Heat dissipation device for mechanical and electrical equipment

A technology for heat dissipation devices and electromechanical equipment, which is applied to structural parts of electrical equipment, electrical components, and decoration through conduction and heat transfer. problems, to achieve a good cooling environment, save installation space, and improve cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

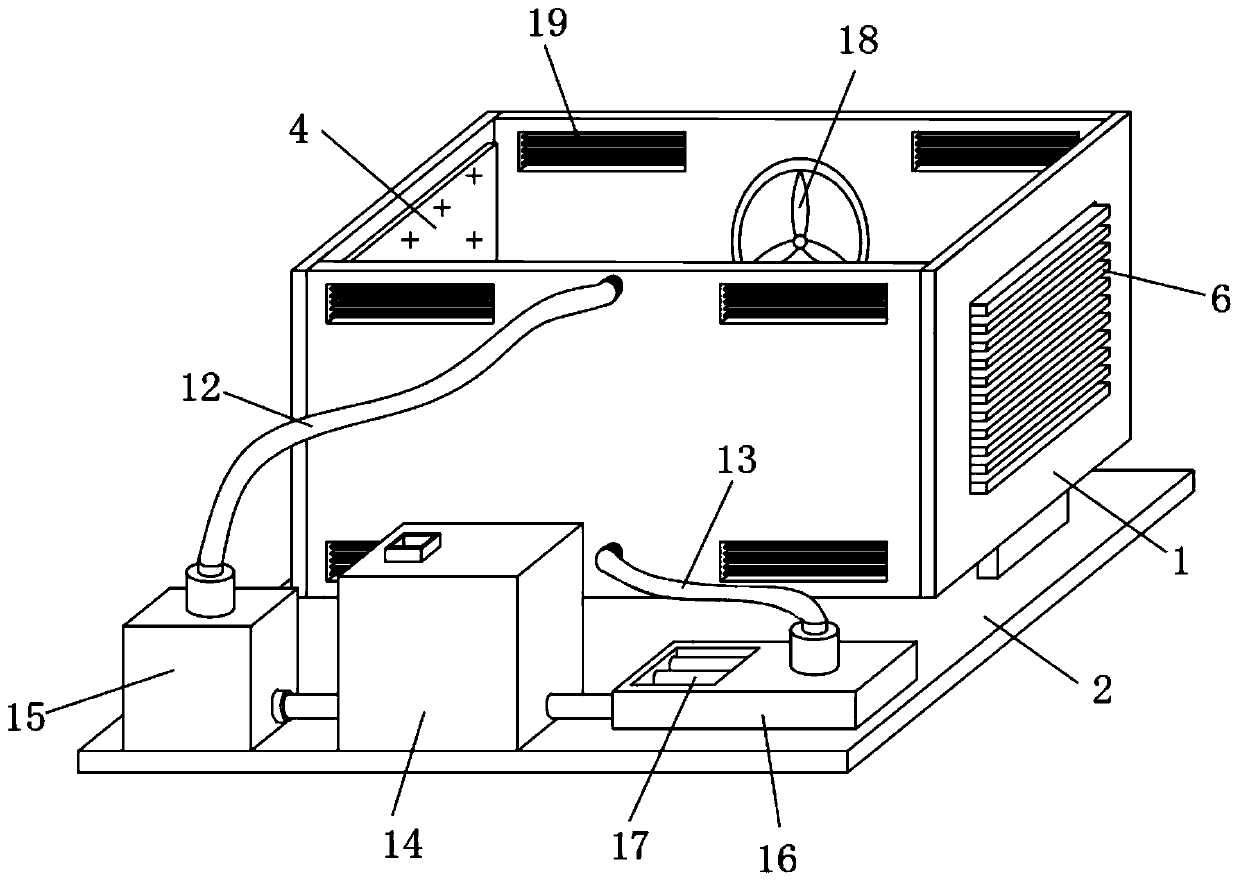

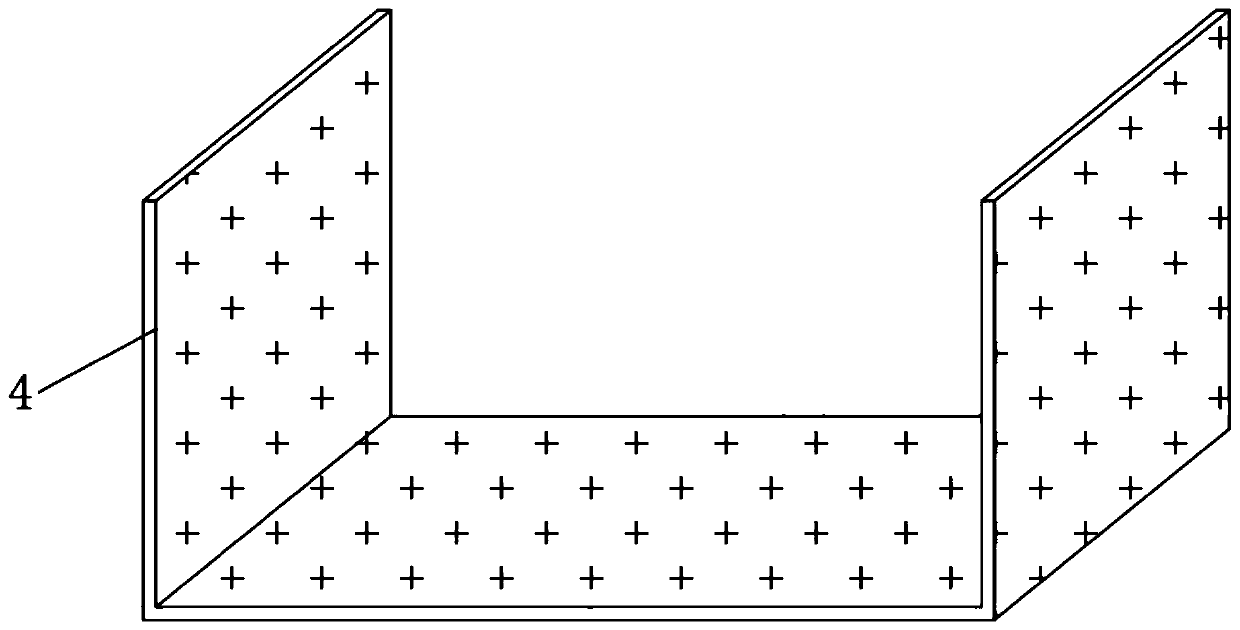

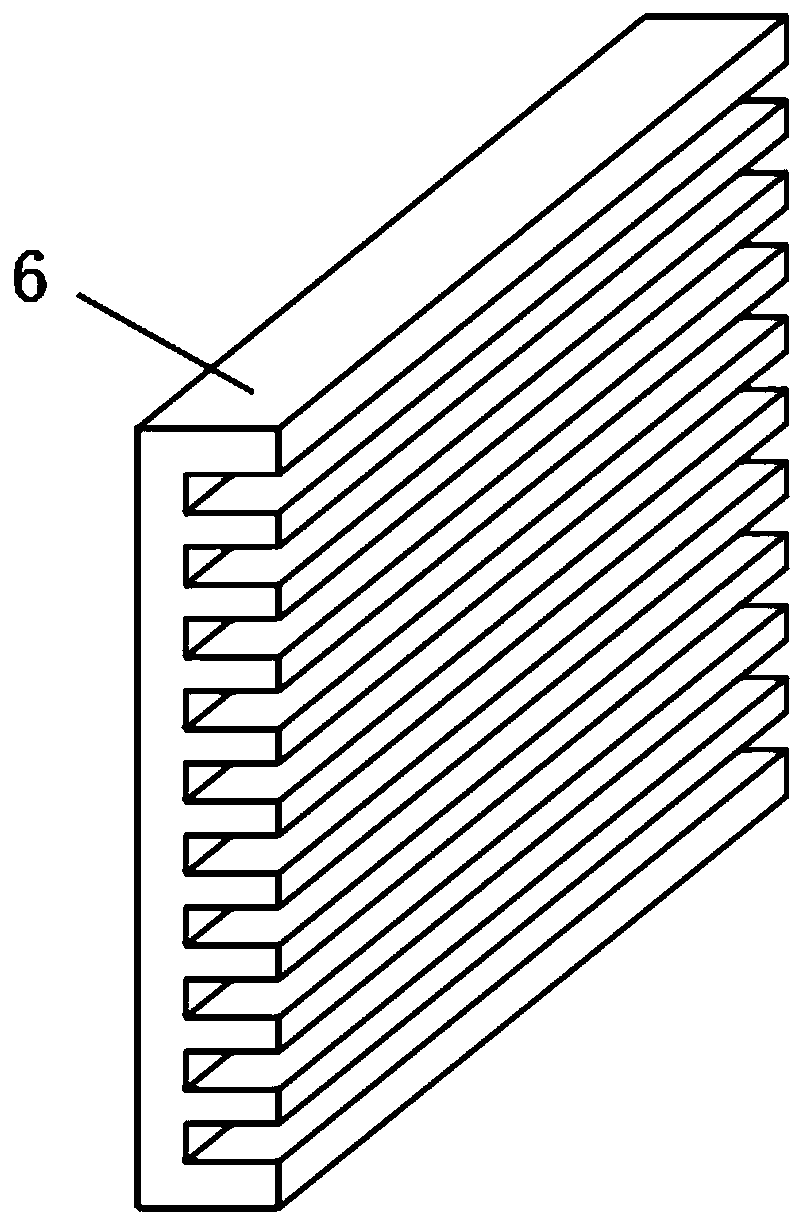

[0032] see Figure 1-3 , a heat dissipation device for electromechanical equipment, comprising a heat dissipation box 1 and a base 2 fixedly connected to the bottom of the heat dissipation box 1, the middle part of the lower end of the heat dissipation box 1 is fixedly connected to the base 2 through a support seat 3, and can be placed on the heat dissipation box 1 as required Install support plates on both sides of the bottom of the bottom respectively, which is conducive to improving the stability of the heat dissipation box 1. A U-shaped heat conducting plate 4 is sleeved inside the heat dissipation box 1, and the outer end side wall of the U-shaped heat conducting plate 4 is sealed with the heat dissipation box 1. Connected, the side walls on both sides of the inner bottom of the heat dissipation box 1 are provided with a plurality of strip-shaped heat dissipation chambers, and the strip-shaped heat dissipation chambers are embedded with heat dissipation strips 5, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com