Metal semi-autogenous-grinding ball mill lining plate

A ball mill liner, semi-autogenous grinding technology, applied in the direction of sounding equipment, grain processing, instruments, etc., can solve the problems of short service life, high cost, large power consumption, etc., to prolong the service life of equipment and improve the efficiency of installation work , Improve the effect of equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

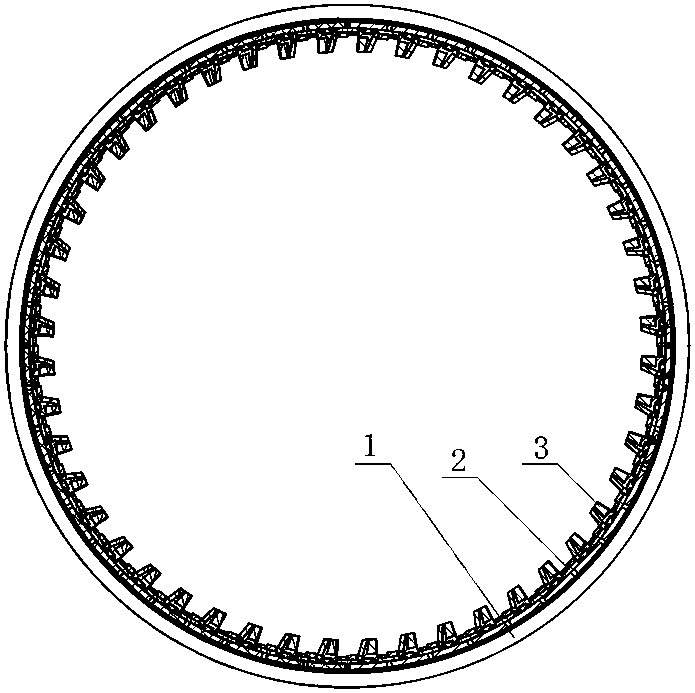

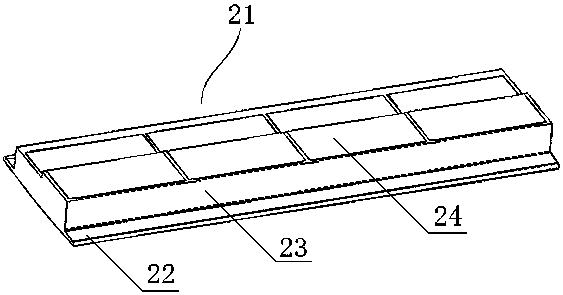

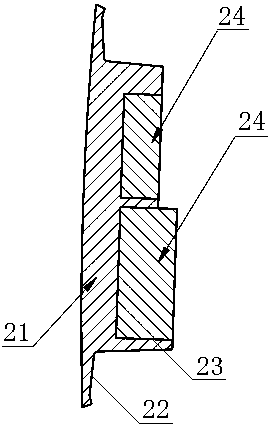

[0021] like figure 1 , 2 , a metal ore semi-autogenous grinding ball mill lining plate shown in 3, 4, and 5 is composed of a number of composite cylinder plates 2 that are evenly distributed on the circumference of the semi-autogenous grinding cylinder 1 and installed in the semi-autogenous grinding cylinder 1, and Composite lifting strip 3 installed between every two composite tube plates 2; the composite tube plate 2 includes a rubber tube plate body 21 with several slots, and the tube plate body 21 is arc-shaped conforming to the circumference of the semi-autogenous grinding cylinder , there are two mounting ears 22 on both sides of the tube plate body 21, and two rows of socket bodies 23 higher than the mounting ears in the middle of the tube plate body 21, wherein one row of socket bodies is higher than the other row of socket bodies to form a step , each row of inserting grooves is provided with several inserting grooves, and wear-resistant alloy blocks 24 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com