A reverse circulation drilling system and reverse circulation drilling method

A reverse circulation and drilling technology, applied in drilling equipment and methods, drilling equipment, wellbore/well components, etc., can solve the problems of high cost and production difficulty, achieve the goal of reducing drilling friction, reducing cost and improving life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

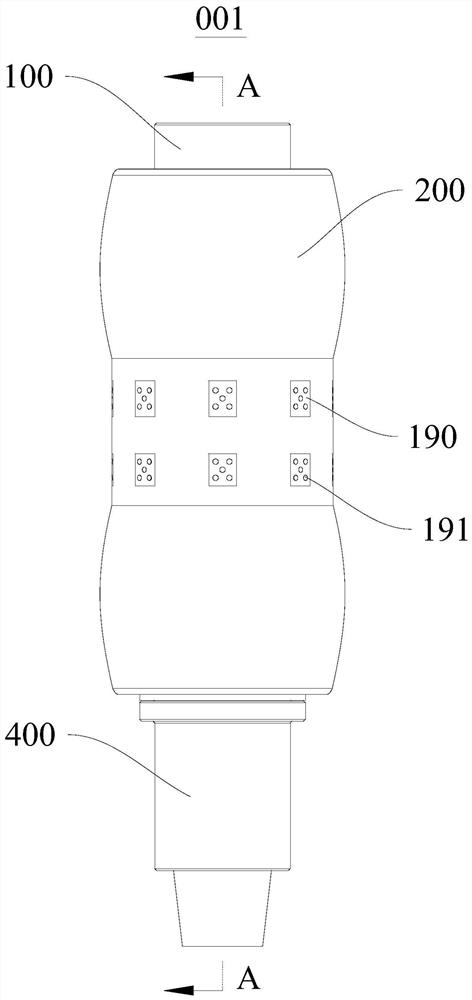

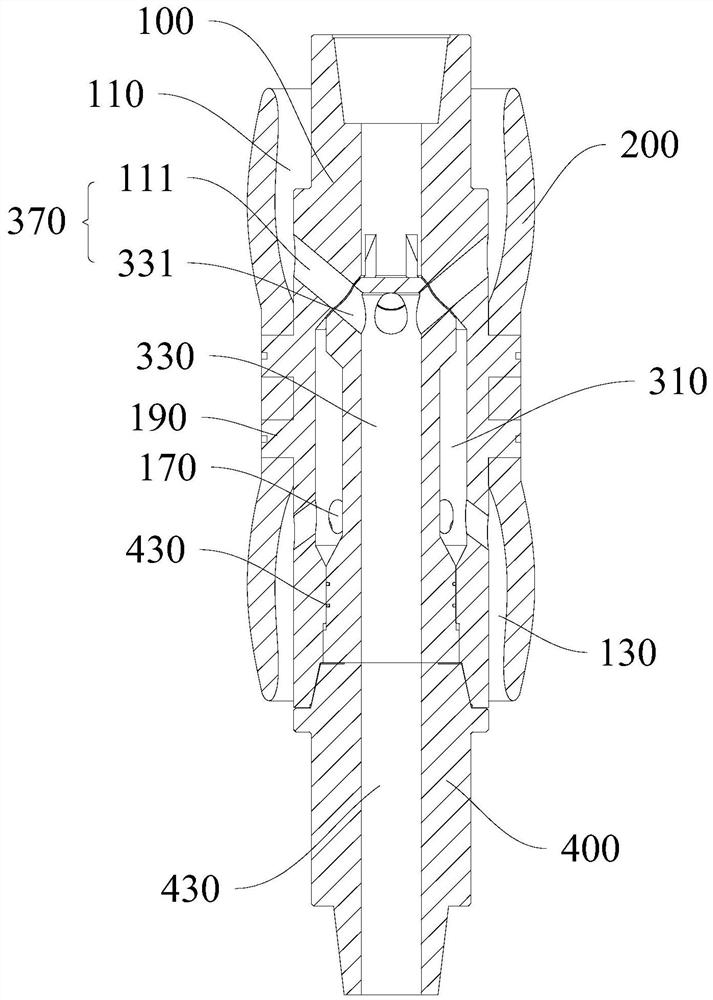

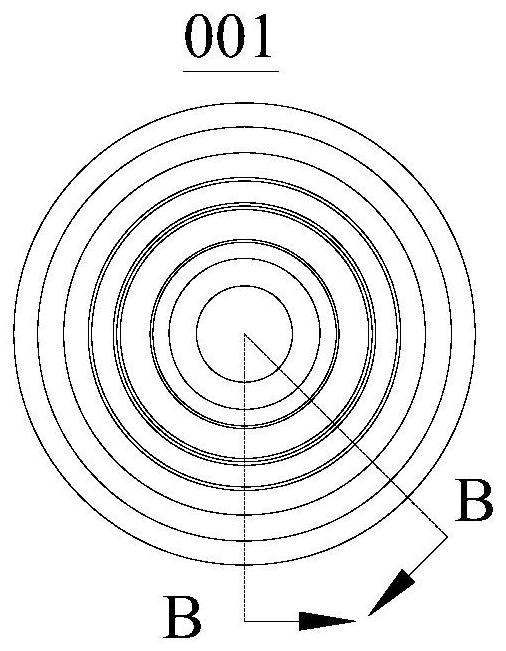

[0051] This embodiment provides a reverse circulation drilling system, please refer to figure 1 , figure 2 , image 3 and Figure 4 , this reverse circulation drilling system includes a casing 600 , a circulation channel switching nipple 001 , a first drill pipe 710 , a second drill pipe 730 and a drill bit 800 .

[0052] The casing 600 is lowered into the well after the drilling of the previous wellbore is completed, and the drilling wall is reinforced with cement, and the inside of the casing 600 is formed as a working wellbore 610 for the lower open-hole drilling.

[0053] The reverse circulation drilling circulation channel switching nipple 001 includes an upper joint 100 , a rubber plug 200 , a reversing mandrel 300 and a lower joint 400 , wherein the rubber plug 200 is sleeved on the outside of the upper joint 100 .

[0054] see Figure 11 and Figure 12 , the reverse circulation drilling circulation channel switching nipple 001 is installed in the working wellbore...

Embodiment 2

[0077] This embodiment provides a reverse circulation drilling method, please refer to Figure 11 and Figure 12 , this reverse circulation drilling method is implemented using the reverse circulation drilling system provided by Embodiment 1, including steps:

[0078] a. Run the casing 600 for cementing after the completion of the last drilling;

[0079] b. Statistically drill 800 feet of drill bits at different depths in the drilled block, and use the average drill bit 800 feet as the estimated drilling depth data D for each drilling trip i , select the drill bit 800 and the second drill rod 730;

[0080] c. Run into the drilling tool, and the drilling depth reaches L i At the same time, install the circulation channel switch sub-joint 001 at the end of the second drill pipe 730, install the first drill pipe 710 at the other end of the circulation channel switch sub-joint 001, and continue drilling to extend the drill bit 800 to the bottom of the well, wherein, L i than D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com