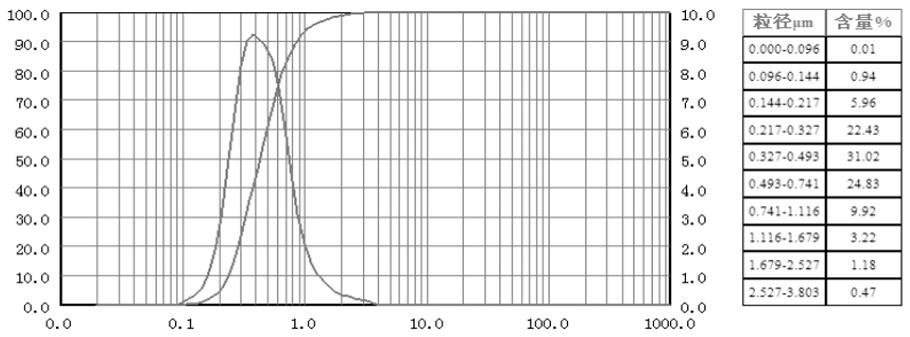

Acrylic acid emulsion with wide particle size distribution and preparation method thereof

A technology of acrylic emulsion and acrylic acid, applied in the direction of coating, can solve the problems of complex process realization, and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method comprises the following steps:

[0026] (1) Add 35% of the total water and 50% of the total emulsifier into the pre-emulsification tank, add butyl acrylate, styrene, acrylic acid and acrylonitrile monomers under stirring conditions, and react to obtain a pre-emulsion;

[0027] (2) Release 5% of the total amount of pre-emulsion into the seed emulsion tank, and add sodium bicarbonate, 30% of the total amount of initiator, 50% of emulsifier and 60% of water into the seed emulsion tank ; The temperature is raised to 80°C-85°C for polymerization; preferably, the temperature is raised to 80°C for 30 minutes.

[0028] (3) Add acrylamide and 50% of the total amount of initiator to the pre-emulsion tank, and stir evenly; add liquid from the pre-emulsion tank to the seed emulsion tank, and at the same time, continuously pour the liquid in the seed emulsion tank into the pre-emulsion tank Medium pumping, control the pumping speed to be lower than the droppi...

Embodiment 1

[0039] Add 29.8 kg of water and 1 kg of emulsifier TR / 2030-S into the 100 L pre-emulsification tank, start stirring and add 40 kg of butyl acrylate, 25 kg of styrene, 2 kg of acrylic acid, and 10 kg of acrylonitrile under stirring. After stirring for 20 minutes, 5.4 kg of the pre-emulsion was metered out to a 200 L seed emulsion polymerization kettle, and 0.3 kg of initiator ammonium persulfate, 0.6 kg of emulsifier, 51 kg of water and 0.2 kg of water were added to the 200 L of seed emulsion polymerization kettle kg of sodium bicarbonate, and the temperature was raised to 80°C for 30 minutes of polymerization. Add 2 kg of acrylamide and 0.5 kg of ammonium persulfate to the 100 L pre-emulsification tank and stir evenly, then start to add dropwise to the polymerization tank, and at the same time pump the liquid in the polymerization tank into the pre-emulsification tank continuously, and the speed is controlled at the dropping speed Half of the amount, the dropwise addition time...

Embodiment 2

[0041]Add 33.3 kg of water and 1.5 kg of emulsifier A6820 into the 100 L pre-emulsification tank, start stirring and add 40 kg of butyl acrylate, 30 kg of styrene, 3 kg of acrylic acid, and 12 kg of acrylonitrile under stirring. After stirring for 20 minutes, 6 kg of the pre-emulsion was metered out to a 200 L seed emulsion polymerization kettle, and 0.36 kg of initiator ammonium persulfate, 1.5 kg of emulsifier, 57 kg of water and 0.3 kg of water were added to the 200 L of seed emulsion polymerization kettle. kg of sodium bicarbonate, and the temperature was raised to 80°C for 30 minutes of polymerization. Add 3 kg of acrylamide and 0.6 kg of ammonium persulfate to the 100 L pre-emulsification tank and stir evenly, then start to add dropwise to the polymerization tank, and at the same time, pump the liquid in the polymerization tank into the pre-emulsification tank continuously, and the speed is controlled at the dropping speed Half of the solution, control the dropping time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap