Allocation center cargo quantity prediction method and device

A forecasting method and forecasting device technology, applied in forecasting, data processing applications, instruments, etc., can solve problems such as long cargo turnover time, low platform utilization, limited transfer venues, etc., to improve the core competitiveness of enterprises, improve The effect of customer satisfaction and improved turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

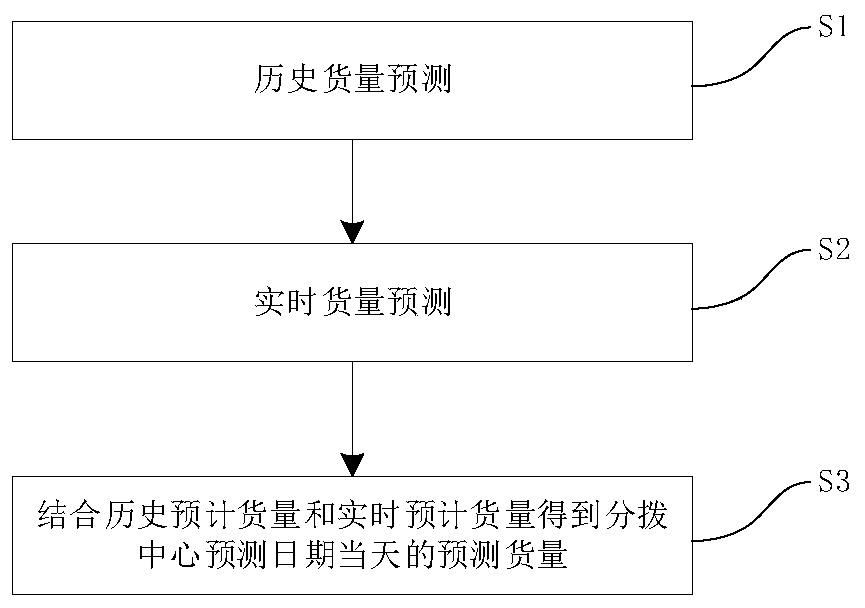

[0054] Embodiment 1 of the present invention provides a method for forecasting cargo volume in a distribution center, figure 1 It is a flow chart of realization of a distribution center cargo volume forecasting method provided by the embodiment of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0055] S1: Historical cargo volume forecast: Calculate the historical estimated cargo volume on the forecast date based on the historical cargo volume of the distribution center;

[0056]S2: Real-time cargo volume forecast: obtain the cargo volume in stock and calculate the real-time estimated cargo volume on the forecast date based on the order cargo information. The real-time cargo volume forecast includes: outbound real-time cargo volume forecast and inbound real-time cargo volume forecast;

[0057] S3: Combining the historical estimated cargo volume and the real-time estimated cargo volume to obtain the forecasted cargo volume on the...

Embodiment 2

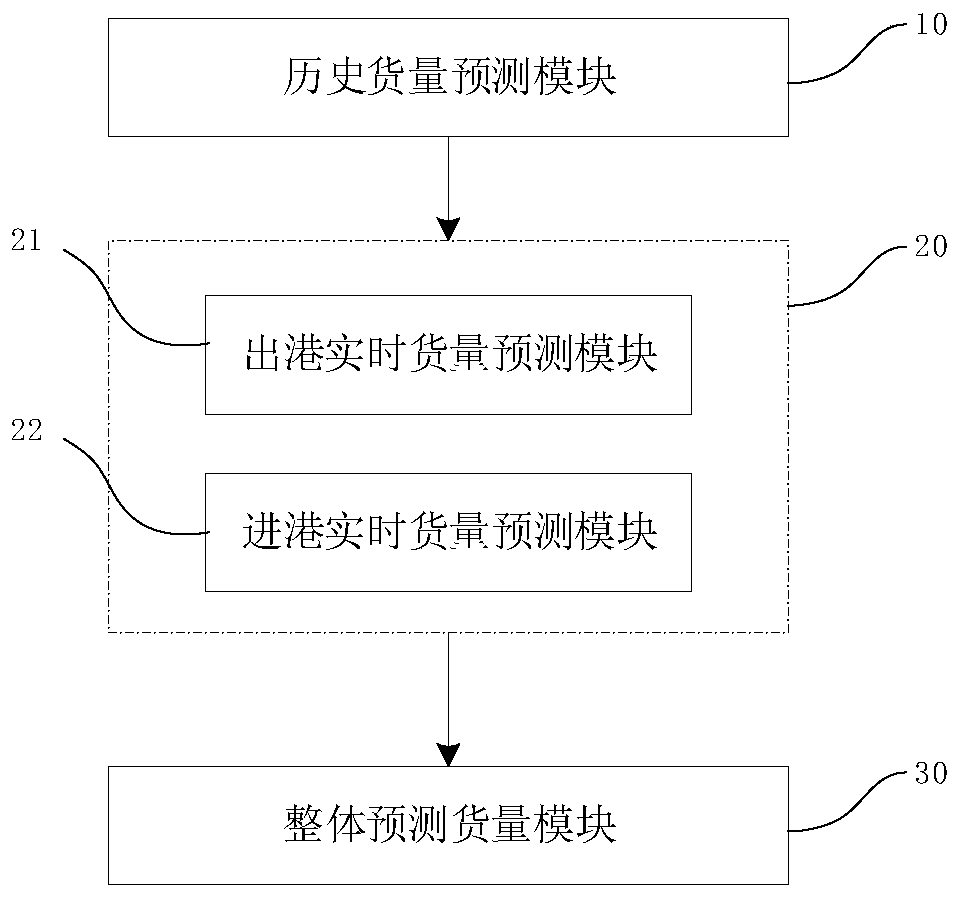

[0086] This embodiment provides a cargo volume forecasting device for a distribution center, which is used to implement the method described in Embodiment 1. Such as figure 2 As shown, it is a structural block diagram of the cargo volume forecasting device of the distribution center in this embodiment, including:

[0087] Historical cargo volume forecasting module 10: used to calculate historical forecasted cargo volume on the forecast date based on the historical cargo volume of the distribution center, wherein the historical forecasted cargo volume forecast includes: outbound historical forecasted cargo volume forecast and inbound forecasted cargo volume forecast;

[0088] Real-time cargo volume forecasting module 20: used to obtain the cargo volume in stock and calculate the real-time estimated cargo volume on the forecast date based on the order cargo information, wherein the real-time cargo volume forecast includes: outbound real-time cargo volume forecast and inbound re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com