Copper bar cutting device

A technology for cutting devices and copper rods, which is applied in the direction of shearing devices, feeding devices, and accessories of shearing machines, etc., which can solve the problems of inconvenient movement of cutting tools and fixtures, rigid cutting machines, and insufficient easy operation, etc., and achieve relief. Effects of labor intensity and human resources, reducing equipment loss, and increasing environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

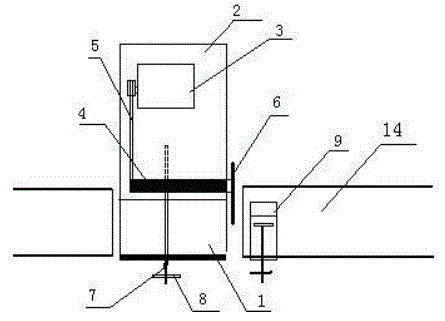

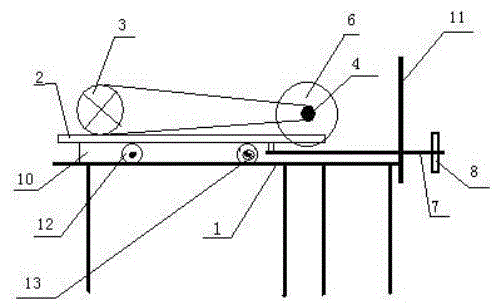

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] A copper rod cutting device, comprising a bracket 1, a baffle plate 11, a threaded rocker 7, a ram, a hand wheel 8, a transmission frame, a manual fixing device 9 and a cutting machine, the ram includes a pillow plate 2, a pulley shaft 13 , pulley 12 and chute 10, described pulley shaft 13 is installed under pillow plate 2, and pulley 12 is installed on the pulley shaft 13, and described pulley 12 is installed in the chute 10, and described ram is installed on the support 1, Described cutting machine is installed on the pillow board 2; Described cutting machine comprises motor 3, belt 5 and cutter 6, and the shaft of motor 3 is connected with the drive shaft 4 of belt 5 and cutter 6, and described cutter 6 is arranged on the ram On the right side, the outer diameter of the tool 6 exceeds the front edge of the ram, the baffle 11 is arranged on the frame, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com