High-fiber food material crusher

A high-fiber, pulverizer technology, applied in grain processing and other directions, can solve the problems of high energy consumption for pulverization, poor pulverization, and incompatibility of dry and wet materials, and achieves the effect of low energy consumption for pulverization and smooth flow of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

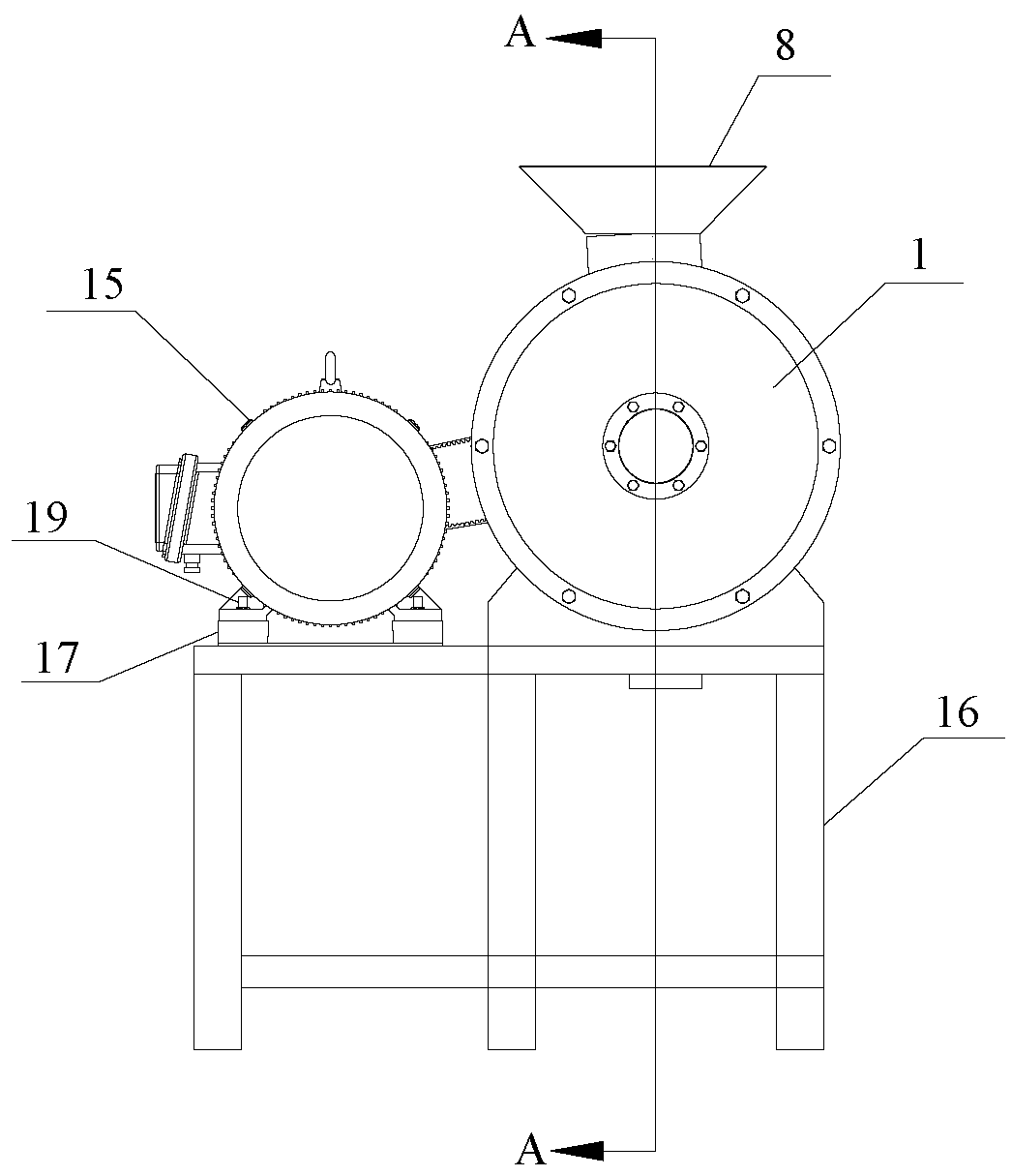

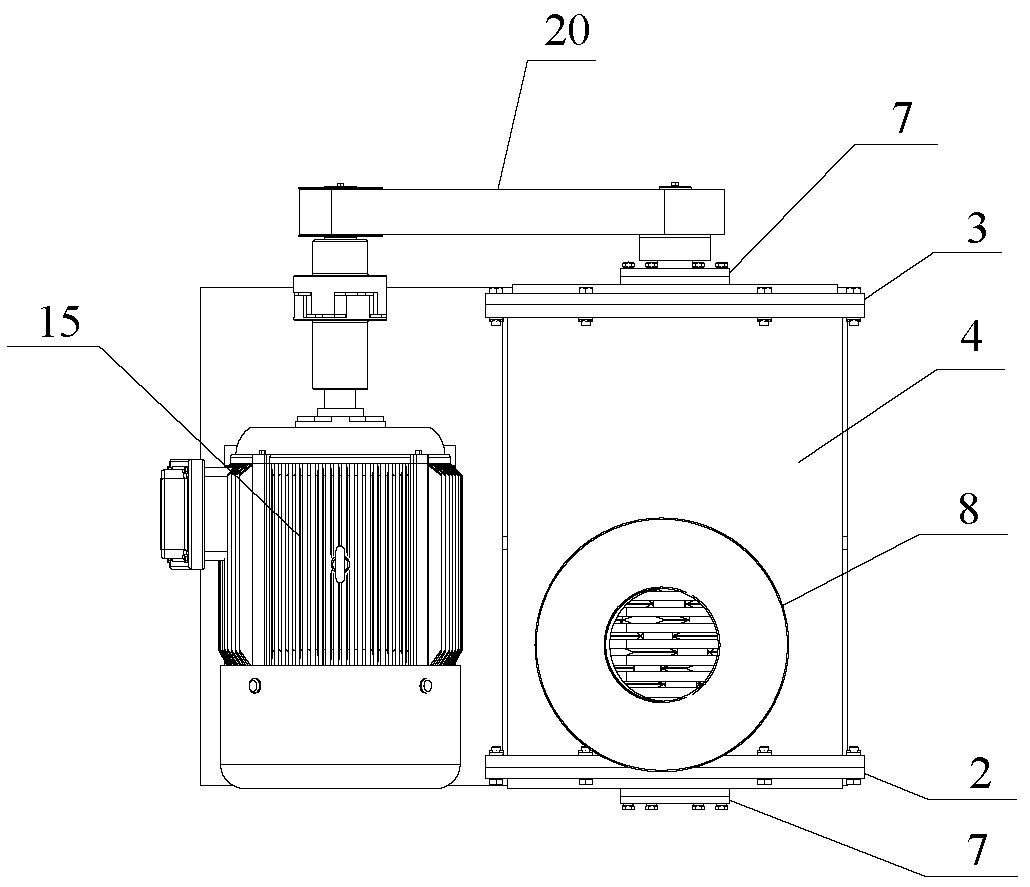

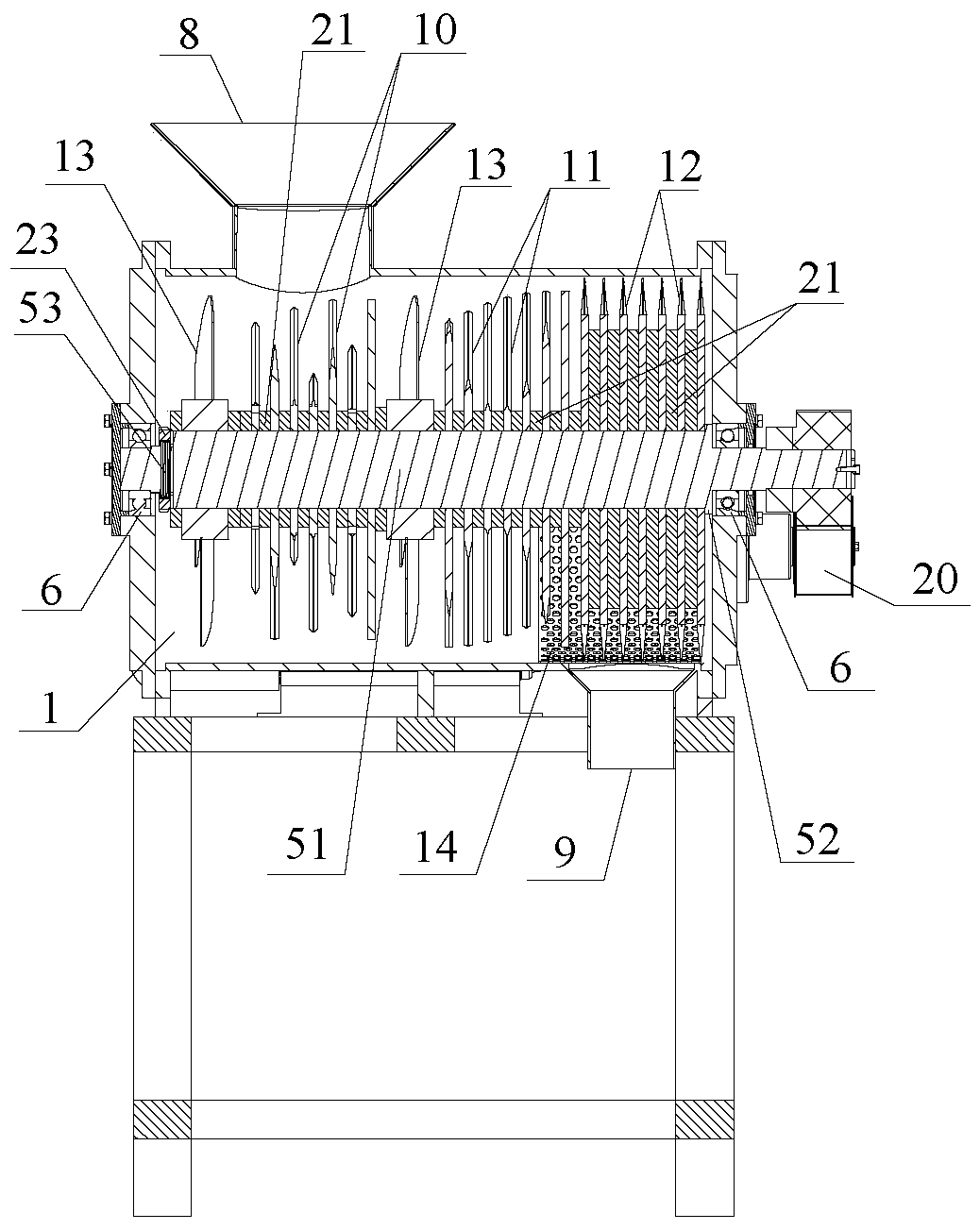

[0027] See Figure 1 to Figure 8 , a kind of high-fiber food material pulverizer of the present invention, it comprises the pulverizing chamber 1 that is arranged horizontally and is cylindrical, pulverizing chamber 1 comprises left end cover 2, right end cover 3 and cylinder side wall 4, cylinder side wall 4 The two ends of the shaft are fixedly connected with the left end cover 2 and the right end cover 3 respectively by bolts, and the crushing chamber 1 is provided with a rotating shaft 5 along the axial direction. The corresponding bearings 6 on the cover 2 and the right end cover 3 are respectively fixedly connected with a bearing end cover 7, and one end of the rotating shaft 5 passes through the crushing chamber 1 and is connected to the rotary driving mechanism; The bottom of the other end has a discharge port 9; along the discharge direction on the rotating shaft 5, several blades one 10, several blades two 11 and several blades three 12 are fixedly installed at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com