Relay iron core mounting mechanism capable of realizing direct falling type feeding

A technology for mounting mechanisms and relays, applied to relays, circuits, electrical components, etc., can solve the problems of low manual installation efficiency of relay cores, achieve stable and reliable mounting mechanisms, and improve yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

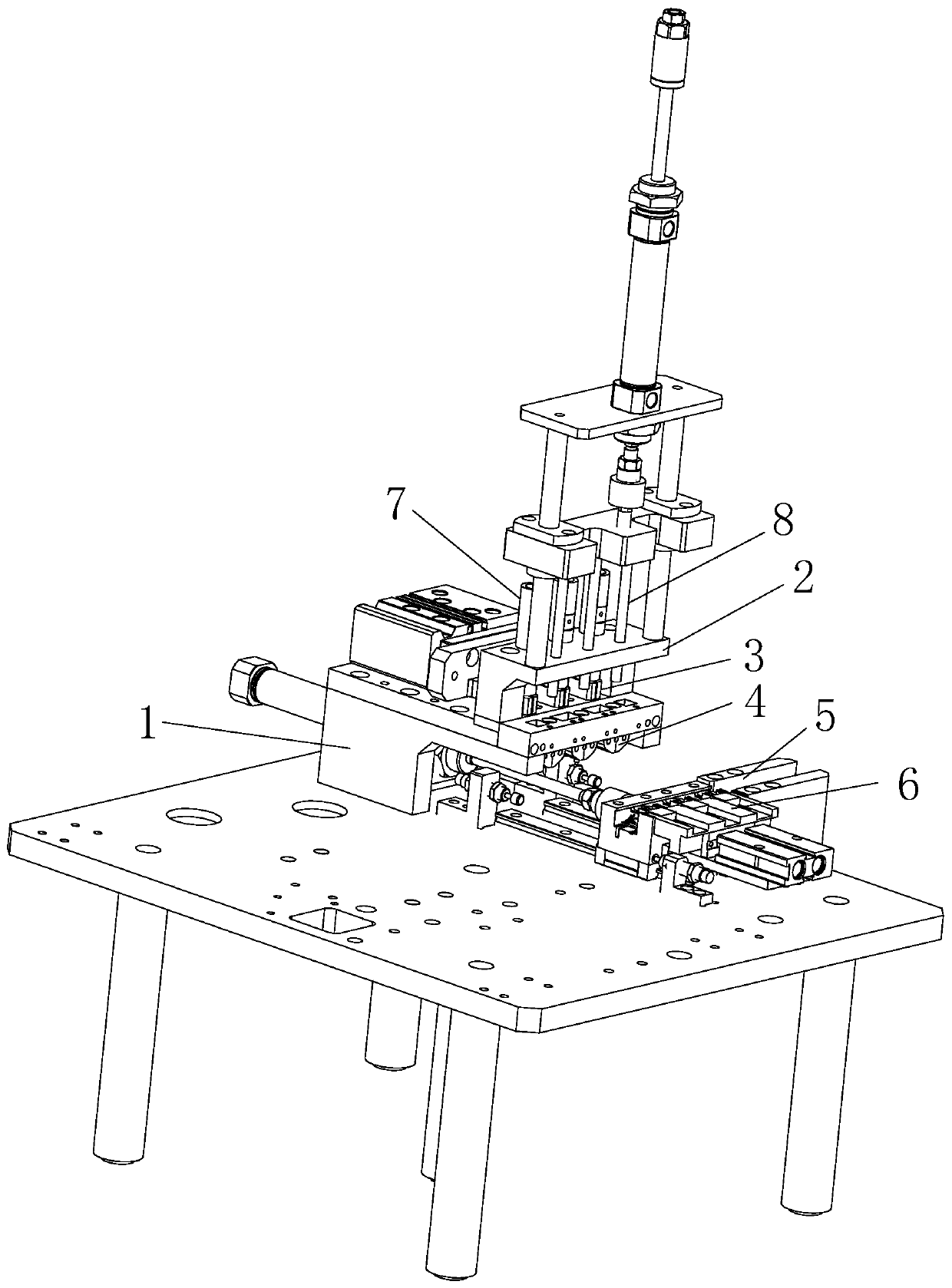

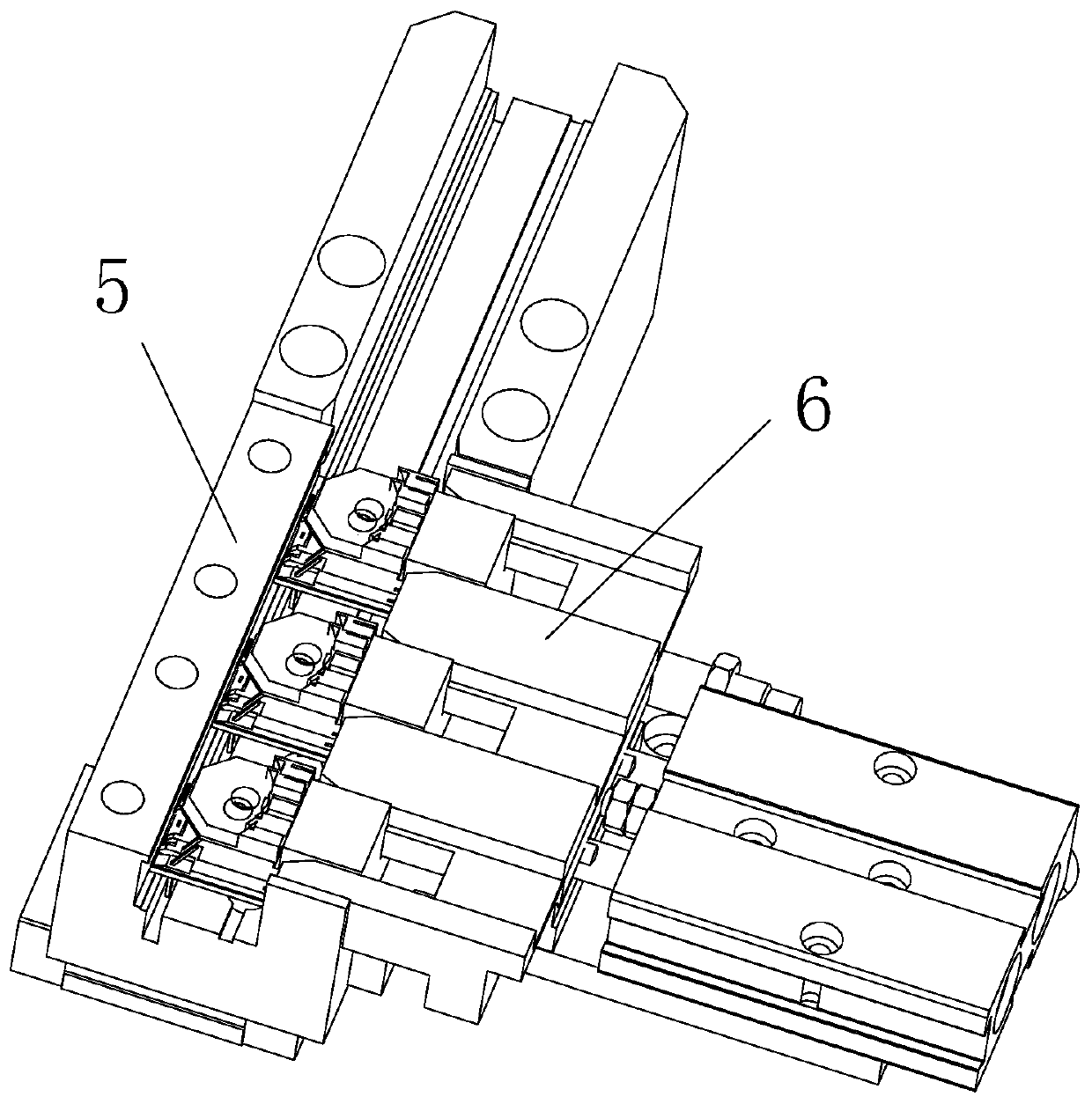

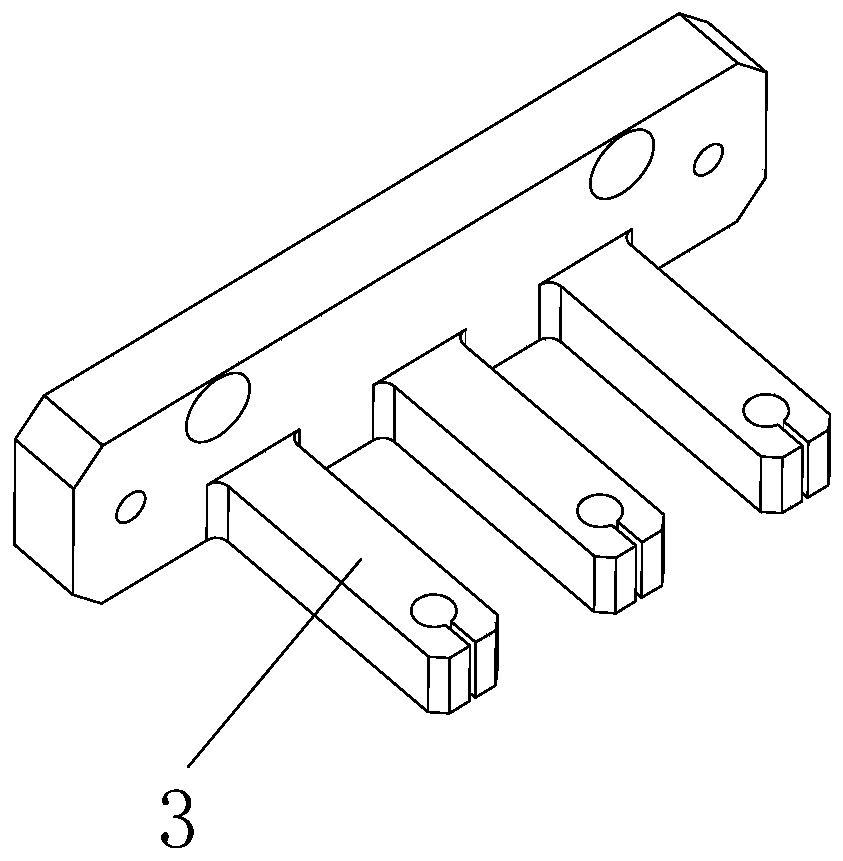

[0022] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0023] Such as Figure 1 to Figure 4 As shown in the figure, a relay iron core installation mechanism capable of straight-fall feeding includes a base on which a workbench 1 is arranged, and an L-shaped pressing platform 2 is arranged on the working platform 1. The rear end of the horizontal plate of the pressing platform 2 is vertical There is at least one iron core inlet, and at least one iron core push block 3 that can move back and forth along the workbench 1 is arranged on the workbench 1 below the iron core inlet, and an iron core is vertically opened on the iron core push block 3 The vertical trough for accommodating the iron core runs through the core pushing block 3 up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com