Automatic air-purging type oil spill prevention device and control method thereof

A control method and gas-driven technology, which is applied in transportation and packaging, ship construction, naval ships, etc., can solve problems such as detachment of refueling hoses of oil trucks, environmental pollution accidents, energy loss, etc., and achieve reduction of oil and gas content and versatility Practicality, quick disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

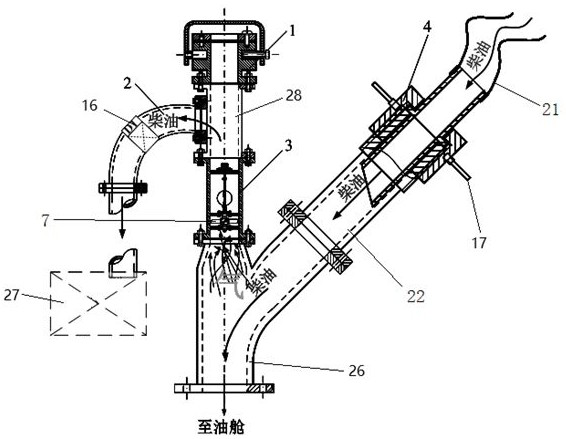

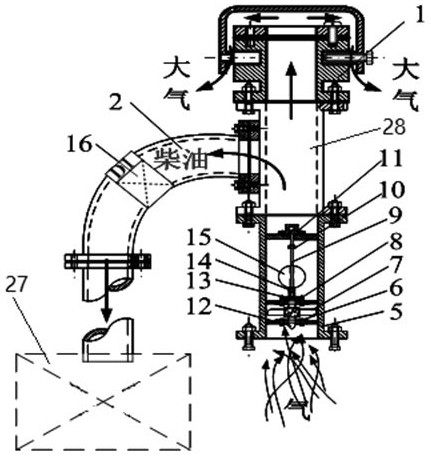

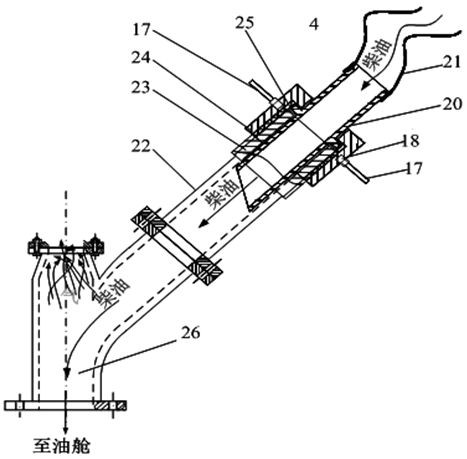

[0049] Please see attached figure 1 to attach image 3 , an automatic air-driving type oil spill prevention device, comprising a vent 1, an oil-gas separation and ventilation device 3, a quick interface 4, a refueling pipe 22 and an oil inlet pipe 26; one end of the refueling pipe 22 is connected to a refueling soft The pipe 21 and the quick interface 4 not only improve the efficiency of connection and disassembly, but also play the role of sealing, anti-overflow, and anti-jumping pipes, thereby completely avoiding the occurrence of oil pollution accidents caused by pipe jumping; the oil inlet pipe 26 is one end Forked Y-shaped structure, the other end of the oil filling pipe 22 is connected to the oil tank through the oil inlet pipe 26; the oil and gas separation and ventilation device 3 is connected to the bifurcated end of the oil inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com