Cloth lamination device and method

A composite device and fabric technology, applied in the field of mechanical processing, can solve the problems of fabric strength damage, cumbersome process, fluff and other problems, and achieve the effects of not easy to run down, simple process and good composite quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

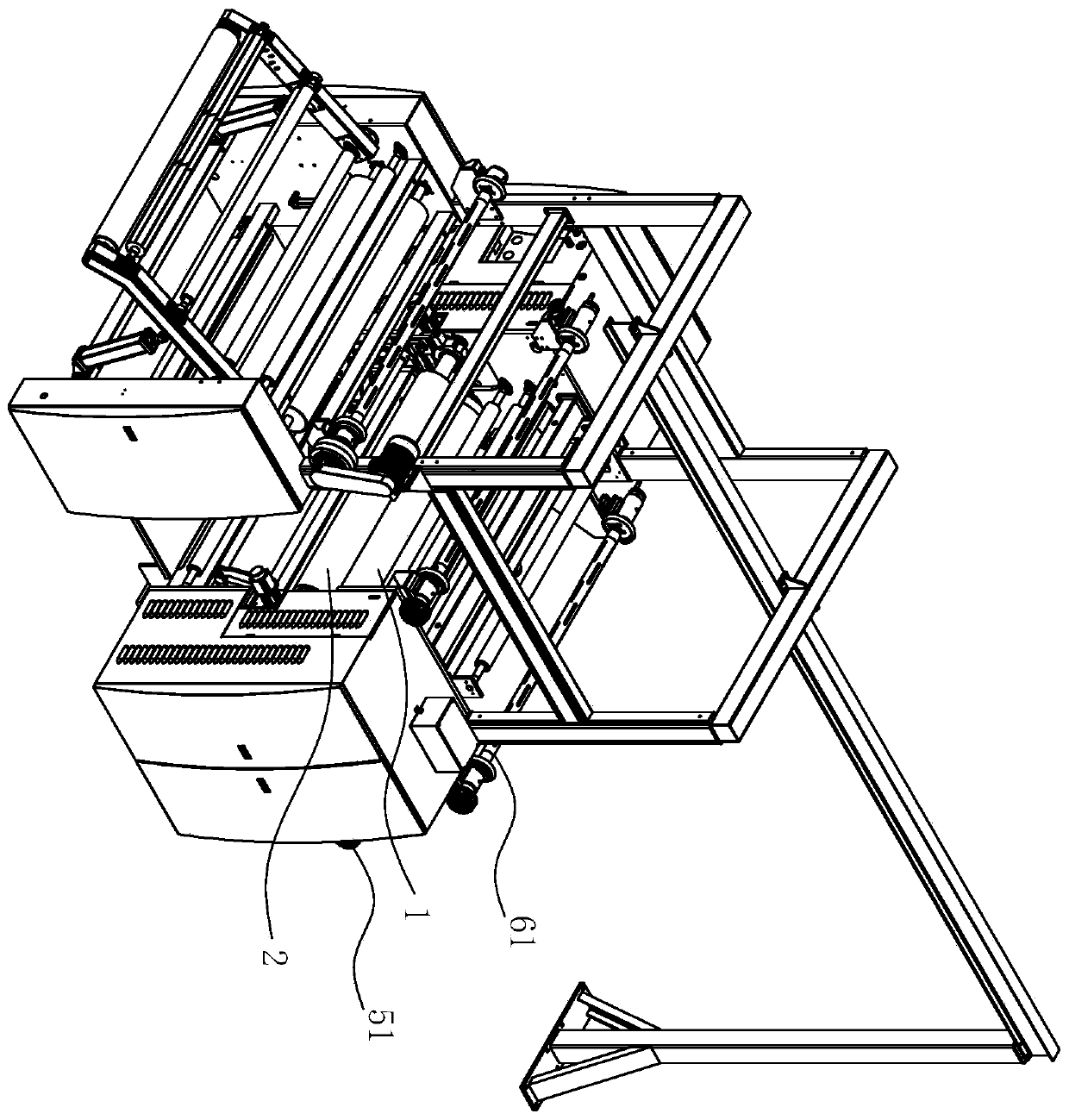

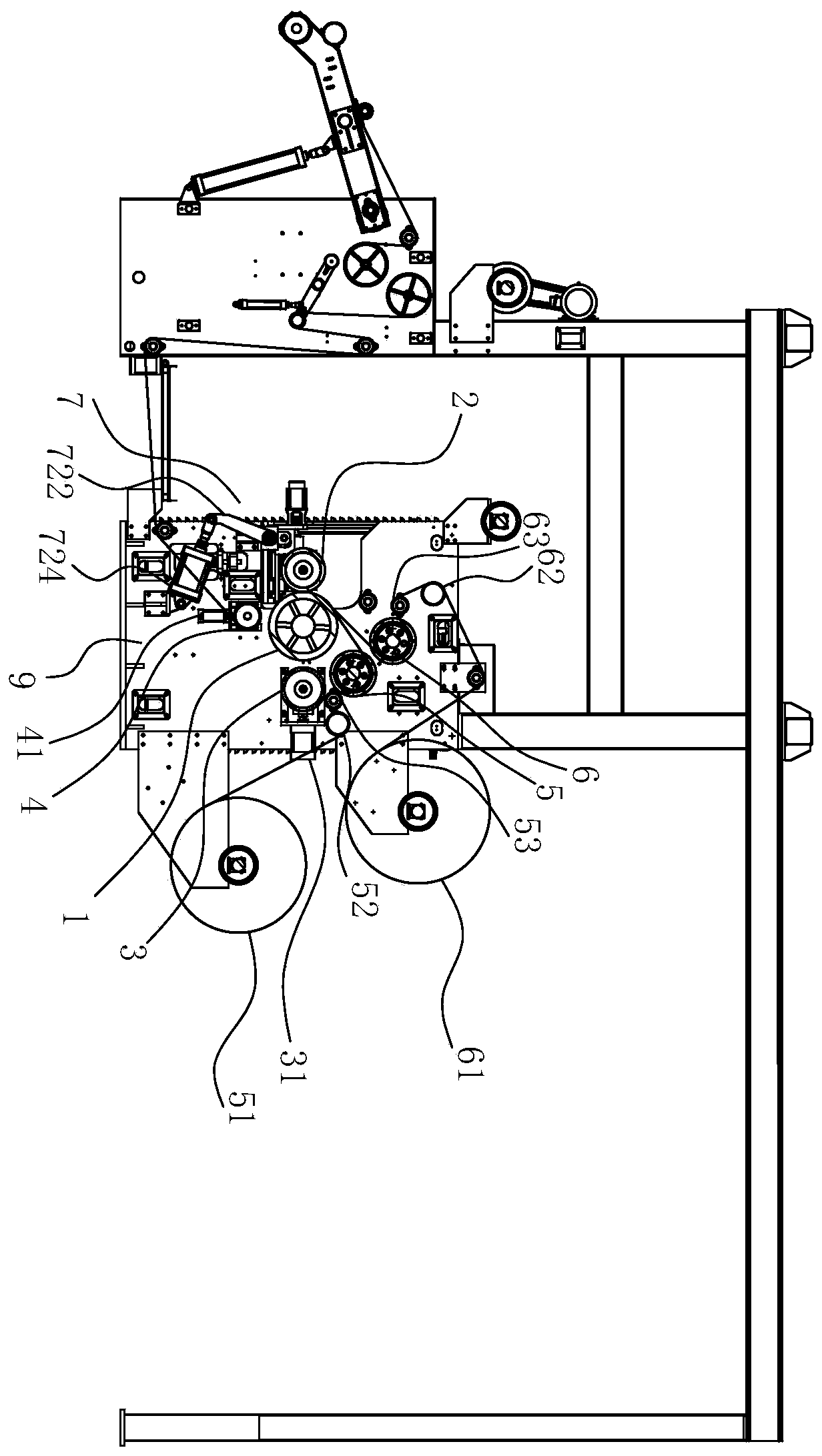

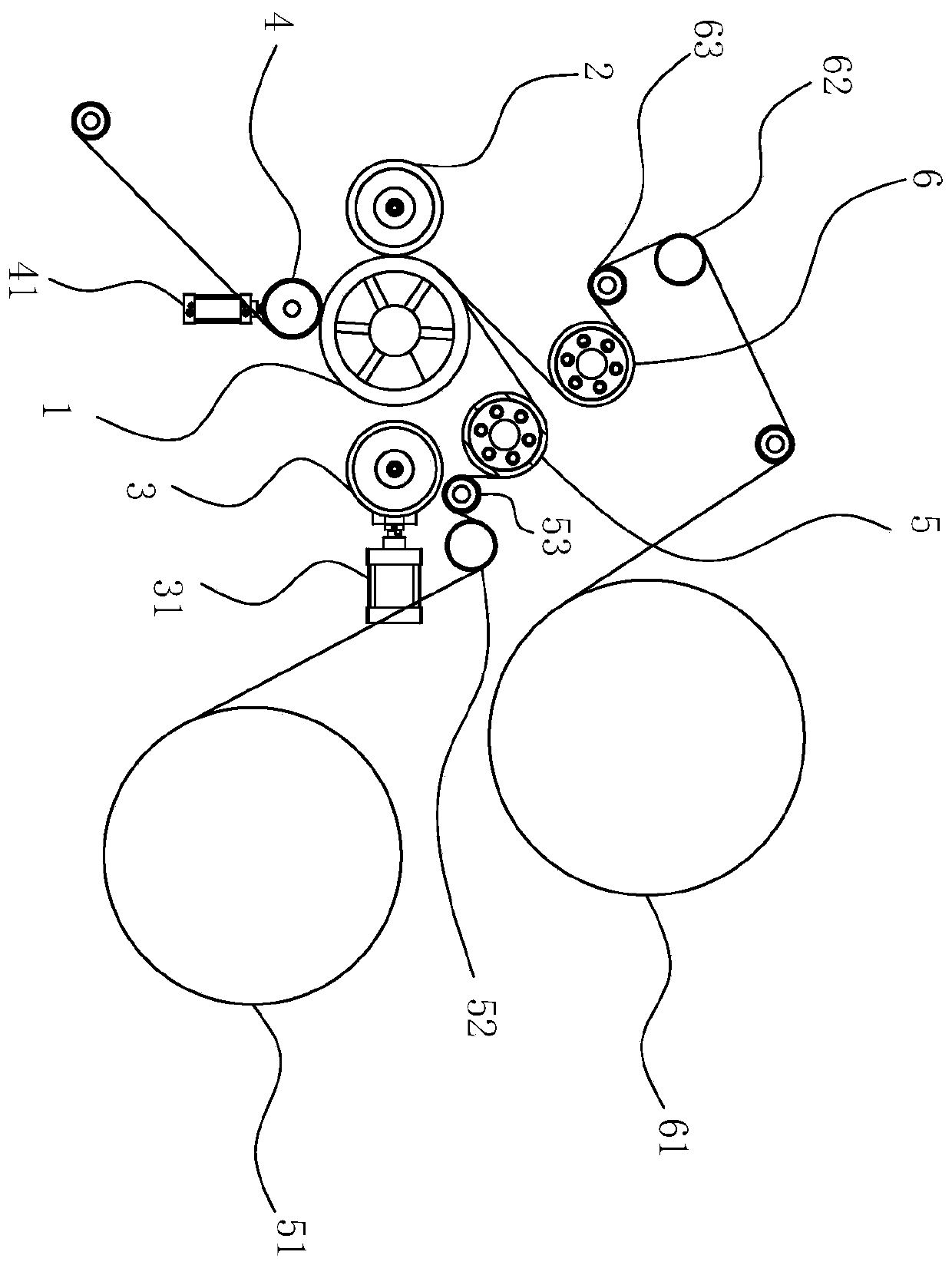

[0032] In conjunction with the accompanying drawings, the present invention proposes a cloth compounding device according to the deficiencies of the prior art, which is used to compound the base cloth and the face cloth according to the corrugated or tooth-shaped printing pattern so that a velvet storage space is formed between the base cloth and the face cloth The opposite surfaces of the base cloth and the face cloth are compounded with a hot-melt film in advance, including a frame 9, a base cloth heat roller 5 that is rotatably arranged on the frame 9 and is parallel to each other, a face cloth heat roll 6, a flower roll 1, Pressure roller 2, support roller 3, driving part, installation device 7, auxiliary roller 4, third air cylinder 41, bottom cloth raw material roller 51, face cloth raw material roller 61, bottom cloth expanding roller 52, surface cloth expanding roller 62, The first guide wheel 53, the second guide wheel 63, the bottom is arranged on the base cloth raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com