Method and tool for replacing continuous cladding mold for aluminum sheaths of cables

A technology for mold replacement and cable aluminum, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of shortening mold changing time, pollution of sodium hydroxide waste liquid, reducing labor intensity, etc., and achieves shortening mold changing time and ingenious structural design , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

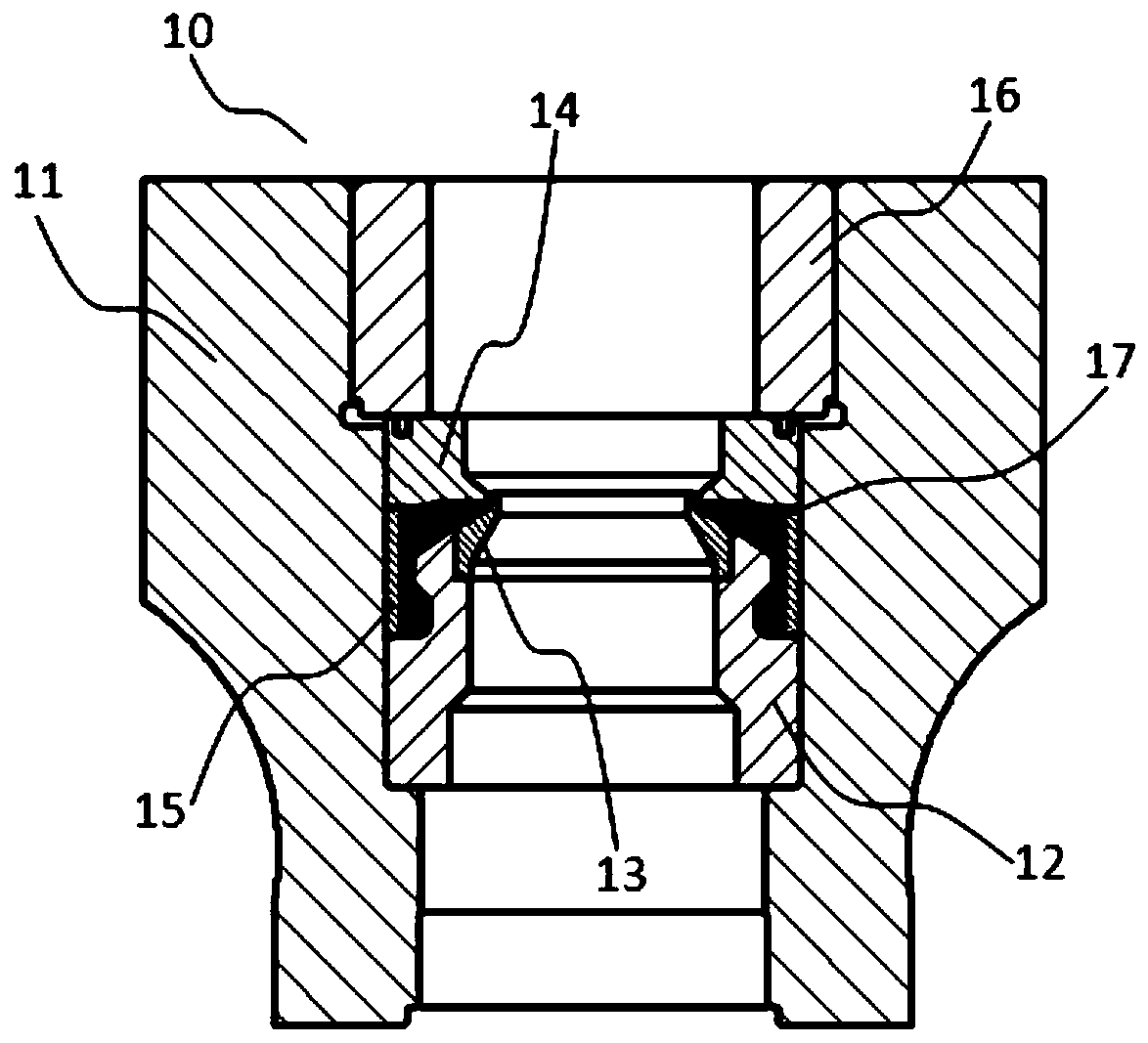

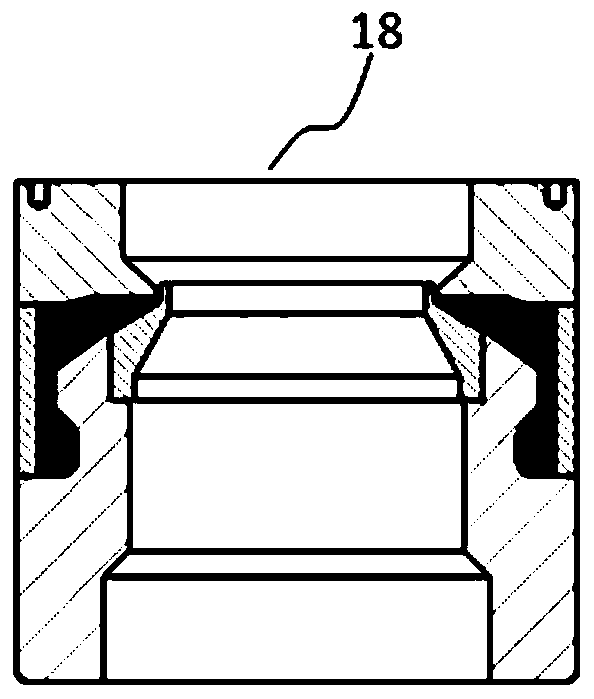

Embodiment 1

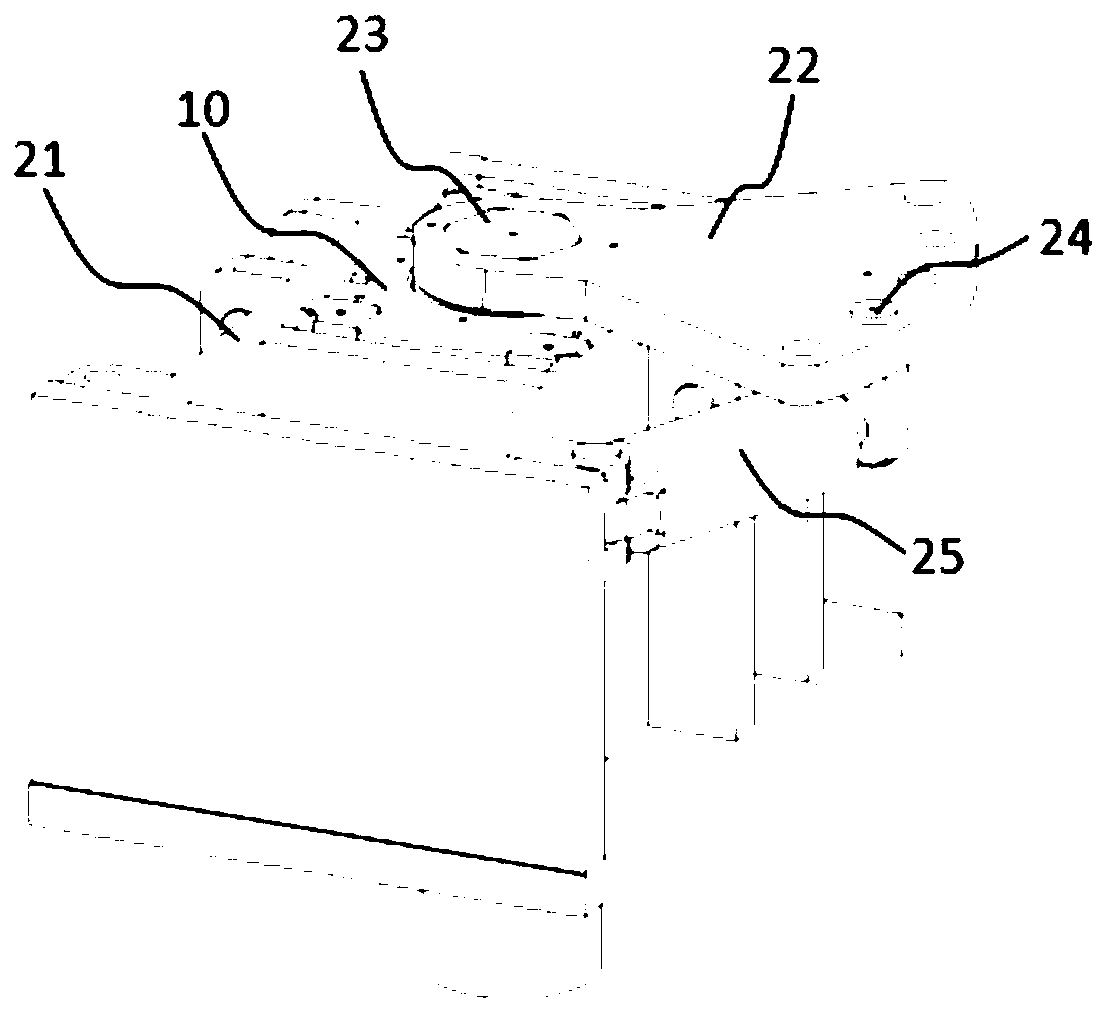

[0036] Such as Figure 3-Figure 4 As shown, a cable aluminum sheath continuous coating mold replacement tool includes a fixed seat 21, a wrench 22, a hexagonal block 23, a pin shaft 24, an upper cover plate 26, a cylindrical pin 27, a push-pull rod 30, a sealing plate 31, Nut 32, push plate 33, and aluminum cutter 34;

