Method for reducing hydrogen content of steel blanks

A technology for hydrogen content and billet, which is applied in the field of reducing hydrogen content of billets, can solve problems such as reducing hydrogen content of billets, and achieve the effects of reducing hydrogen content, less investment and solving control problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

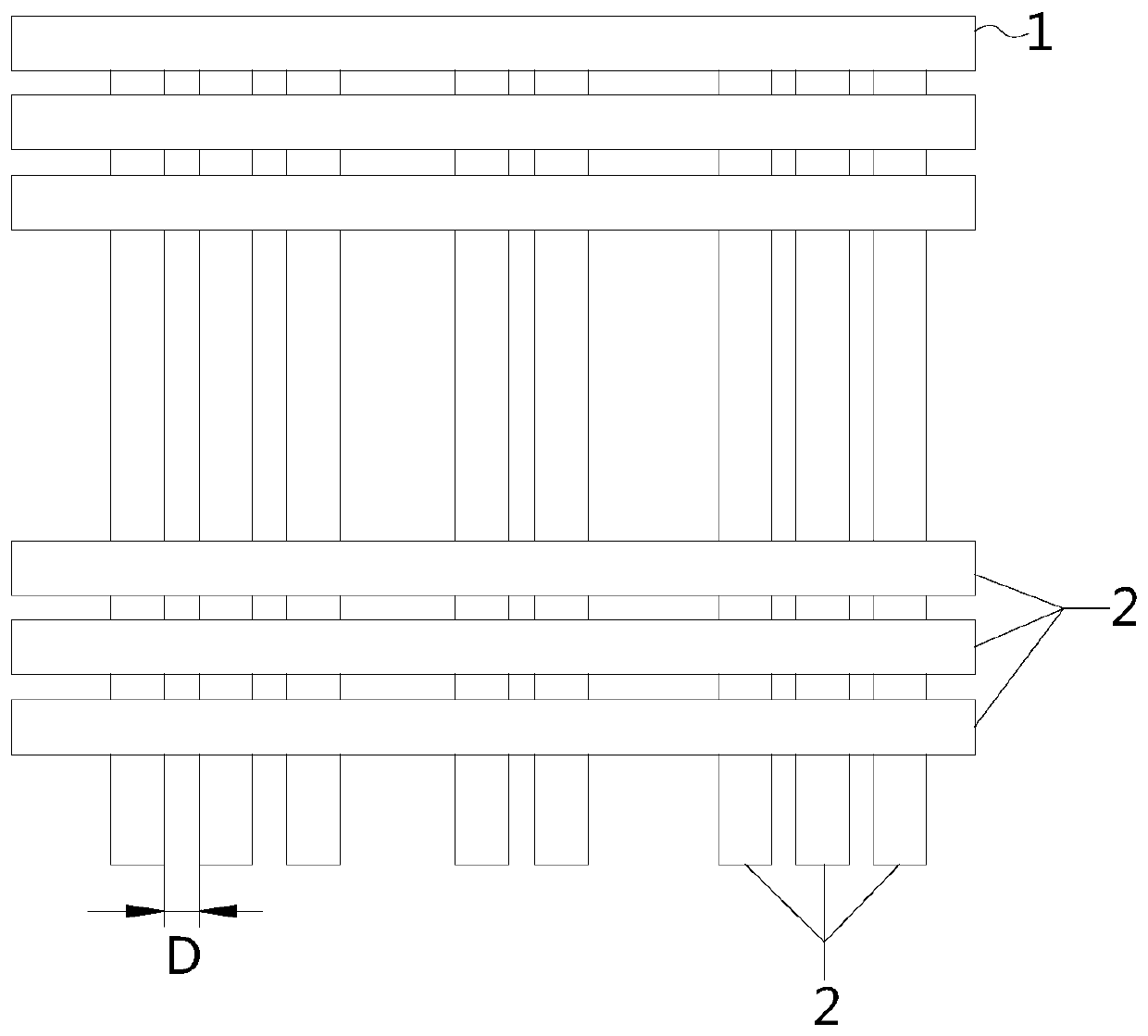

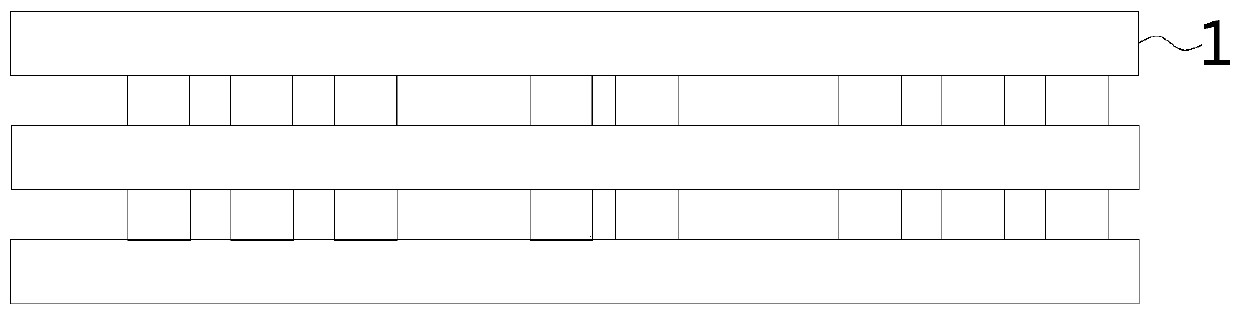

[0017] Such as figure 1 , figure 2 In the method for reducing the hydrogen content of steel slabs shown, the steel slabs 1 are stacked layer by layer from bottom to top, wherein the steel slabs 1 of the same layer are arranged parallel to each other, and the upper and lower adjacent two layers of steel slabs 1 are arranged vertically to each other. There are gaps between adjacent billets 1 of the same layer.

[0018] In actual operation, the stacks are required to be neat, stable, and in the shape of a well, and skewing and unevenness are strictly prohibited. The number of stacking layers for each stack is strictly regulated according to the section and the height of the factory building. In order to facilitate subsequent management and ensure product quality, it is preferable to make relevant records when billet 1 is off-line and stacked, and record information suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com