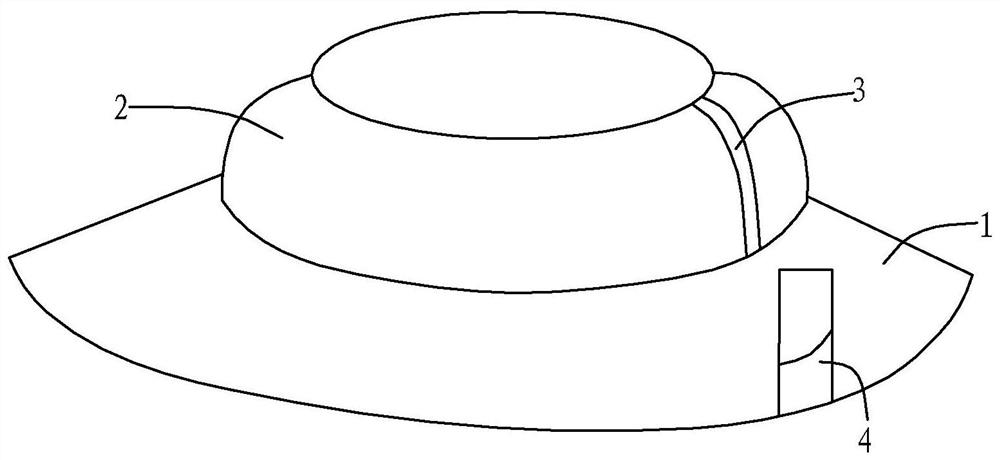

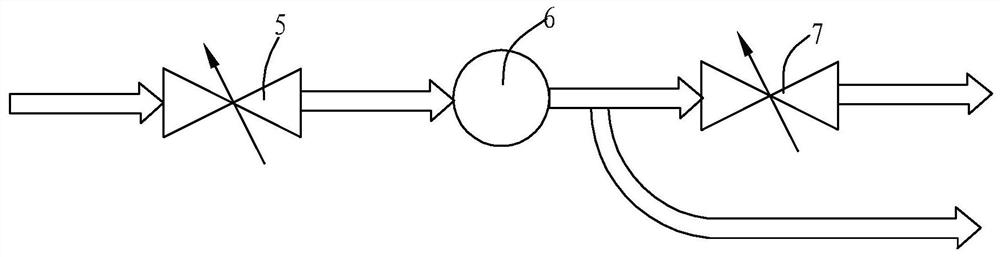

[0030] Existing gas stoves include N combustion chambers, gas pipelines and ignition pins, wherein N≥2, the gas outlets of N combustion chambers are connected through fire transmission grooves, and the gas pipelines include gas main channels and main gas channels. There are N gas branches connected by channels, and each gas branch is connected with a combustion chamber. The main gas channel is provided with a cut-off master valve for opening and closing the main gas channel and a proportional regulating valve for adjusting the gas flow. One gas branch is normally open, and the remaining N-1 gas branches are respectively provided with cut-off branch valves. When in use, the cut-off main valve on the main gas channel is used to control the on-off of the gas supply to the gas stove. During use, according to the adjustment of different firepower g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com