Bearing fault detection device and detection method

A fault detection and bearing technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as difficulty in fault feature extraction, low accuracy, and complex signal processing in fault diagnosis methods, and achieve Strong anti-interference ability, strong sensitivity and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

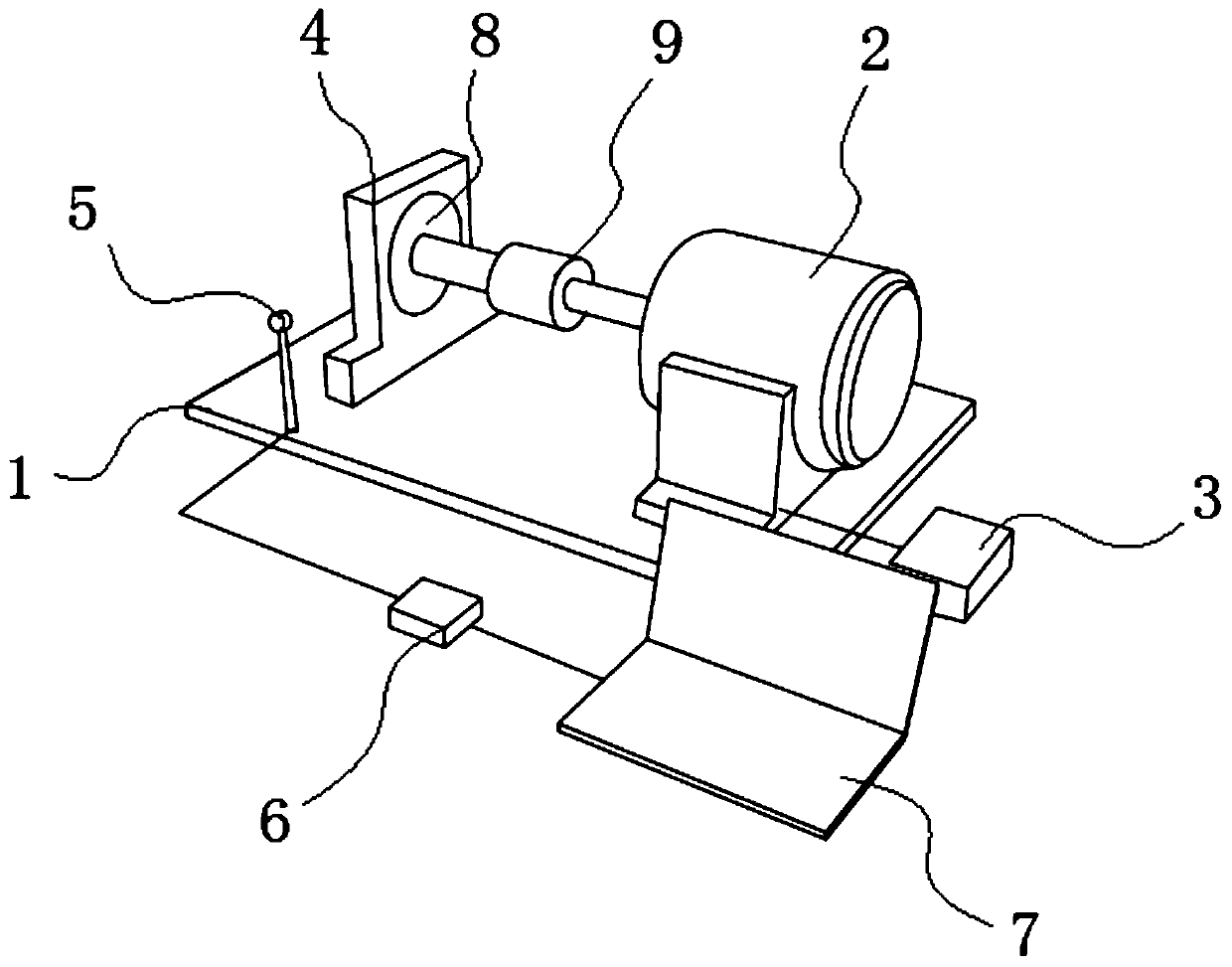

[0036] Such as figure 1 As shown, a bearing fault detection device includes a workbench 1, a DC geared motor device, a bearing seat 4, a laser self-mixing interference device 5, a data acquisition and analysis device 6, and a computer 7. The DC geared motor device, the bearing The seat 4 and the laser self-mixing interference device 5 are all arranged on the worktable 1, the bearing 8 to be detected is installed on the bearing seat 4, the DC geared motor device is connected to the bearing 8, and the laser The self-mixing interference device 5 is arranged on the side of the bearing housing 4, the laser self-mixing interference device 5 is connected to the data acquisition and analysis device 6, and the data acquisition and analysis device 6 is connected to the computer 7. The present invention overcomes the To solve the problems of traditional bearing fault diagnosis methods relying too much on expert experience, difficult fault feature extraction, and complex signal processing...

Embodiment 2

[0051] This embodiment is similar to the first embodiment, the difference is that this embodiment verifies the non-damaged bearing and the faulty bearing on the basis of the first embodiment, mainly including the following steps:

[0052] Step 1: Fix the non-destructive bearing in the bearing housing;

[0053] Step 2: Adjust the laser self-mixing interference device to obtain a self-mixing signal;

[0054] Step 3: Turn on the DC gear motor, the non-destructive bearing will rotate with the rotation of the DC gear motor, and adjust the speed of the DC gear motor to increase it from 1.3rpm to 22.1rpm;

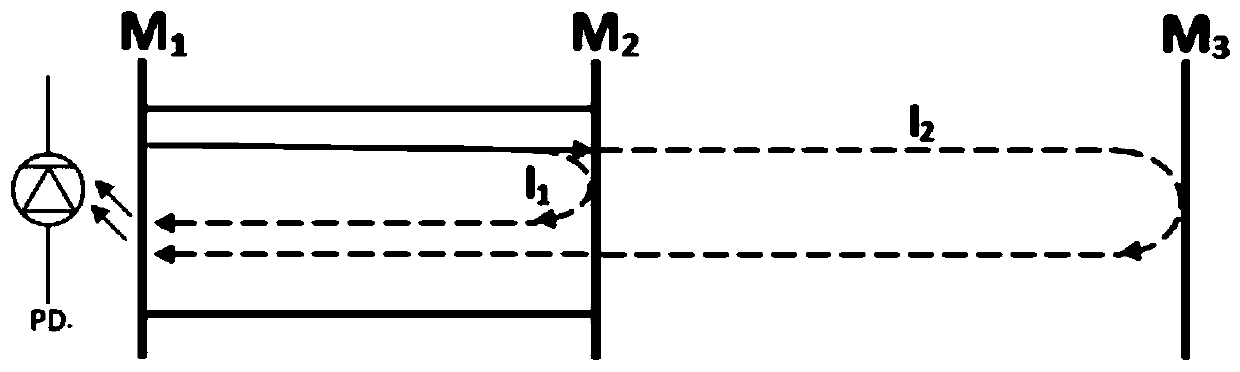

[0055] Step 4: Use the laser self-mixing interference device to measure the vibration of the non-destructive bearing. The three-mirror cavity model equivalent to the bearing housing and the laser self-mixing interference device is as follows: figure 2 Shown, M 1 , M 2 are the two end faces of the laser in the laser self-mixing interference device, M 3 is the side of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com