Circular-blow cooling device

A cooling device and ring blowing technology, applied in the field of spinning manufacturing, can solve problems such as unfavorable melt spinning production and reduce production efficiency, and achieve the effects of easy cleaning and maintenance, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

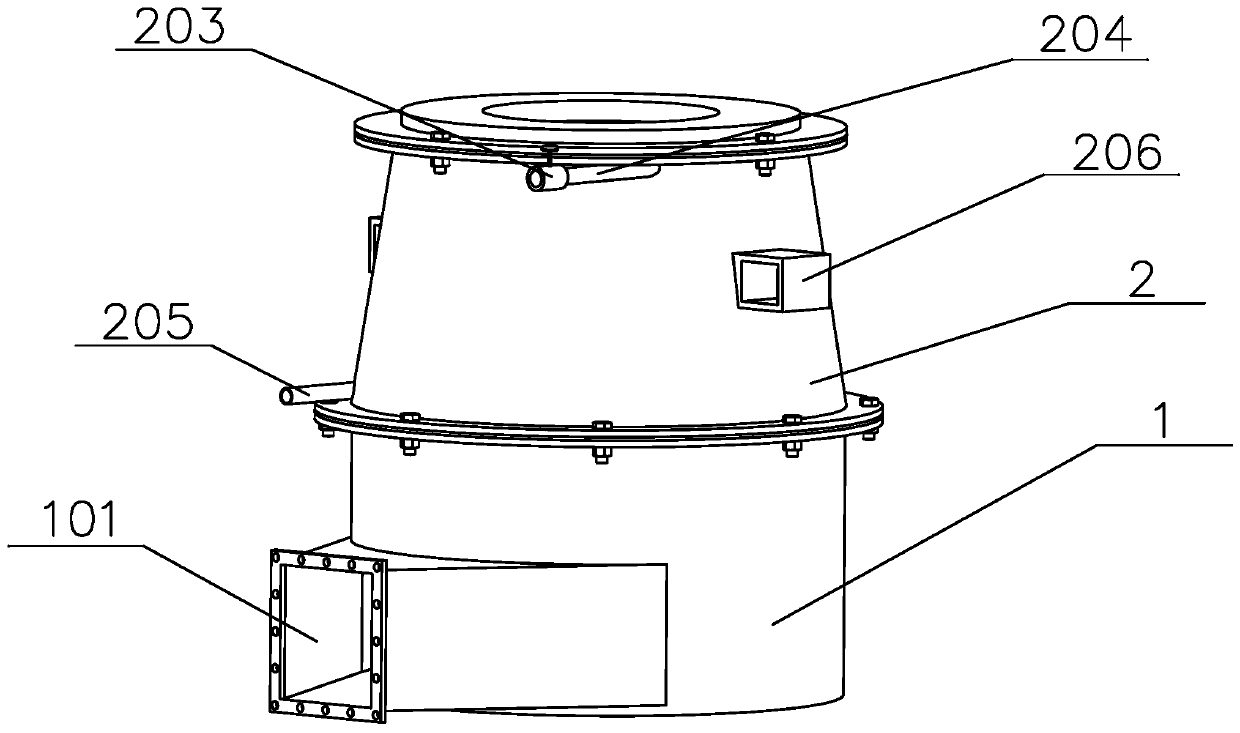

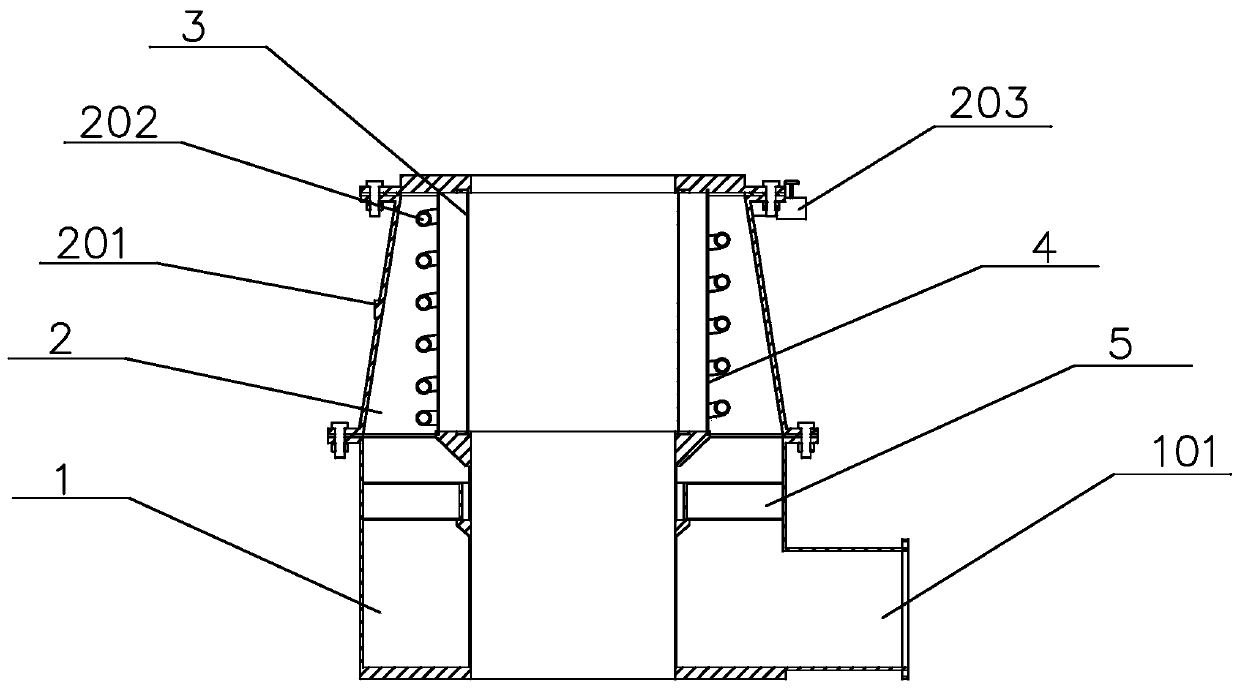

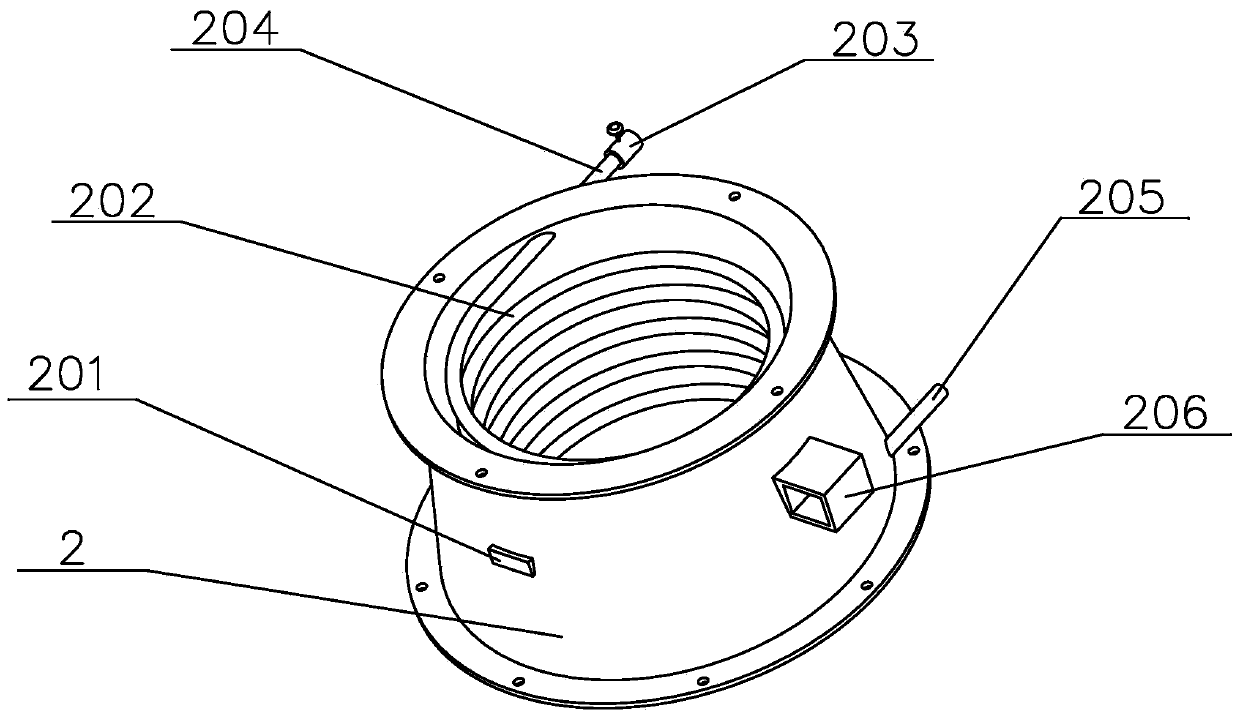

[0020] Such as Figure 1-Figure 3 As shown, the present embodiment provides a cooling device for surrounding air, including a lower air chamber 1, an upper air chamber 2, and an intermediate rectifying layer 5 between the lower air chamber 1 and the upper air chamber 2. The lower air chamber 1, the upper air chamber 2 Both the upper wind chamber 2 and the intermediate rectifying layer 5 are in a coaxial annular shape, the inner ring of the upper wind chamber 2 is a perforated plate 4, and the upper wind chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com