Mechanical pile forming device for base-expanded poured foundation pile and pile forming method thereof

A mechanical and pile-forming technology, which is applied in the direction of drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve the problems of difficult excavation in hard soil layers, low construction efficiency of bottom-expanding cast-in-place piles, etc., and achieve the goal of construction High efficiency, reduced construction costs, and small disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

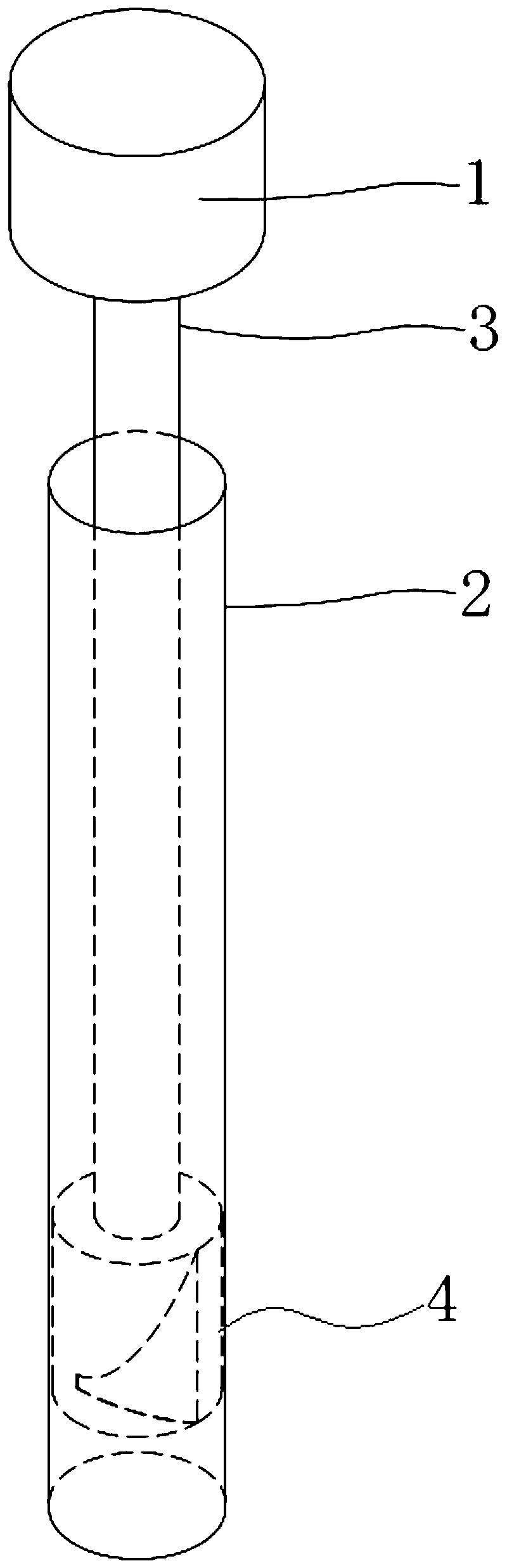

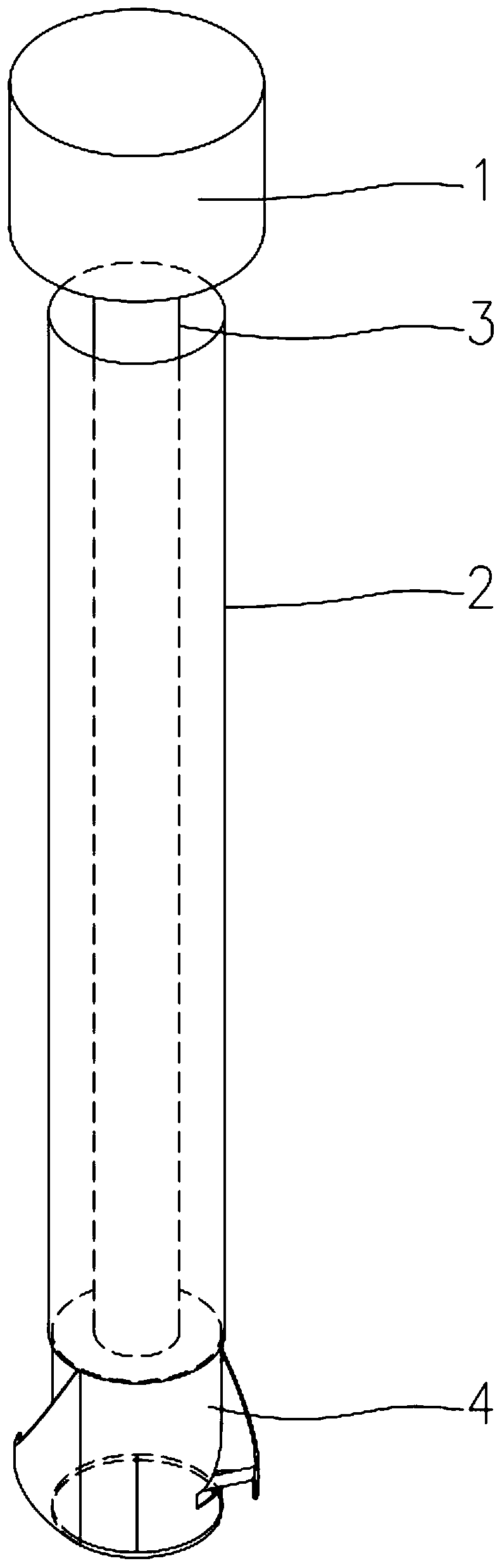

[0032] attached by figure 1 , 2 Shown: a mechanical pile-forming device for bottom-expanding cast-in-situ piles, the device includes a power rotating head 1 that provides