Filter element forming machine

A molding machine and filter element technology, applied to cardboard items, etc., can solve the problem of high cost, achieve simple structure, reduce site size and human resources, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

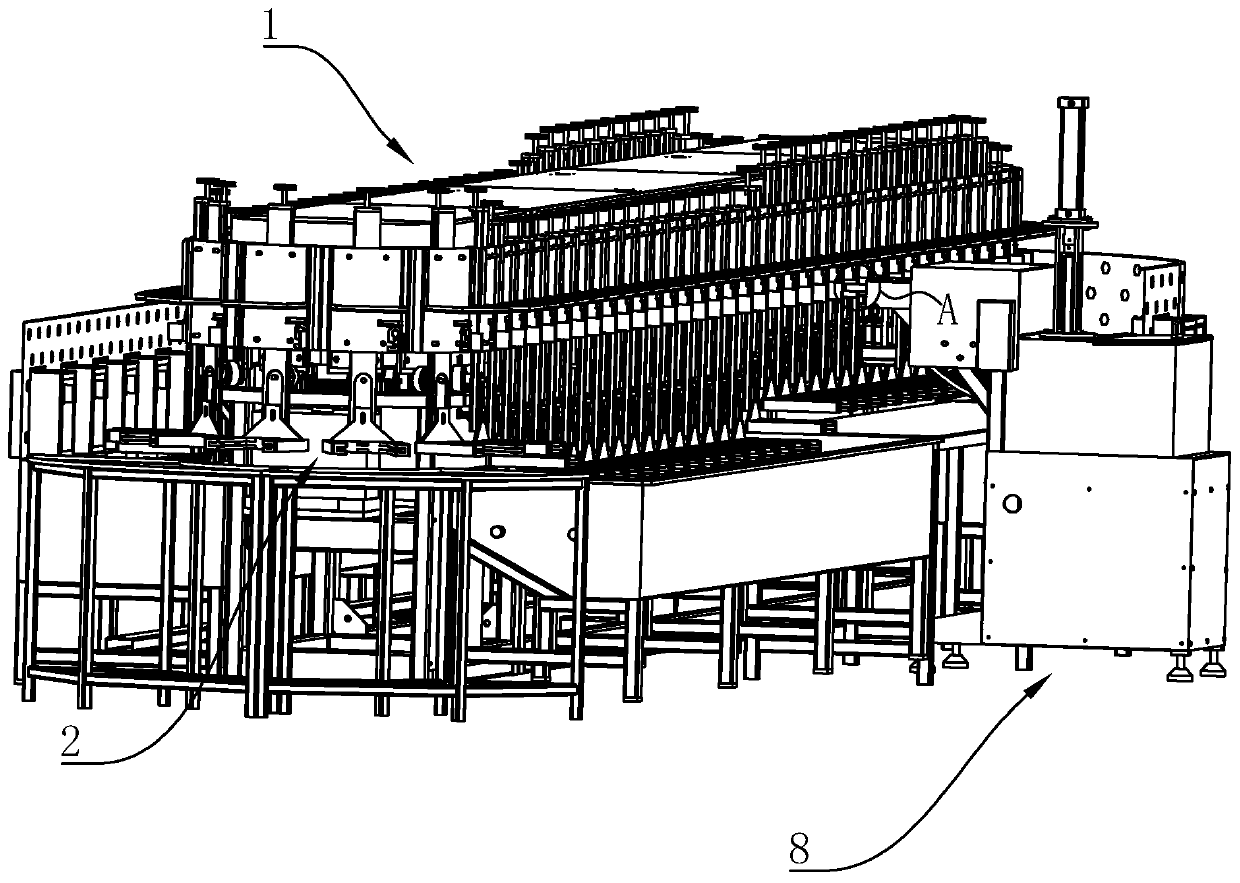

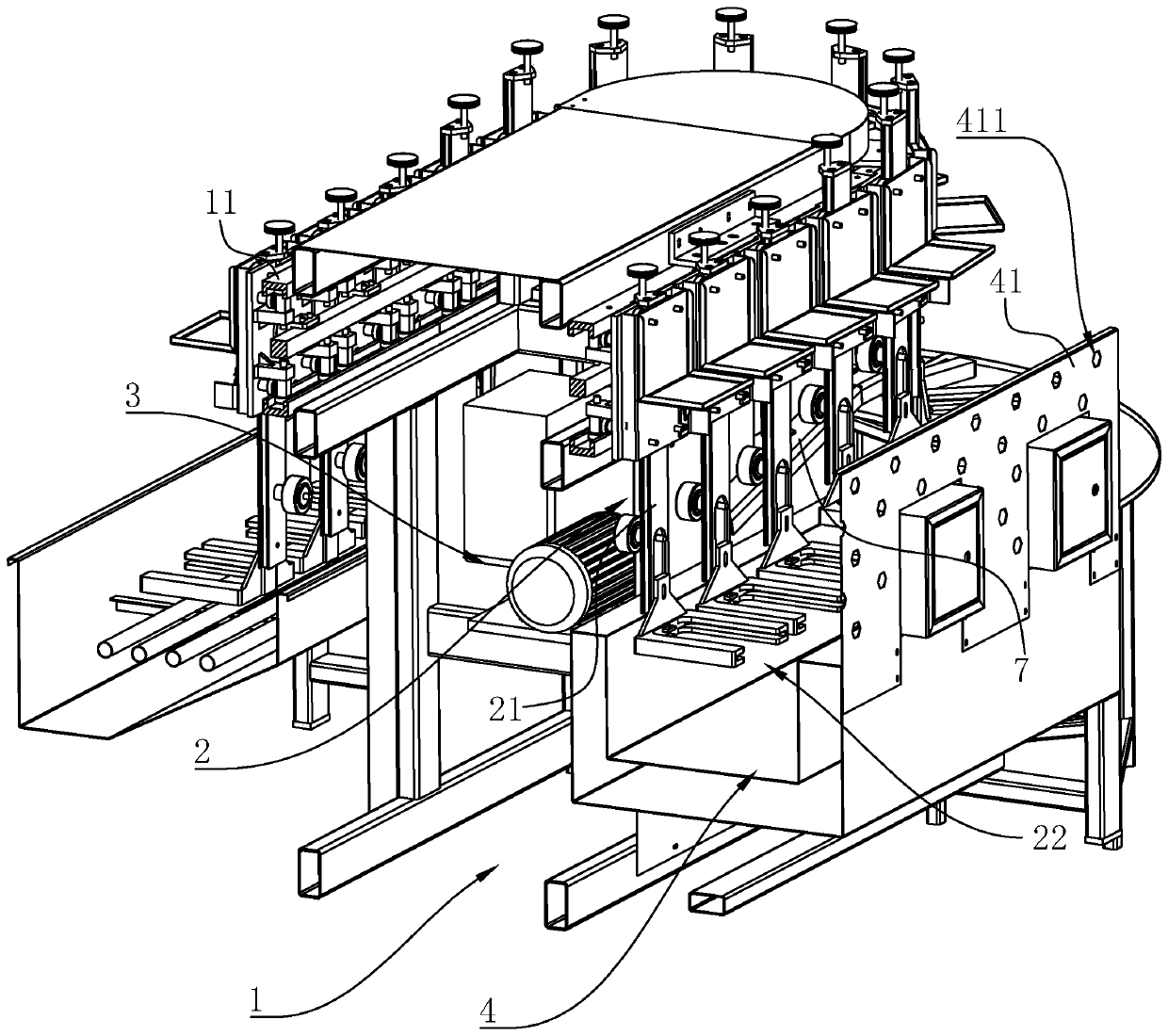

[0049] Embodiment: a kind of filter element forming machine, as figure 1 and figure 2 As shown, it includes a frame 1 and a conveying assembly 2 located on the frame 1; a glue adding machine 8 for adding glue is provided on one side of the frame 1; The power assembly 3; the conveying assembly 2 is composed of a plurality of risers 21 and a shelf 22 arranged at the lower end of the riser 21; the plurality of risers 21 are evenly distributed around the frame 1, so that the conveying assembly 2 is circularly distributed on the frame 1 , under the drive of the power assembly 3 to circulate.

