Preparation of Oxide Dispersion Strengthened Ferritic Steel by Surface Oxidation + Explosive Compaction

A technology of dispersion strengthening and ferritic steel, which is applied in the field of oxide dispersion strengthening steel, can solve the problems of high cost, low output, uneven distribution of oxides, etc., and achieve the effect of low cost, simple operation and increasing the number of oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A nanocomposite oxide dispersion-strengthened FeCr alloy is prepared, and the alloy composition is Fe-9Cr-0.3Ti-1.5W-0.2V-0.6Mn-0.5Y (mass percentage, the same below).

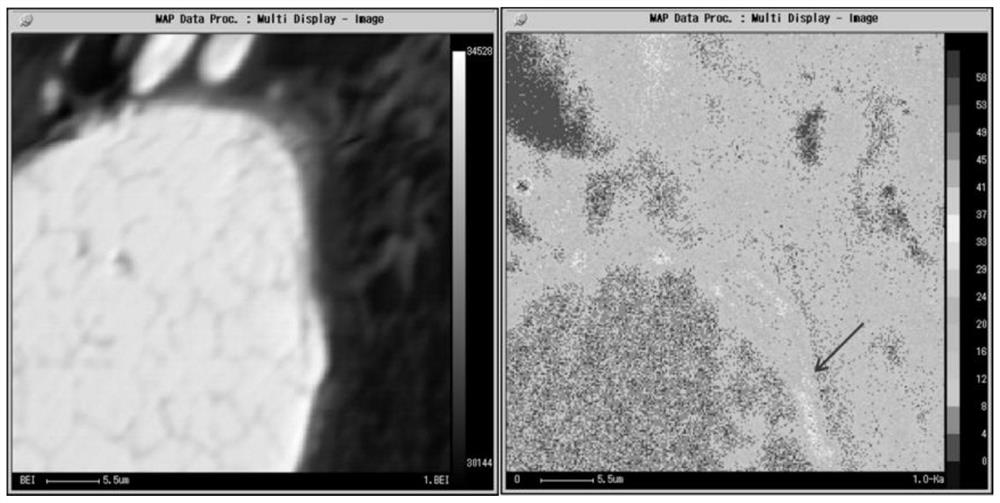

[0032] A 100kg vacuum induction furnace was used to melt the alloy ingot, and then argon gas spraying was used to make powder to obtain the iron-based alloy powder of the above composition. Screen the powder with a particle size of about 60 μm, put it in the quartz tube, turn on the molecular pump to extract the air inside the device, then slowly feed pure oxygen into the quartz tube, and at the same time adjust the gas fine-tuning valve and vacuum pump valve to control the iron in the quartz tube. The oxygen pressure in contact with the base alloy powder is 50Pa, and then the powder is heated to 325°C at a heating rate of 5°C / min, oxidized at a constant temperature for 24 hours, and then sealed and packaged. figure 1 It is the oxygen element distribution diagram of the iron-based alloy powder profile a...

Embodiment 2

[0034] Prepare nanocomposite oxide dispersion strengthened Fe-Cr-Al ferritic steel, the alloy composition is Fe-15Cr-4.5Al-0.5Ti-2.0W-0.1Si-0.1Y (mass percentage, the same below).