power for the rotating shaft, a rotating transmission shaft 3 (hollow steel pipe) connected under the power rotating head 1, and a set At the steel pipe casing 2 on the outside of the rotating transmission shaft 3, a reaming drill bit 4 that is connected to the rotating transmission shaft 3 ends.

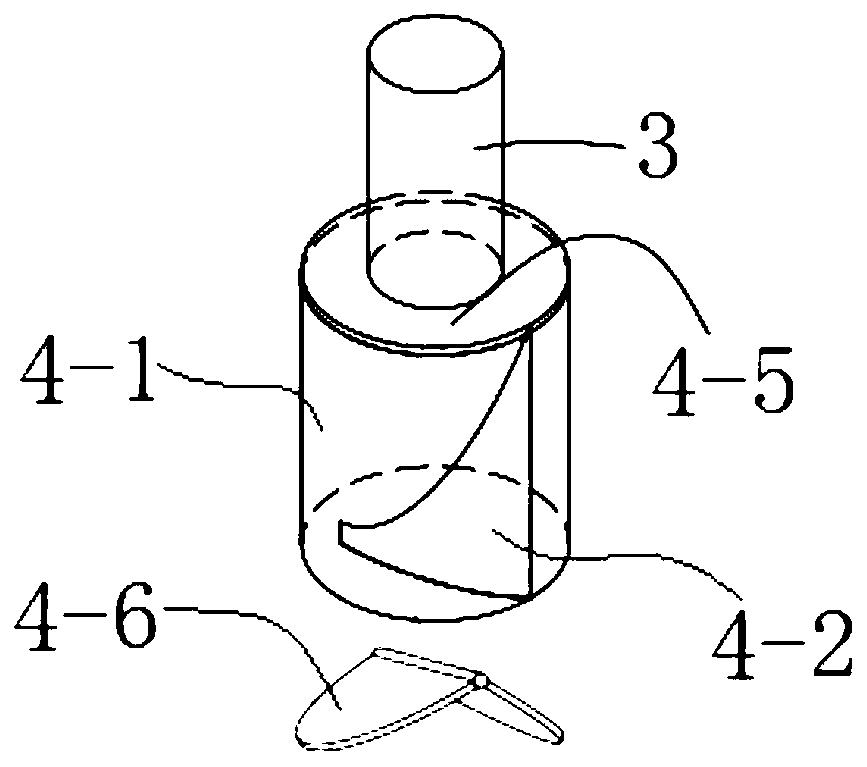

[0033] attached by image 3 , 4 As shown: the bottom reaming drill bit 4 is composed of a barrel-shaped bottom reaming drill bit main body 4-1, a mechanical opening and reaming blade 4-2, a hydraulic device for opening and closing the reaming blade 4-3, a hydraulic control conduit 4-4, and a drill top plate 4-5 and the mechanical opening and closing bottom plate 4-6, the two me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com