Oyster fibers

A technology of fiber and oyster shell powder, applied in the field of textile fibers, can solve the problems of restricting the general popularization and application of calcium carbonate, and achieve the effects of large popularization and application potential, alleviation of processing pressure, high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

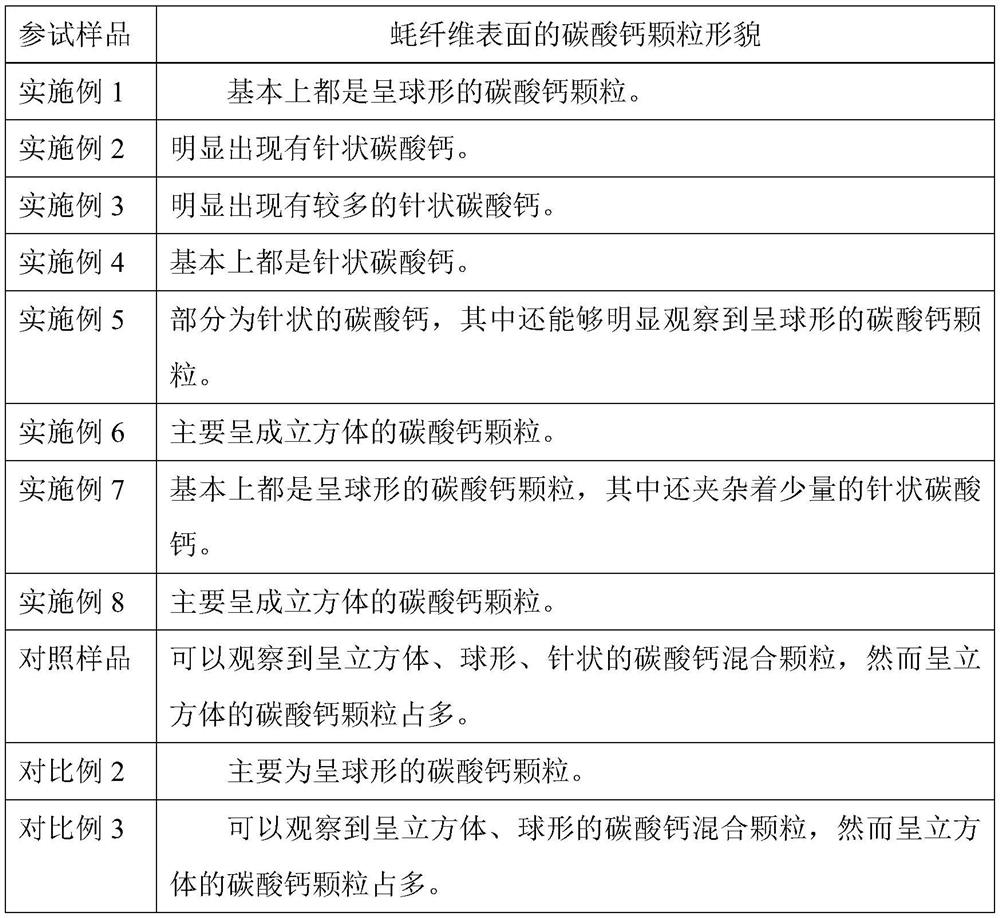

Examples

Embodiment 1

[0019] In this embodiment, polyamide resin is used as the polyester in the raw material, and methyl ethyl ketone is used as the dispersant, but in other embodiments, other types of polyester can be used according to actual conditions, and other volatile alcohols can be used , ketones, or aromatic compounds as dispersants, not limited to the use of polyamide resin as the polyester in the raw material or the use of butanone as the dispersant.

[0020] 1. Pretreatment steps of oyster shells

[0021] The oyster shells are cleaned, calcined at high temperature, cooled, and pulverized to obtain oyster shell powder.

[0022] 2. Ingredients

[0023] Accurately weigh 3 parts of oyster shell powder, 97 parts of polyamide resin, and 0.15 parts of glycine.

[0024] 3. Preparation of Oyster Fiber

[0025] Step 1: Dissolving oyster shell powder and chitosan in aqueous acetic acid to form a reaction solution with a chitosan concentration of 0.4 g / mL;

[0026] Step 2: adding urea to the r...

Embodiment 2

[0032] In this embodiment, polyamide resin is used as the polyester in the raw material, and methyl ethyl ketone is used as the dispersant, but in other embodiments, other types of polyesters can be used according to actual conditions, and other volatile alcohols, Ketones, or aromatic compounds, etc. are used as dispersants, and are not limited to the use of polyamide resin as the polyester in the raw material or the use of methyl ethyl ketone as the dispersant.

[0033] 1. Pretreatment steps of oyster shells

[0034] The oyster shells are cleaned, calcined at high temperature, cooled, and pulverized to obtain oyster shell powder.

[0035] 2. Ingredients

[0036] Accurately weigh 3 parts of oyster shell powder, 97 parts of polyamide resin, and 0.15 part of 3-alanine.

[0037] 3. Preparation of Oyster Fiber

[0038] Step 1: Dissolving oyster shell powder and chitosan in aqueous acetic acid to form a reaction solution with a chitosan concentration of 0.4 g / mL;

[0039] Step ...

Embodiment 3

[0045] In this embodiment, polyamide resin is used as the polyester in the raw material, and methyl ethyl ketone is used as the dispersant, but in other embodiments, other types of polyesters can be used according to actual conditions, and other volatile alcohols, Ketones, or aromatic compounds, etc. are used as dispersants, and are not limited to the use of polyamide resin as the polyester in the raw material or the use of methyl ethyl ketone as the dispersant.

[0046] 1. Pretreatment steps of oyster shells

[0047] The oyster shells are cleaned, calcined at high temperature, cooled, and pulverized to obtain oyster shell powder.

[0048] 2. Ingredients

[0049]Accurately weigh 3 parts of oyster shell powder, 97 parts of polyamide resin, and 0.15 parts of 5-aminovaleric acid.

[0050] 3. Preparation of Oyster Fiber

[0051] Step 1: Dissolving oyster shell powder and chitosan in aqueous acetic acid to form a reaction solution with a chitosan concentration of 0.4 g / mL;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com