Method and device for producing a nonwoven fabric from fibres

A non-woven fabric, fiber technology, applied in the direction of non-woven fabrics, manufacturing tools, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

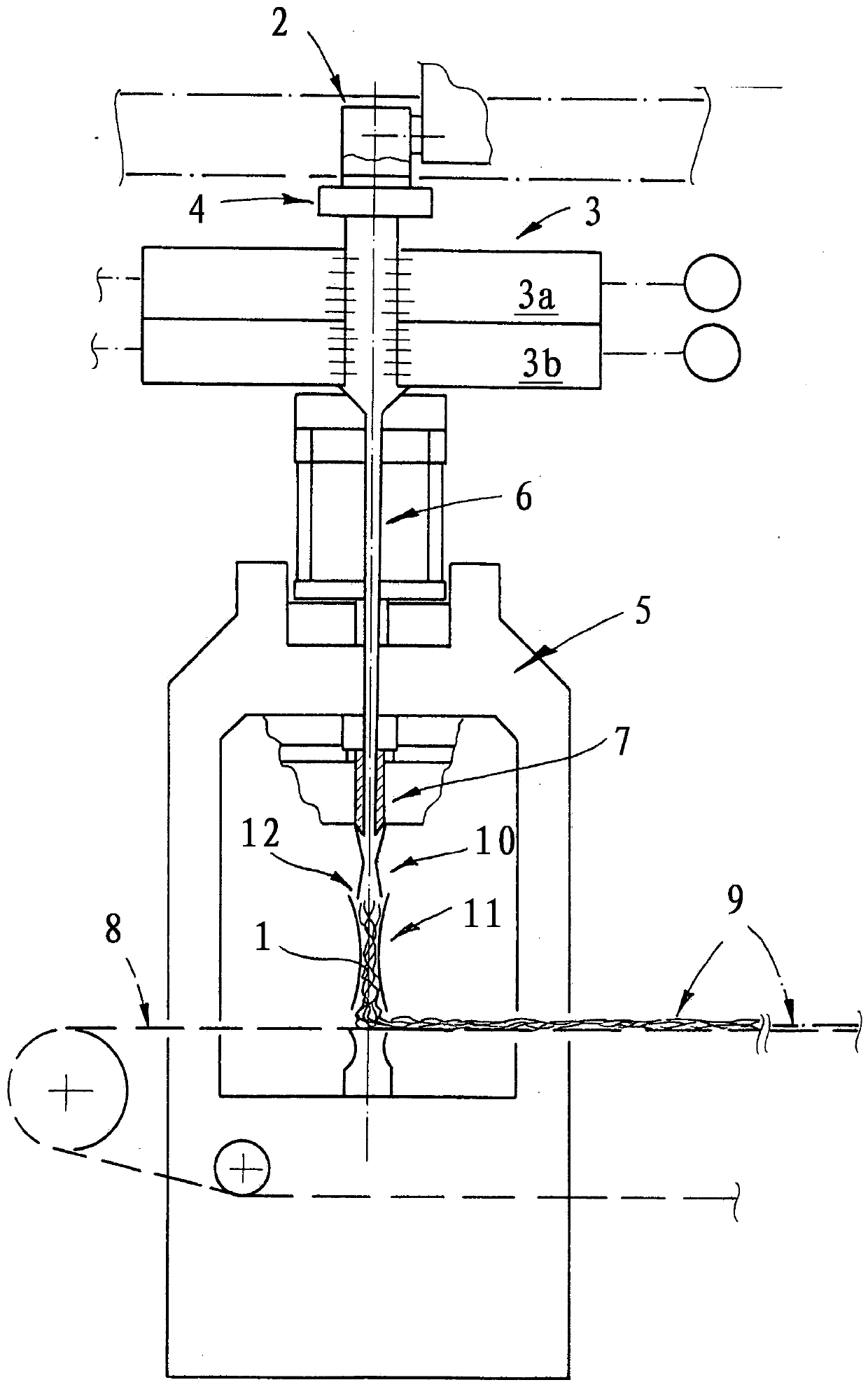

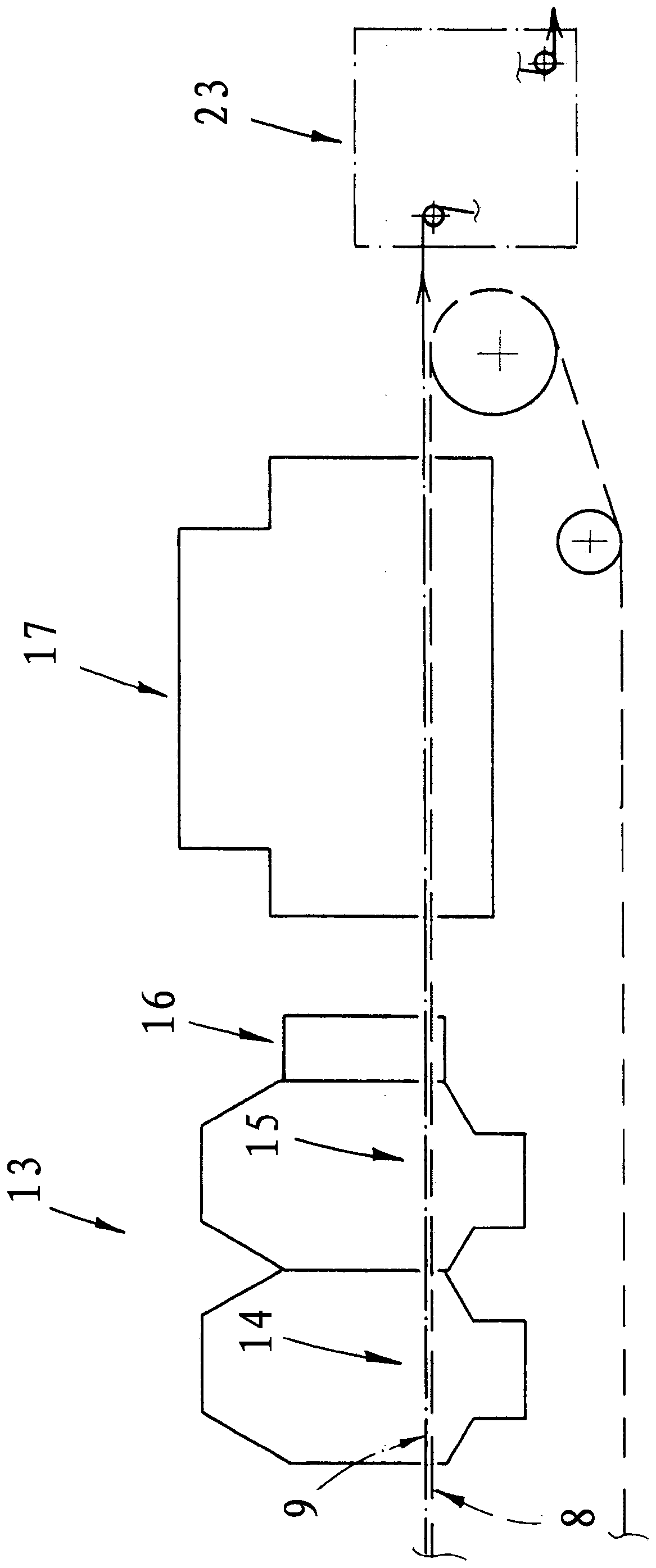

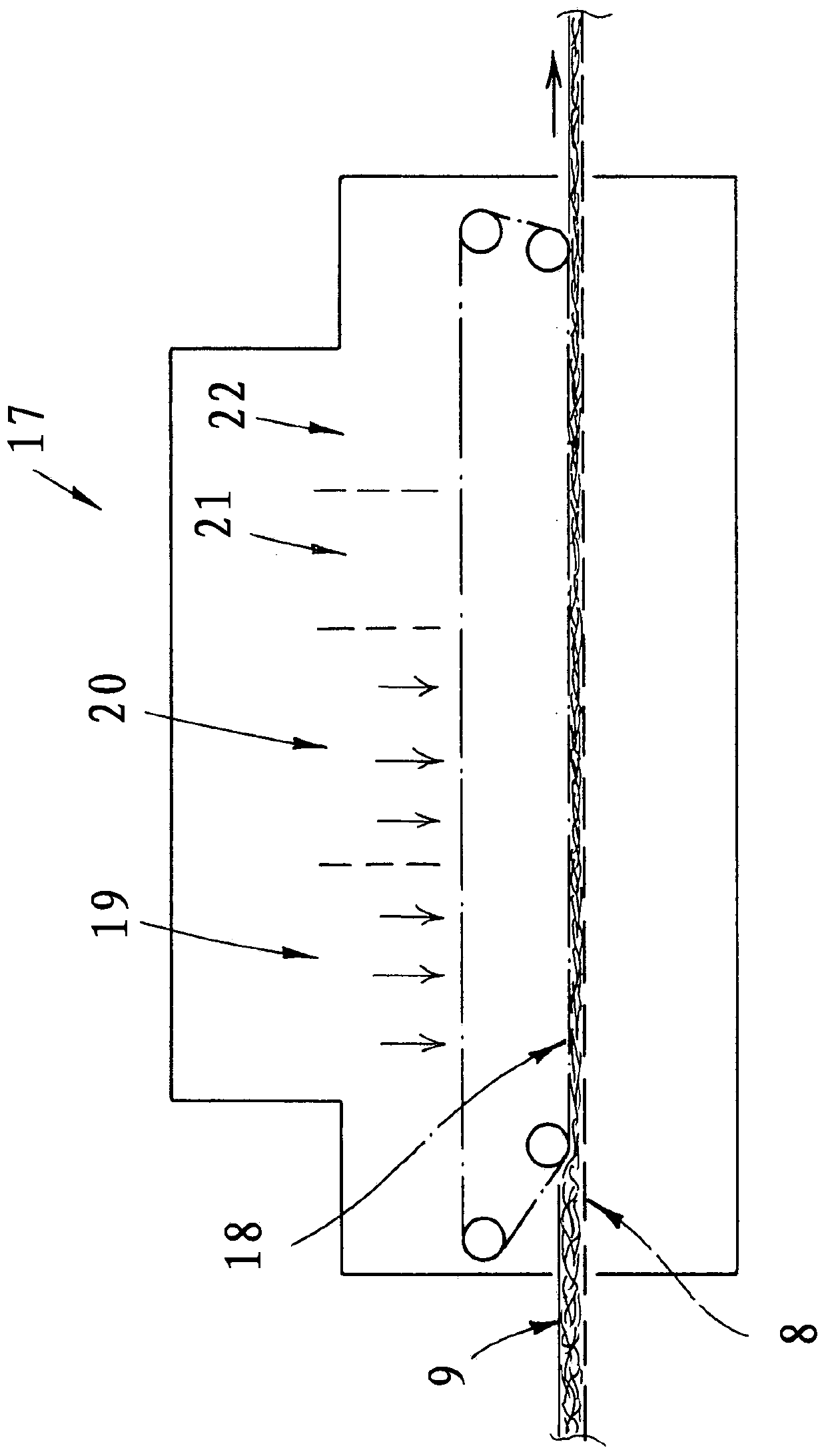

[0030] The drawing shows a device according to the invention for producing a spunbonded nonwoven made of continuous filaments 1 . According to a preferred embodiment of the invention, the continuous thread 1 consists of a thermoplastic and particularly preferably of a polyolefin. exist figure 1 The plant shown in is a spunbond nonwoven plant for the production of spunbond nonwovens made of continuous filaments 1 . With the device according to the invention, a continuous filament 1 is spun out by means of a spinneret 2 and subsequently cooled in a cooling device 3 . According to a preferred embodiment and in this exemplary embodiment, a monomer suction device 4 is arranged between the spinneret 2 and the cooling device 3 for suctioning the spinning fumes generated in the intermediate space. Preferably and in this exemplary embodiment, the cooling device 3 has two cooling chambers 3a, 3b arranged one above the other or one after the other in the direction of flow of the filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com