A Method for Improving the Lamination Cavity of Mixed Press Plate

A technology of plate pressing and voiding, applied in the direction of multilayer circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of board scrapping, achieve the effect of solving scrapping, improving scrapping, and improving filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

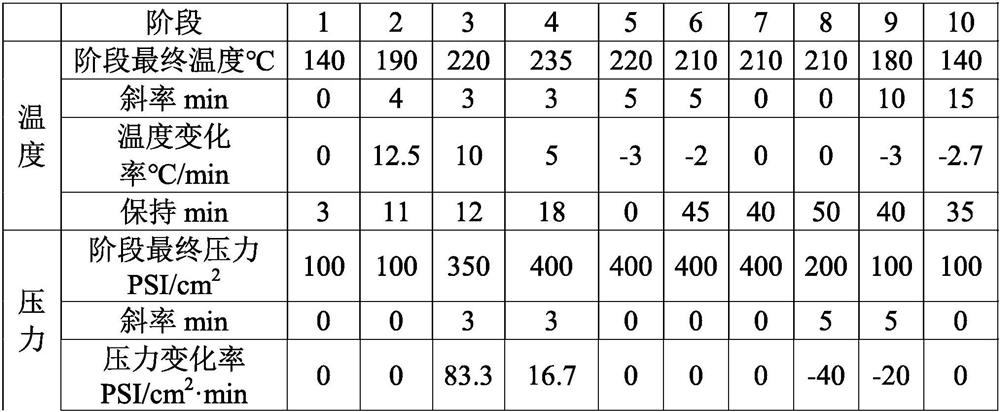

Embodiment 1

[0020] This embodiment provides a method for preparing a mixed pressure board, especially a method for improving the pressure cavity of a mixed pressure board during the production of a mixed pressure board. The mixed laminated board of this embodiment is made of a pre-laminated structure formed by 2 eight-layer sub-boards and 3 inner-layer core boards, after lamination, outer-layer drilling and other post-processes. In the sub-board, the adhesive layer in the inner core board and the adhesive sheet for lamination are prepregs of model TU883; the adhesive layer in the other inner core board and the adhesive sheet used for lamination with the sub-board It is a prepreg of model TU865; the thickness of the finished board is 3.15±0.25mm, the minimum hole diameter of the sub-board is 0.175mm, and the minimum distance from the inner hole to the copper is 0.175mm.

[0021] Specifically include the following steps:

[0022] 1. Processing of inner core board

Embodiment 2

[0051] This embodiment provides a method for preparing a mixed pressure board. The stacked structure of the mixed laminated board in this embodiment is consistent with that of the mixed laminated board in Example 1. The pre-laminated structure formed by 2 eight-layer sub-boards and 3 inner-layer core boards is laminated, outer-layer drilled, etc. Made in post process. In the sub-board, the adhesive layer in the inner core board and the adhesive sheet for lamination are prepregs of model TU883; the adhesive layer in the other inner core board and the adhesive sheet used for lamination with the sub-board It is a prepreg of model TU865; the thickness of the finished board is 3.15±0.25mm, the minimum hole diameter of the sub-board is 0.175mm, and the minimum distance from the inner hole to the copper is 0.175mm. The specific steps of preparing the mixed press board in this example are basically the same as those in Example 1, the difference lies in the control of temperature and ...

Embodiment 3

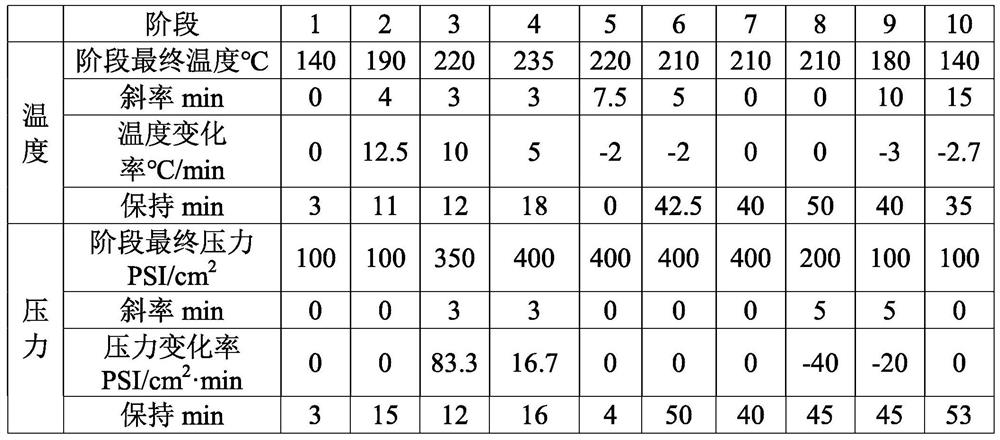

[0055] This embodiment provides a method for preparing a mixed pressure board. The stacked structure of the mixed laminated board in this embodiment is consistent with that of the mixed laminated board in Example 1. The pre-laminated structure formed by 2 eight-layer sub-boards and 3 inner-layer core boards is laminated, outer-layer drilled, etc. Made in post process. In the sub-board, the adhesive layer in the inner core board and the adhesive sheet for lamination are prepregs of model TU883; the adhesive layer in the other inner core board and the adhesive sheet used for lamination with the sub-board It is a prepreg of model TU865; the thickness of the finished board is 3.15±0.25mm, the minimum hole diameter of the sub-board is 0.175mm, and the minimum distance from the inner hole to the copper is 0.175mm. The specific steps of preparing the mixed press board in this example are basically the same as those in Example 1, the difference lies in the control of temperature and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com