Light environment-friendly paperboard for making packing box and V-groove machine for paperboard processing

A packaging box, environmentally friendly technology, applied in the field of cardboard manufacturing and processing, can solve the problems of V-groove machine cutting right-angle grooves, cardboard deviation, gray cardboard weight and other problems, to ensure reliability and stability, prevent cardboard from lifting , the effect of perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0060] Example.

[0061] see Figure 1 to Figure 17 .

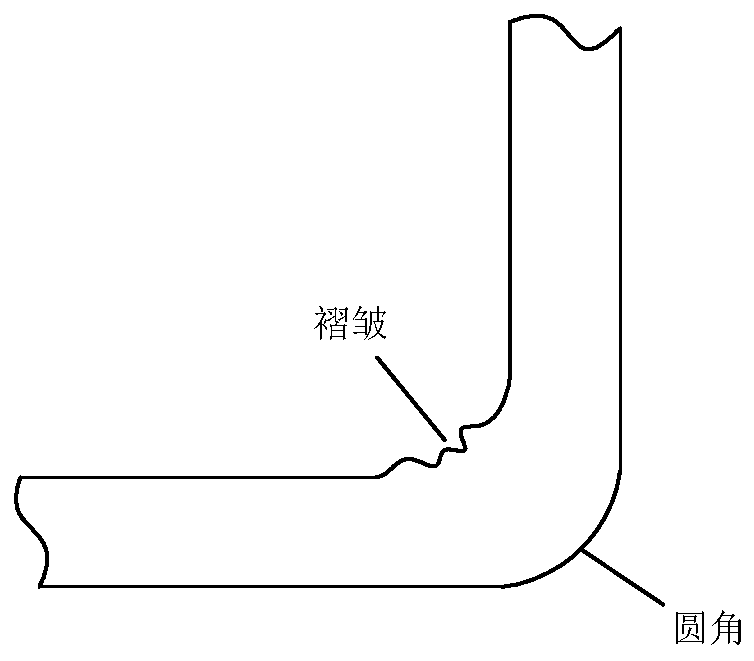

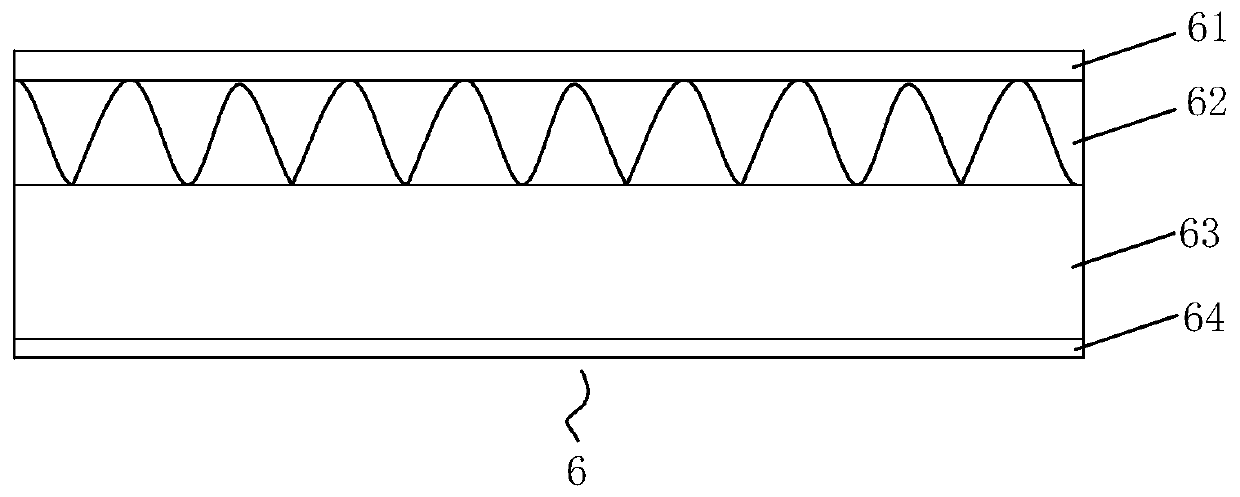

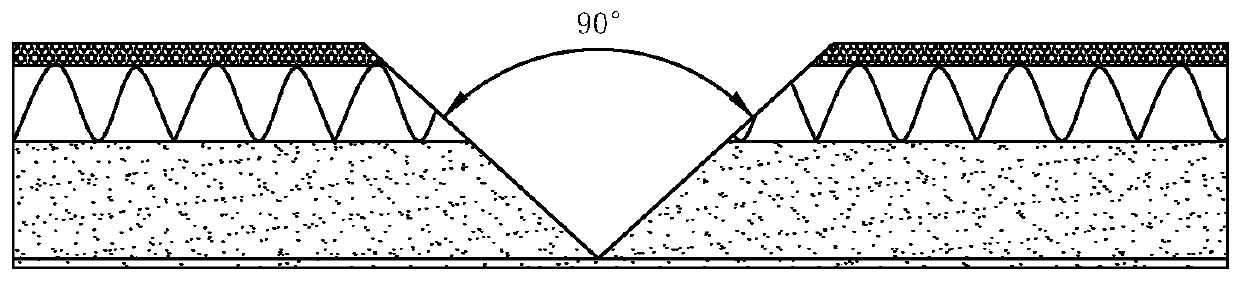

[0062] In this embodiment, the lightweight environment-friendly cardboard 6 used to make the packaging box is a four-layer structure, see figure 2 , the four-layer structure from top to bottom is an inner glued paper layer 61, a corrugated paper layer 62, a gray cardboard layer 63 and an outer glued paper layer 64. Inner gummed paper layer 61 is used as the inner packaging surface of packing box, and outer gummed paper layer 64 is used as the outer packaging surface of packaging box, and the thickness of inner gummed paper layer 61 is greater than the thickness of outer gummed paper layer 64; Inner gummed paper layer 61 selects 200g double for use Adhesive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com