Heat management system of vehicle power battery

A technology of thermal management system and power battery, applied in the field of thermal management system, can solve the problems of long development cycle, high component cost, hindering the widespread development of new energy vehicles, etc., achieve easy modularization and standardization, and solve the problem of sharp drop in output, The effect of simplifying bicycle development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described, and it should be noted that the embodiments described here are only used for illustration, and do not limit the present invention:

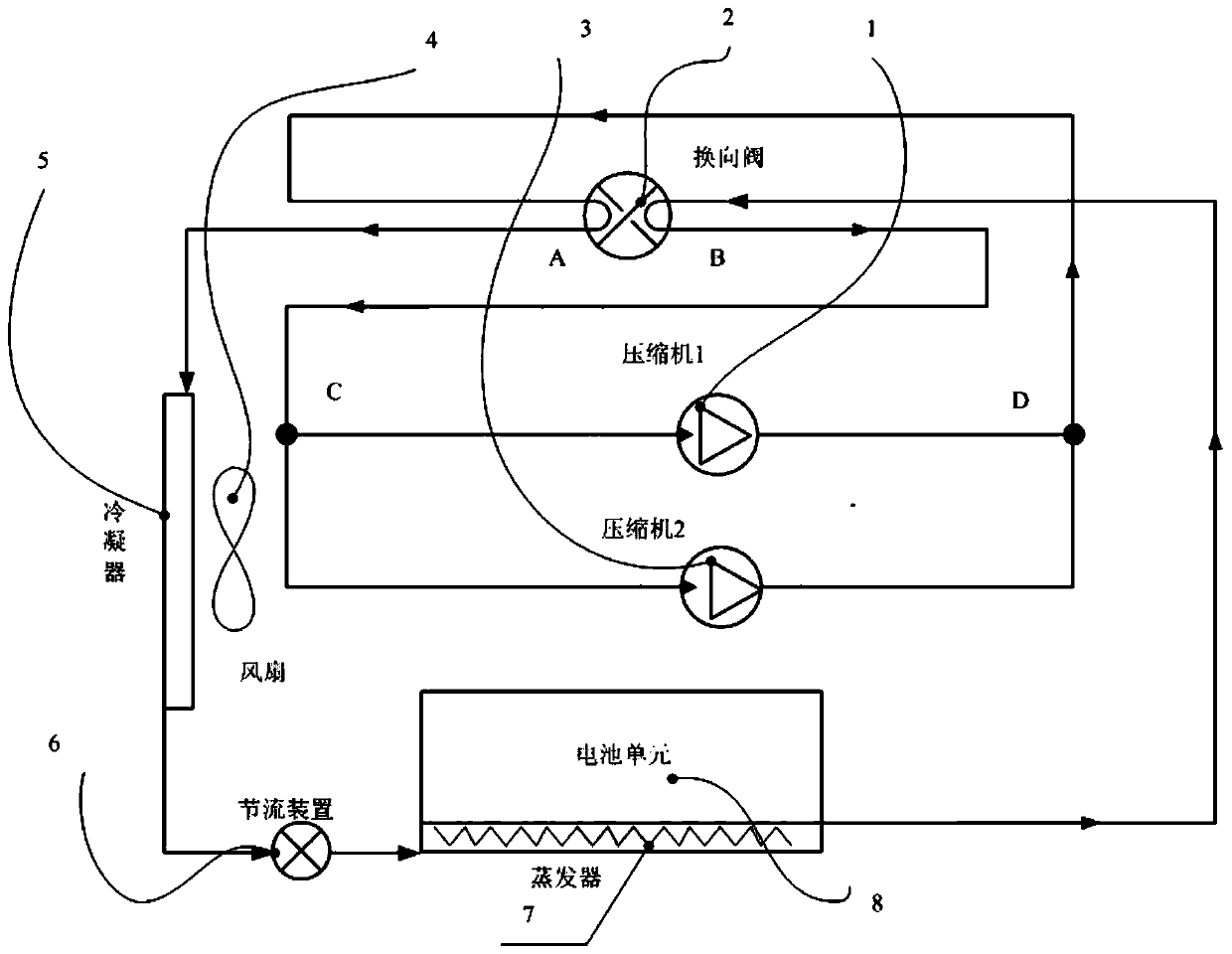

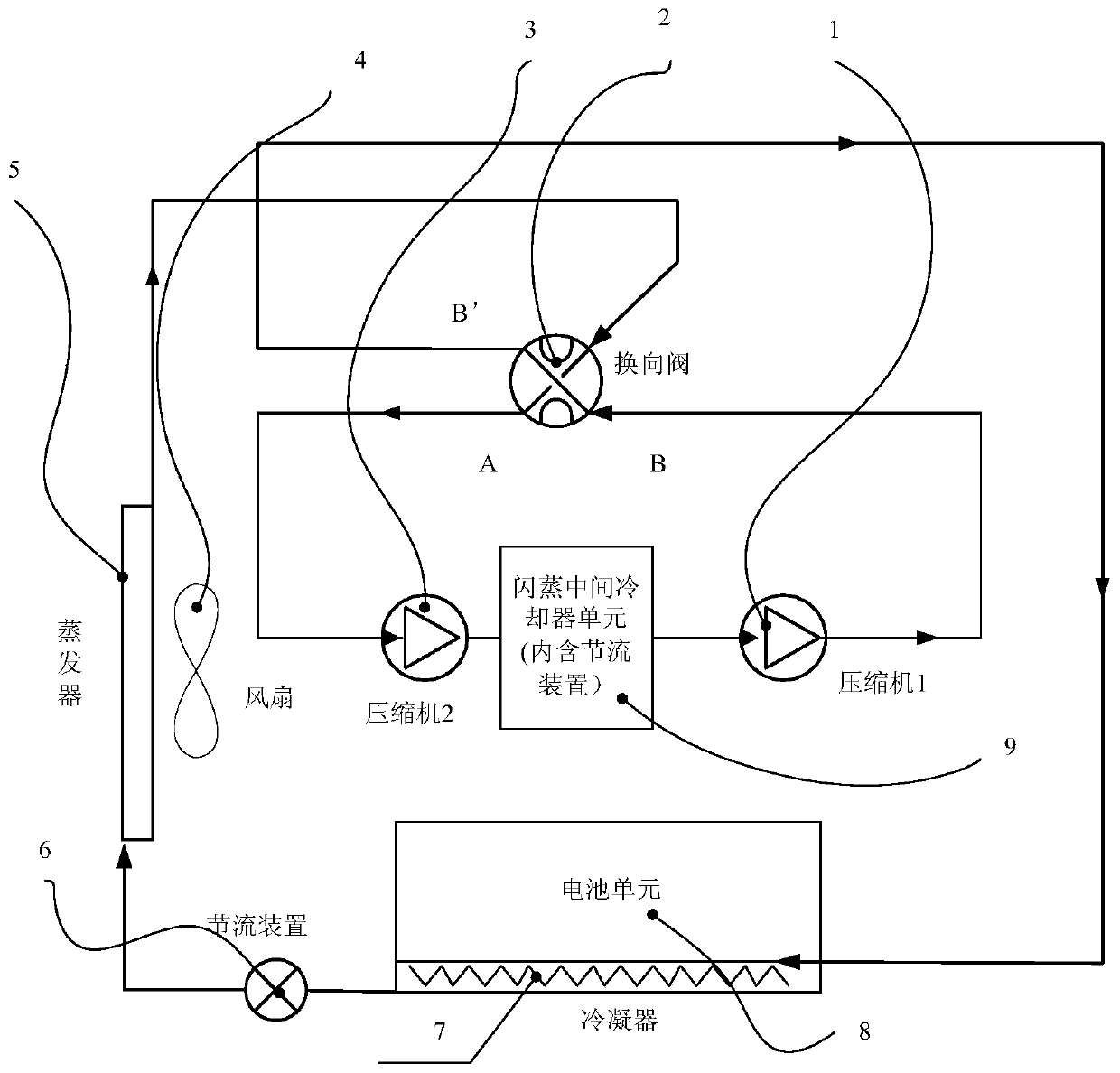

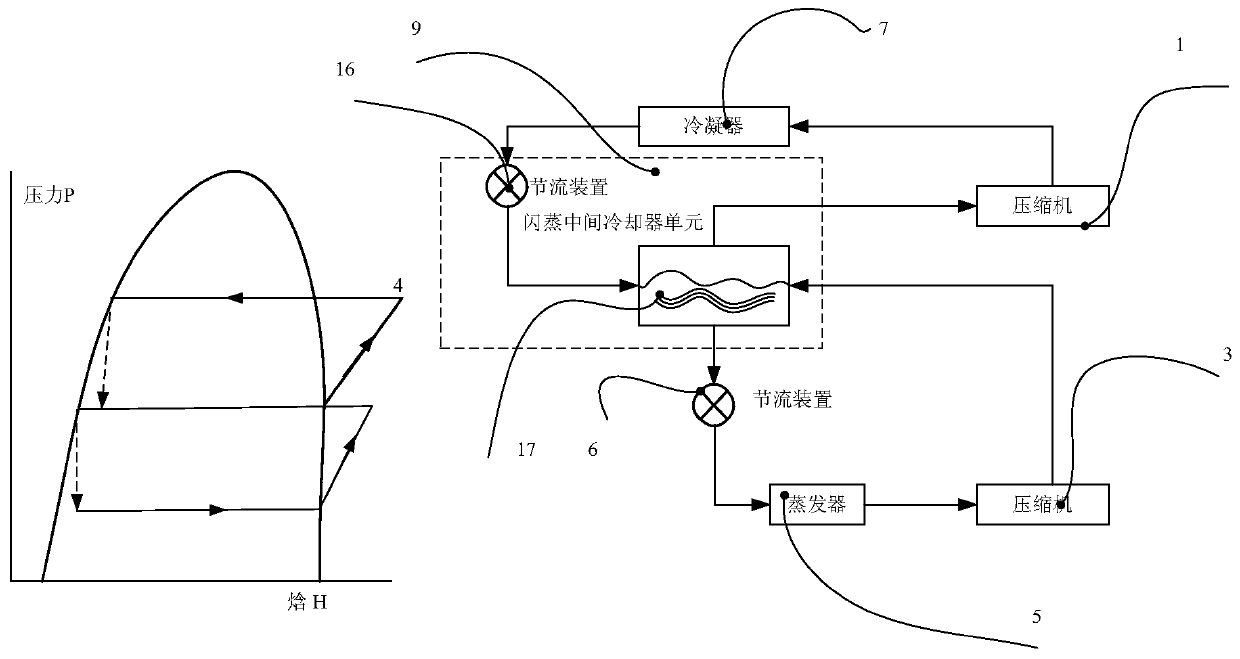

[0031] see figure 1, is the refrigeration working principle of the present invention, and the system includes a compressor unit (including the first compressor 1 and the second compressor 3), a four-way reversing valve 2, a condenser fan 4, and an external heat exchanger 5 (in In different states, they act as condensers or evaporators respectively), throttling device 6 (expansion valve or its type throttling mode), battery heat exchanger 7 (in different states, act as evaporators or condensers respectively function), the battery unit 8 (cooling object), and other related components such as the connecting pipelines of each section and the switching valves that control the on-off of each pipeline.

[0032] When the battery is in the cooled stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com