Device for regenerating and layering mixed-bedresin

A technology of mixed bed resin and layering device, applied in the direction of ion exchange bed cleaning/flushing, etc., can solve the problems of water output fluctuation, resin layer disorder, unsatisfactory hydraulic backwash layering effect, etc., to save water resources, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the working principle and process of the present invention, as well as the purpose and effect achieved, clearly understood, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

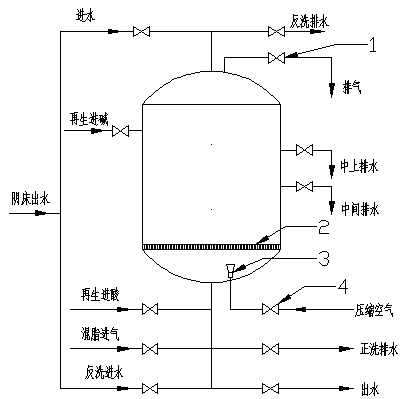

[0011] Refer to attached figure 1 , The embodiment of the present invention is realized by adopting the following technical scheme, which consists of a compressed air intake valve, a low-frequency sound wave generator, a water distribution device, and an exhaust valve connected in series from bottom to top. A mixed-bed resin regeneration and stratification device, characterized in that the backwashing and stratification steps are as follows: when the mixed-bed ion exchanger is backwashing and stratifying, the backwashing water inlet valve and the middle and upper drain valves are opened, and the middle and upper drain valves are discharged. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com