[0037] The fixed seat 21 is a square box-shaped part, and the side is equipped with an oil cylinder one 25 for dismounting the lock nut 16. The oil cylinder one 25 is connected to the wrench 22 through the pin shaft 24 positioned at the end of the wrench, and the front end of the wrench 22 is connected to the wrench 22 through six square blocks 23. The lock nut 16 at the top of the cavity 10 is connected, and the lock nut 16 is loosened and locked through the reciprocating movement of the oil cylinder 125;

[0038] The bottom surface of the fixed seat 21 is installed with an oil cylinder two 28 for ejecting the mould, and the upper cover plate 26 is connected ...

Embodiment 2

[0046] Utilize the tool described in embodiment 1 to carry out the replacement method of a kind of cable aluminum sheath continuous coating mould, as Figure 11 shown, including the following steps:

[0047] 1) Pack up the pistons of oil cylinder one 25 and oil cylinder two 28, install the push-pull rod 30 on the piston of oil cylinder two 28, and set the push plate 33 on the push-pull rod 30;

[0048] 2) Put the hot mold cavity 10 with a temperature of 400-500°C into the fixed seat 21, put one end of the hexagonal block 23 into the hexagonal hole of the lock nut 16, and put the wrench 22 into it so that one end is aligned with the hexagonal block 23 connection, the other end is connected with the piston of oil cylinder 25; extend the piston of oil cylinder 25, push the wrench 22 counterclockwise, the pressure of the oil cylinder is 20 MPa, and repeatedly loosen the lock nut 16 until it can be rotated manually until it is disengaged;

[0049] 3) Screw the hole sealing plate 3...

Embodiment 3

[0054] The steps of the replacement method for the continuous coating mold of a cable aluminum sheath described in this embodiment are the same as those in Embodiment 2, the difference is that the pressure of the oil cylinder 1 in the step 2) is 18 MPa, and the step 3 ), the pressure of oil cylinder 2 in step 4) is 12 MPa, the pressure of oil cylinder 2 in step 5) is 11 MPa, and the pressure of oil cylinder 1 in step 6) is 18 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com