Closed crankcase ventilation system for engine and vehicle

A crankcase ventilation and engine technology, which is applied in the direction of crankcase ventilation, engine components, machines/engines, etc., can solve the problems of parts pollution, high separation effect of oil and gas separator, etc., and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

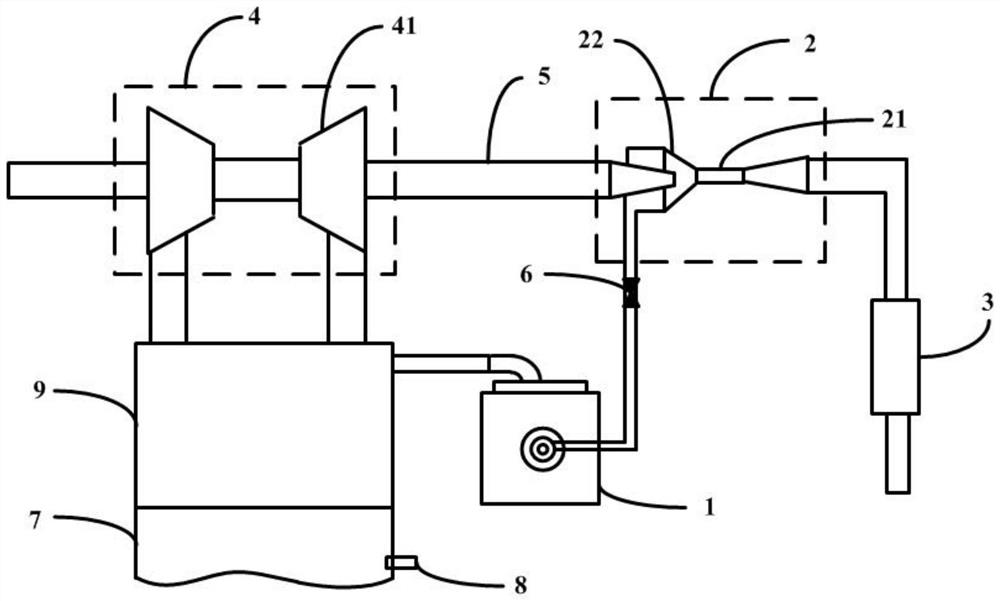

[0027] figure 1 A schematic structural diagram of a closed crankcase ventilation system for an engine according to an embodiment of the present invention is shown. Such as figure 1 As shown, the closed crankcase ventilation system includes an oil-air separator 1 and a negative pressure guiding device 2 . The oil-gas separator 1 is used for separating the high-temperature oil gas entering the crankcase after combustion in the cylinder of the engine 9 or the mixed oil-gas mixed with the high-temperature oil gas and fresh air. The negative pressure guiding device 2 is respectively connected with the gas outlet end of the oil-gas separator 1 and the inlet port of the engine aftertreatment system 3, and is used to guide the exhaust gas separated by the oil-gas separator 1 to the engine aftertreatment system 3 to utilize the engine The aftertreatment system 3 reprocesses the exhaust gas and discharges the reprocessed exhaust gas into the air outside the vehicle.

[0028] Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com