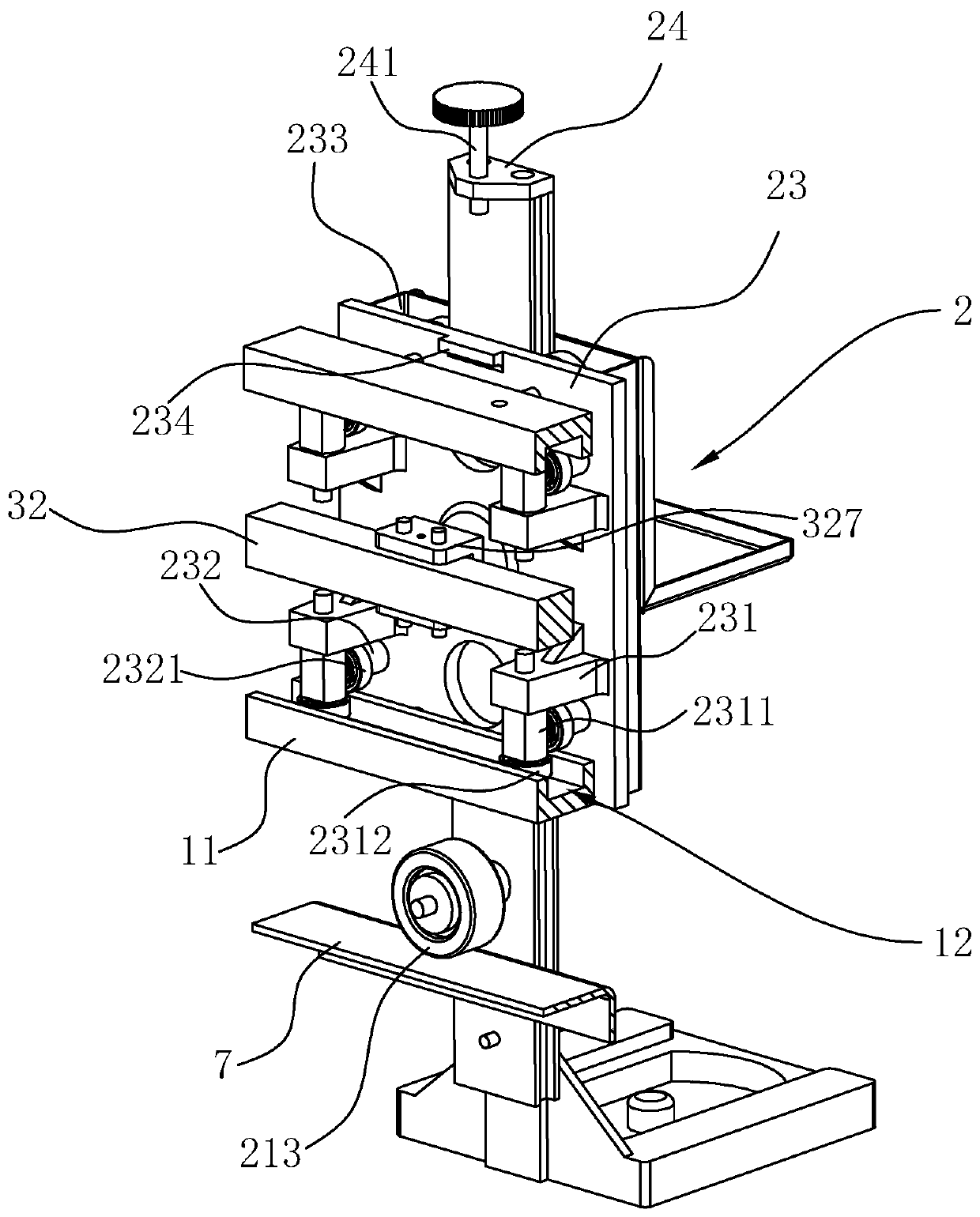

[0050] like figure 2 and image 3 As shown, two layers of slide plates 11 are fixedly connected to the side wall of the frame 1, and each layer of slide plates 11 is composed of two parallel linear parts and two semicircular annular parts, so that each layer of slide plates 11 is arranged in a ring shape. A chute 12 is provided on the surfaces of the sliding plates 11 that are close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com