A method for chemically preparing active micronano magnesium hydroxide flame retardant

A magnesium hydroxide, micro-nano technology, applied in magnesium hydroxide and other directions, can solve the problems of many by-products, complex processes, and many impurities, and achieve the effects of improving compatibility and dispersibility, and excellent quantum effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

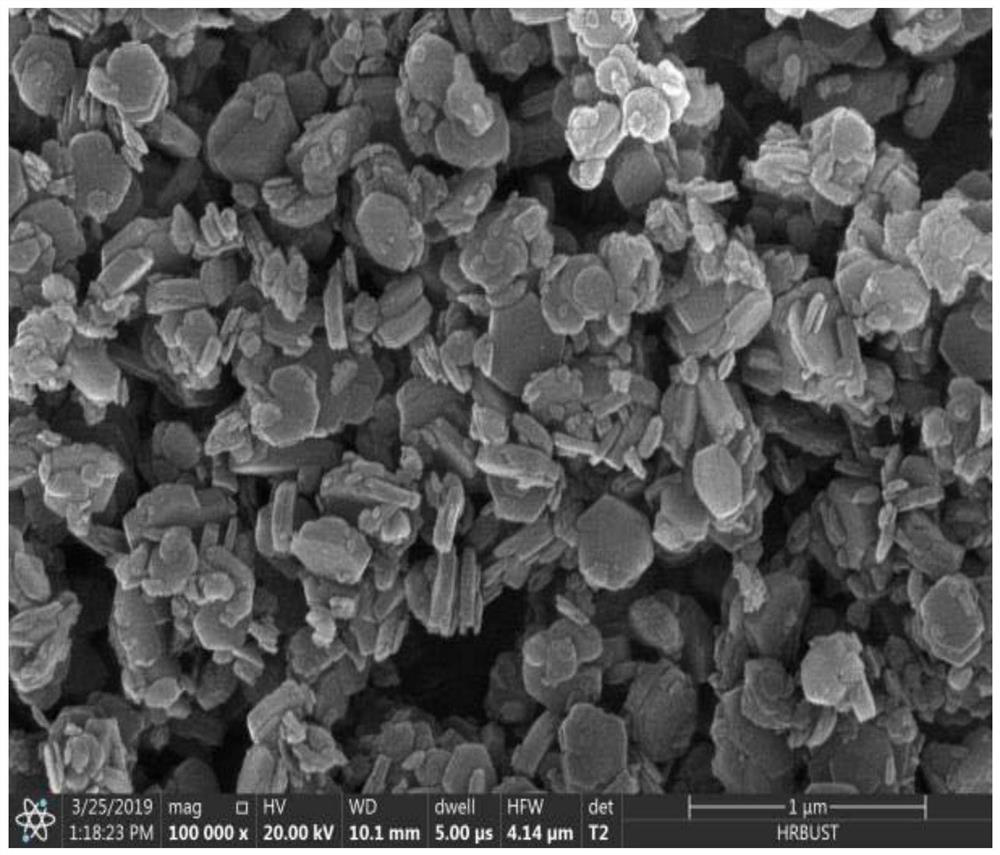

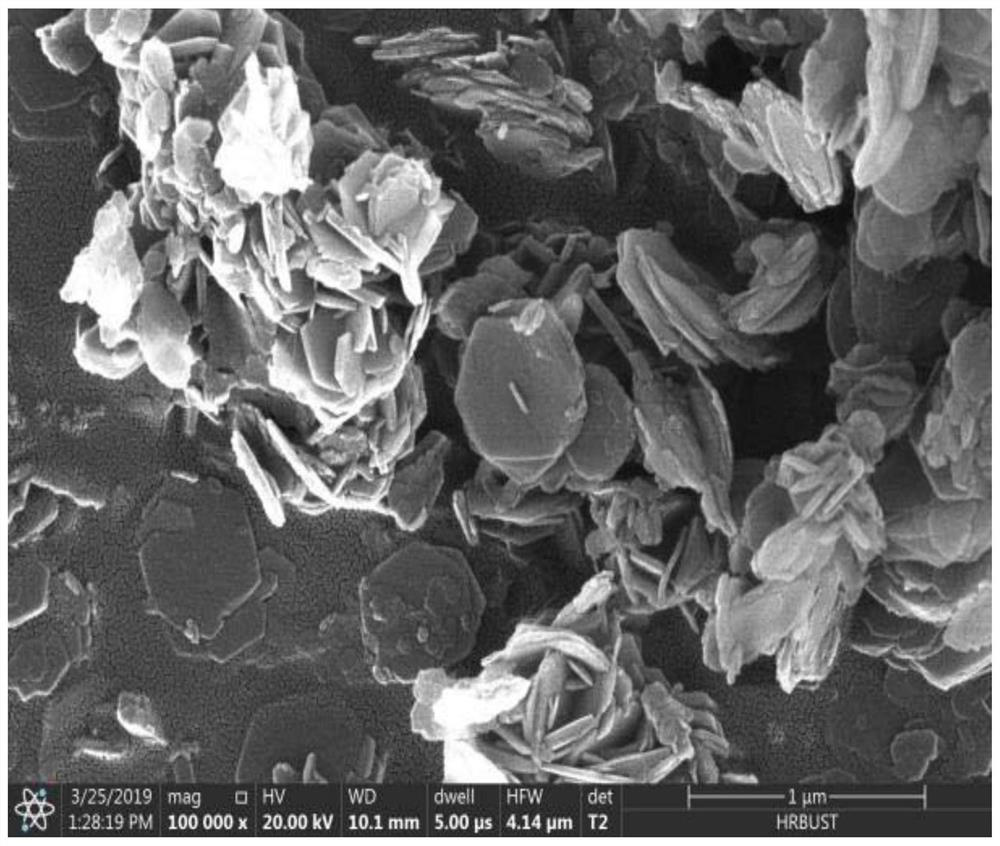

Image

Examples

Embodiment 1

[0042] A method for chemically preparing active micro-nano magnesium hydroxide flame retardant, the method comprises the following steps:

[0043] take MgCO 3 The magnesite tailings with a content of 58% are used as raw materials. The raw materials are removed by primary manual beneficiation to remove impurities such as gangue, and the sorted raw materials are crushed into particles ranging from 10 to 20 mm. Water magnesium chloride is mixed evenly, heated at a rate of 5°C / min in a kiln, and calcined at 700°C for 1 hour to obtain active light-burned magnesium, which is sieved with 60 mesh to remove uncombined and decomposed CaCO 3 As well as impurities such as silicate, further purification;

[0044] Grind the active light-burned magnesium to 200 mesh, mix the active light-burned magnesium and water in a weight ratio of 1:2 in a stirring tank, and stir at 80 rpm for 1 h to obtain a magnesium hydroxide slurry;

[0045]Add ethylene glycol as a dispersant to the magnesium hydro...

Embodiment 2

[0049] A method for chemically preparing active micro-nano magnesium hydroxide flame retardant, the method comprises the following steps:

[0050] take MgCO 3 The magnesite tailings with a content of 68% are used as the raw material. The raw materials are subjected to primary manual beneficiation to remove impurities such as gangue, and the sorted raw materials are crushed into particles ranging from 10 to 20 mm. Water magnesium chloride is mixed, heated at a rate of 5°C / min in a kiln, and calcined at 650°C for 0.5h to obtain activated light-burned magnesium, which is sieved with 60 mesh to remove uncombined and decomposed CaCO 3 As well as impurities such as silicate, further purification;

[0051] Grind the active light-burned magnesium to 200 mesh, mix the active light-burned magnesium and water in a weight ratio of 1:2 in a stirring tank, and stir at 60 rpm for 2 hours to obtain a magnesium hydroxide slurry;

[0052] Add ethylene glycol as a dispersant to the magnesium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com