A device for stripping the insulation layer at the end of a cable

A technology of insulating layer and cable end, which is applied in the field of cable stripping, can solve the problems of high labor intensity, low work efficiency, and difficult stripping, and achieve the effect of small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

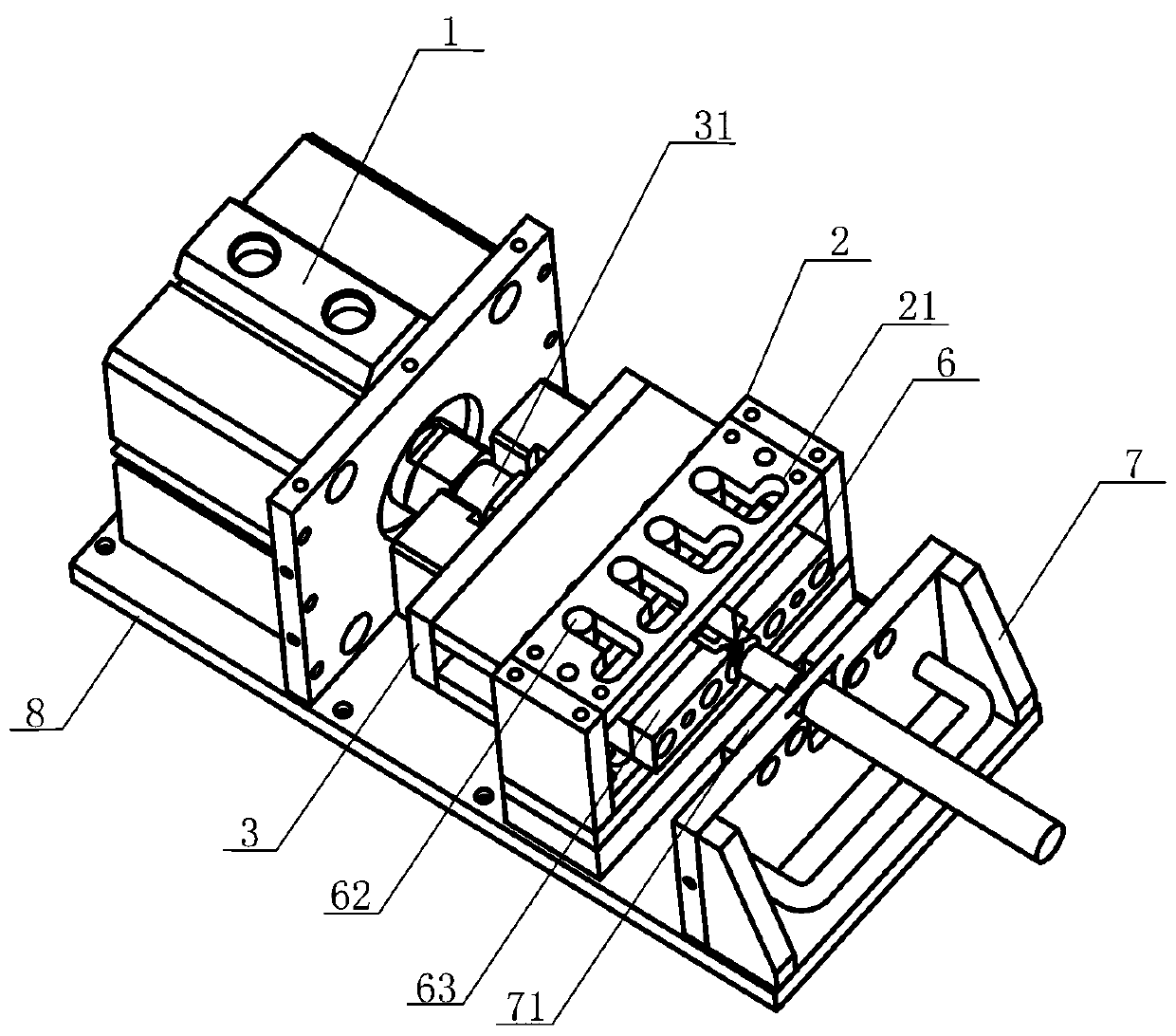

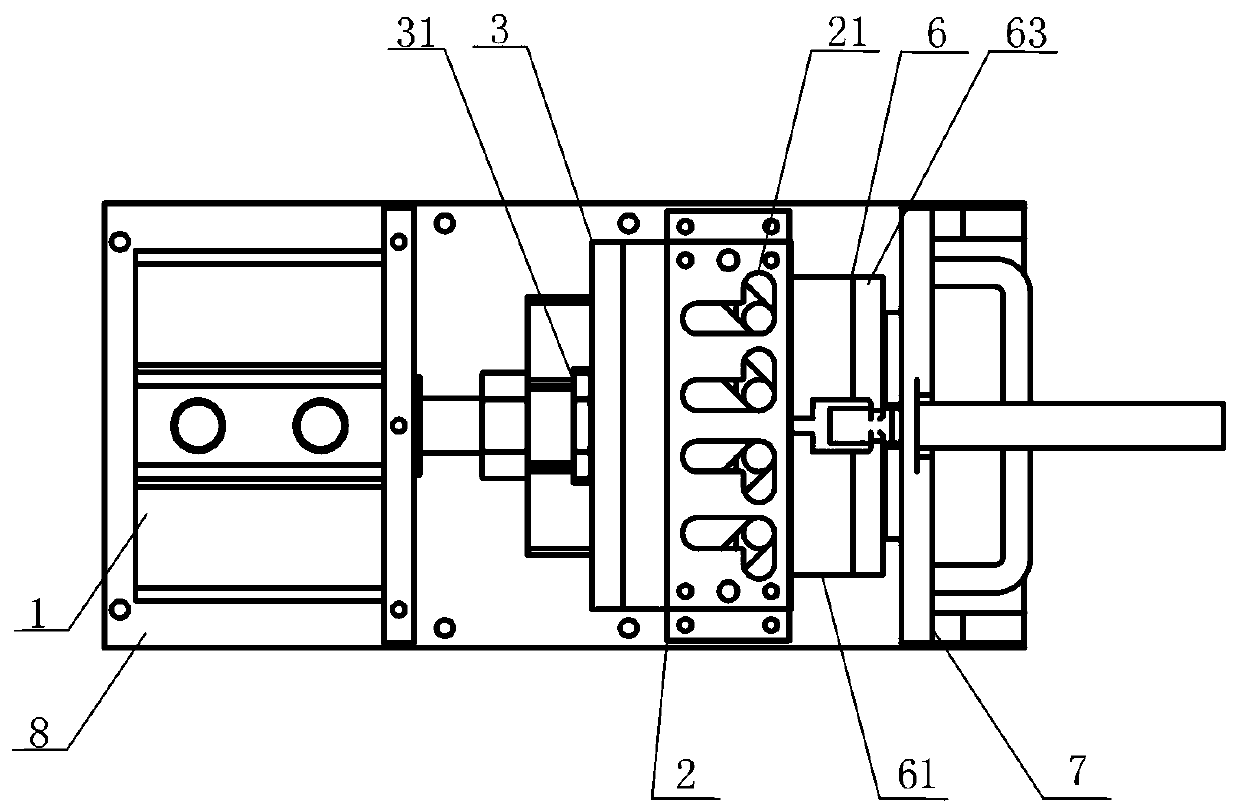

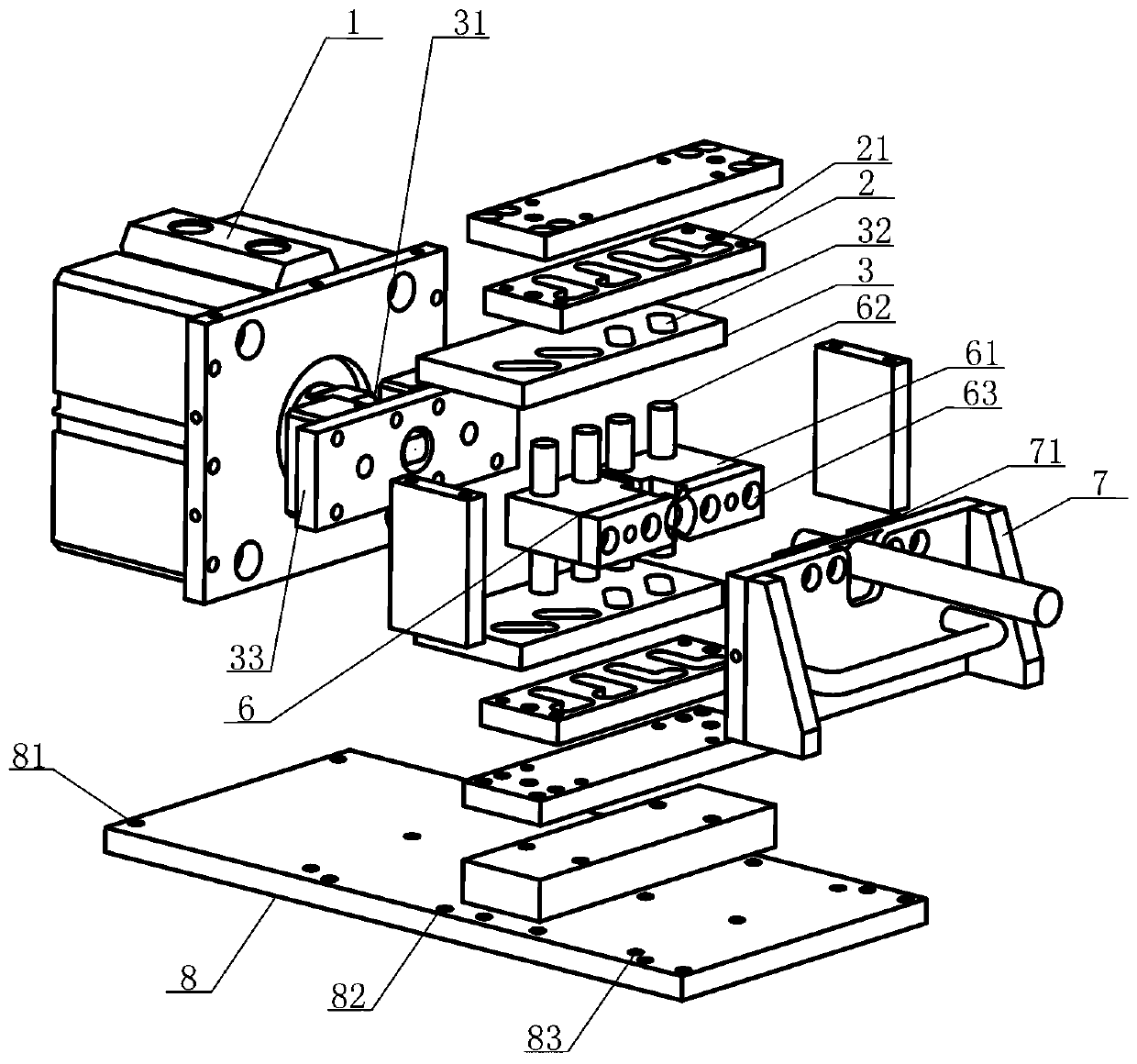

[0022] refer to figure 1 , figure 2 , image 3 , the present invention includes a cylinder 1, a guide box 2, a power plate 3, a cutter assembly 6, a cable fixing frame 7 and a bottom plate 8;

[0023] The bottom plate 8 is provided with a cylinder seat 81, a guide box seat 82 and a cable fixing frame seat 83 sequentially along the axis;

[0024] The guide box 2 is composed of a "mouth"-shaped frame and two guide plates up and down. The guide plate is symmetrically provided with an "L"-shaped guide groove 21, and the guide plate is symmetrically arranged on the top surface and the top surface of the frame. bottom surface;

[0025] The power plate 3 is composed of a vertical plate 33 and two flat plates arranged in parallel up and down, wherein the vertical plate is provided with a cylinder joint 31, and the upper and lower two flat plates are symmetrically provided with chute 32;

[0026] Described cutter assembly 6 is made up of a pair of knife seat 61, sliding shaft 62 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com