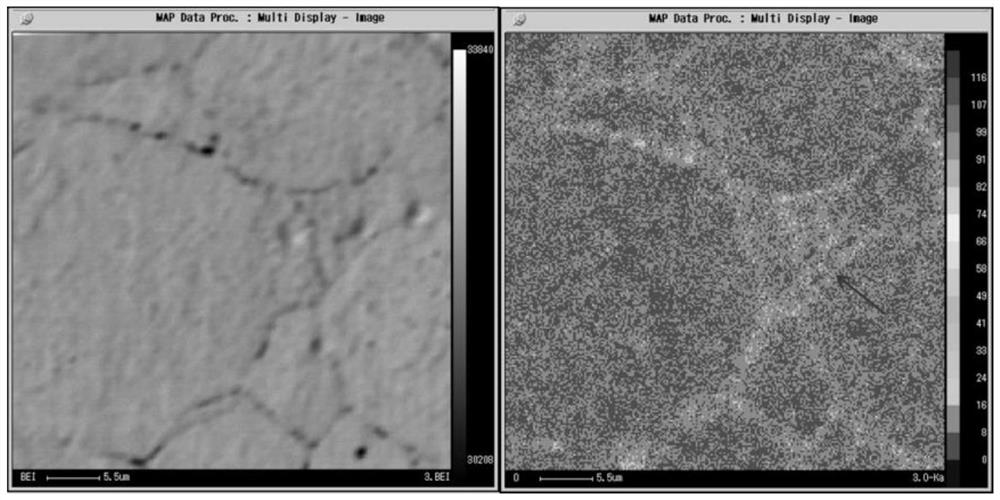

[0035] The alloy ingot was melted in a 50 kg vacuum induction furnace, and argon spray was used to prepare the above iron-based alloy powder containing Y. Screen out the powder with a particle size of 60-100um, put the powder in the quartz tube, turn on the molecular pump to extract the air inside the device, then oxidize the powder, vacuumize the powder in the quartz tube, and adjust the gas fine-tuning valve and The vacuum pump valve controls the oxygen pressure in contact with the iron-based powder to 20Pa, then heats the powder to 300°C at a heating rate of 5°C / min, and determines the constant temperature oxidation time to be 6h according to the Y content of the alloy powder. After oxidation, a continuous oxide film is formed on the surface of the powder, and the thickness of the oxide film is ab...

Embodiment 3

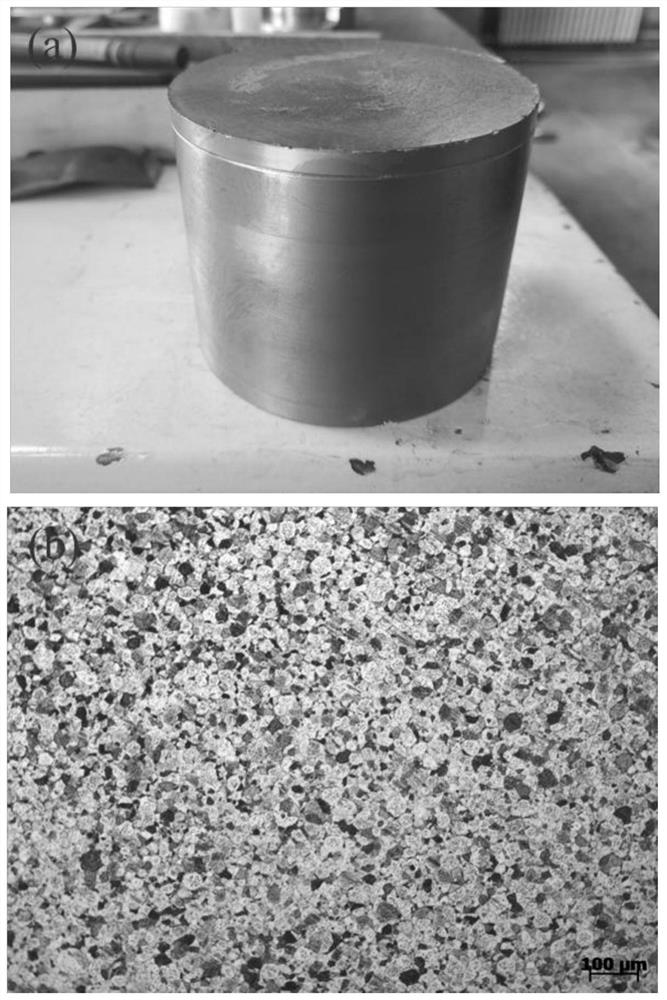

[0037] A nanocomposite oxide dispersion-strengthened Fe-Cr-Al ferrite alloy is prepared, and the alloy composition is Fe-14Cr-4Al-0.5Ti-2.0W-0.5Y.

[0038] The alloy ingot was smelted in a 50 kg vacuum induction furnace, and the iron-based alloy powder of the above components was obtained by argon spraying. Screen the powder with a particle size of 60-100 μm, put it in a quartz tube, turn on the molecular pump to extract the air inside the device, and then oxidize the powder at a heating rate of 5°C / min, oxygen pressure of 20Pa, and raise the temperature to 350°C. Seal the package after constant temperature for 30h. After oxidation, a continuous oxide film is formed on the surface of the powder, and the thickness of the oxide film is about 18.5nm. Before explosive compaction, the powder needs to be pre-compressed in the press, and the load applied by the press is 80 tons, and then the oxidized powder is placed in the explosive compaction mold, and the powder-to-drug ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com