Chimney tail gas sampling tube and using method thereof

A technology for sampling pipes and exhaust gas, which is applied in the direction of sampling, sampling devices, measuring devices, etc. It can solve the problems of different caliber positions and chimney height positions, and achieve the effect of reducing shaking and preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

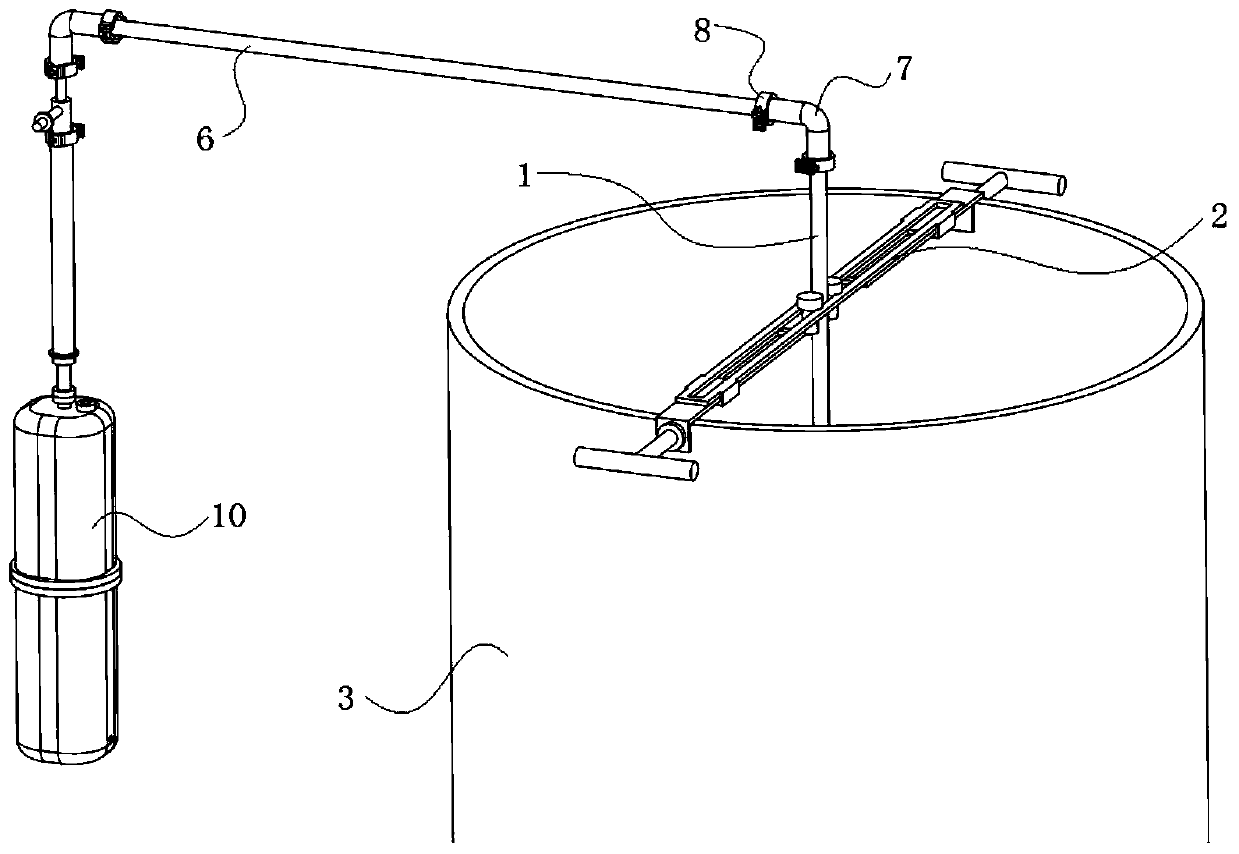

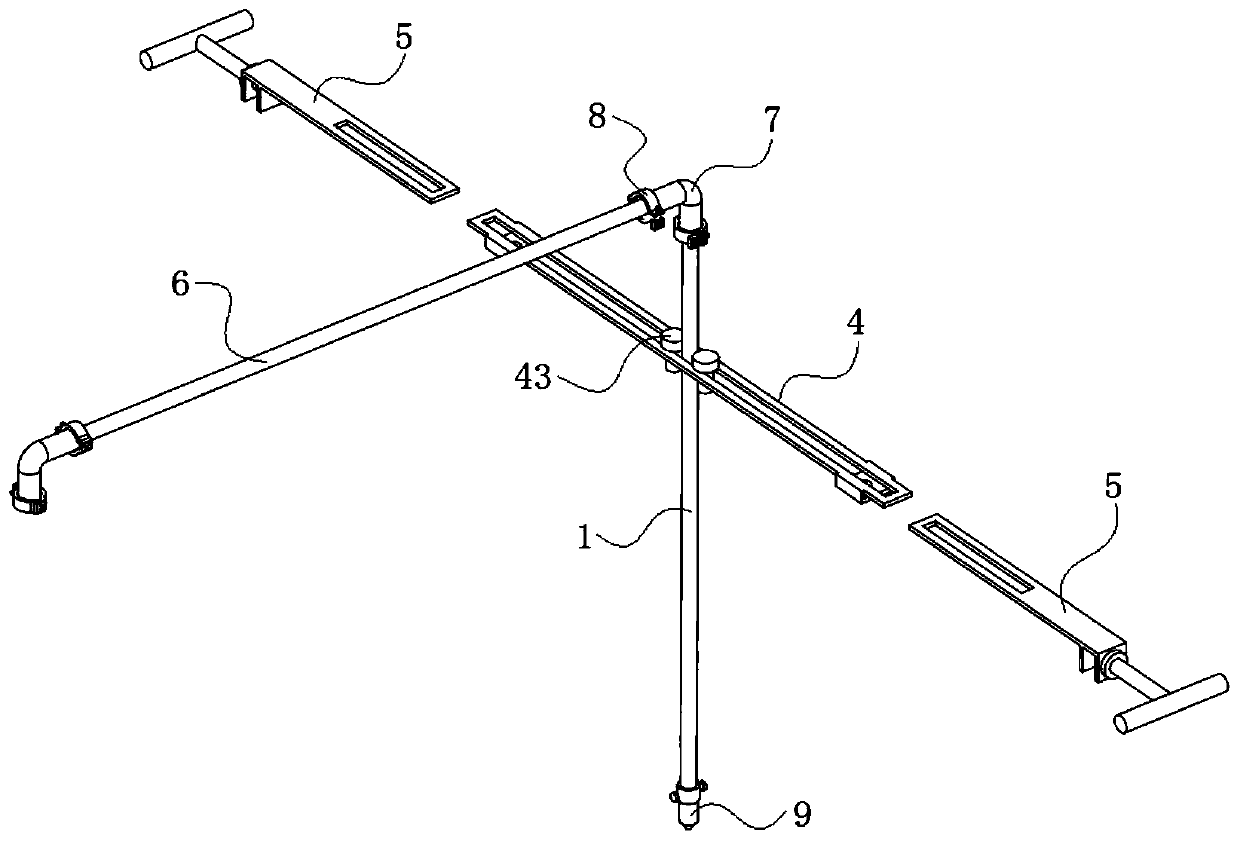

[0034] like Figure 1-2 As shown, this embodiment provides a chimney tail gas sampling pipe, which includes a collection pipe 1 and a fixing mechanism 2. The collection pipe 1 is vertically fixed to the chimney discharge port 3 through the fixing mechanism 2 to collect chimney tail gas.

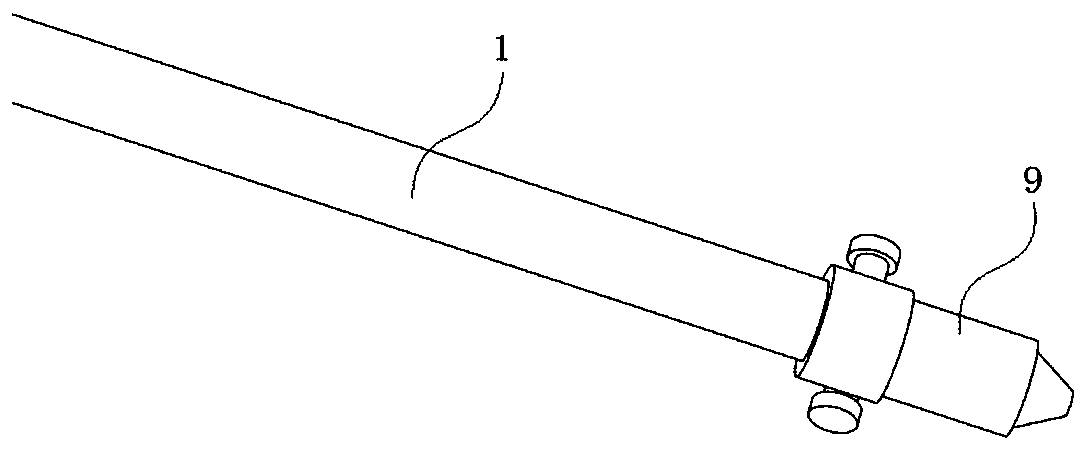

[0035] Wherein, the collection pipe 1 is a bendable copper pipe, and the copper collection pipe 1 can be bent into a corresponding shape according to the radian of the chimney pipe on site, so that it can be smoothly inserted into the chimney. At the same time, a sampling nozzle 9 is provided at the collection end of the collection pipe 1, and the sampling nozzle 9 is threadedly connected with the collection pipe 1. By replacing the sampling nozzle 9 with a different size and matching with a reasonable sampling flow rate, the constant velocity sampling of the flue gas can be realized, such as image 3 shown.

[0036] Further, the fixing mechanism 2 includes a fixing plate 4 and a fixing clip...

Embodiment 2

[0052] like Figure 8 As shown, this embodiment also provides a chimney tail gas sampling pipe, the structural principle is the same as that of embodiment 1, the difference is that this embodiment is used in the case where the diameter of the chimney discharge port 3 is small, and the fixing mechanism 2 does not include Fixed plate 4.

[0053] The fixing mechanism 2 of this embodiment is a fixing clip 4, including two side fixing clips 4 that are linearly symmetrical. The collection tube 1 passes through the overlapping first clamping section 511, is clamped by the first clamping section 511, and can adjust its position back and forth along the first clamping section 511. After the specific position of the collection tube 1 is determined, in its Tighten the threaded parts 43 on both sides to prevent the collection tube 1 from moving. In addition, if the fixing strength is sufficient, the fixing clip 5 on one side can also be used alone for clamping and fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com