Film bulk acoustic resonator, filter and preparation method of film bulk acoustic resonator

A thin-film bulk acoustic wave and resonator technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems that thin-film bulk acoustic wave resonators cannot be used normally, and the mechanical strength is not enough, so as to avoid incomplete corrosion, enhance mechanical firmness, reduce The effect of device loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

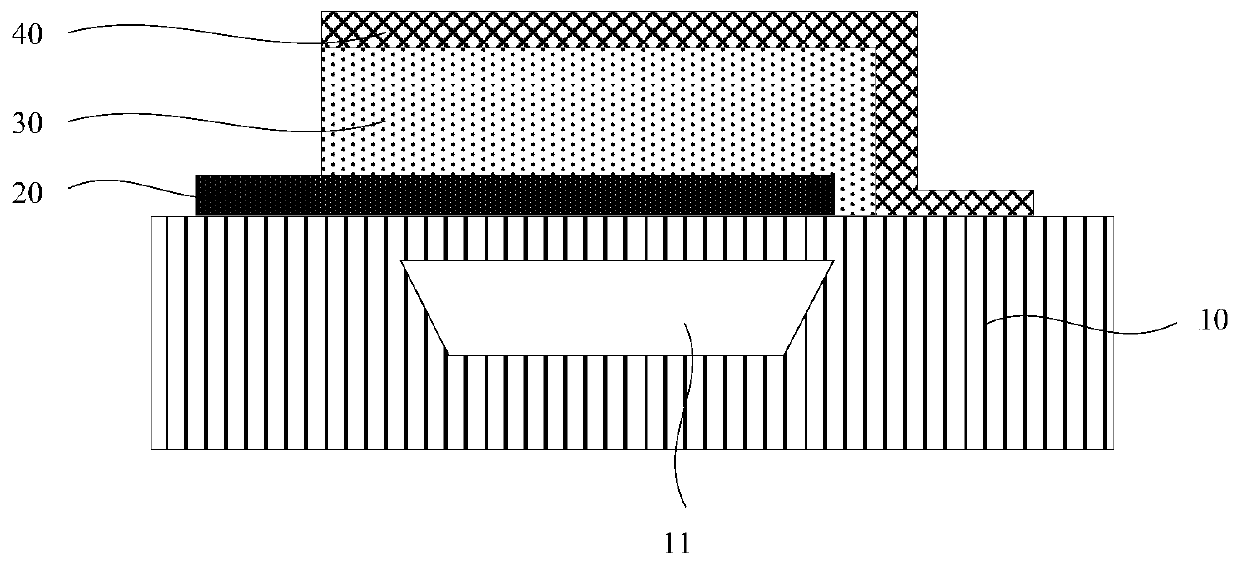

[0042] An embodiment of the present invention provides a film bulk acoustic resonator. figure 1 For a schematic cross-sectional structure diagram of a thin film bulk acoustic resonator provided in an embodiment of the present invention, see figure 1 , the thin film bulk acoustic resonator comprises: a support structure 10, an air gap 11 is arranged inside the support structure 10; a lower electrode 20, a piezoelectric layer 30 and an upper electrode 40 formed on the support structure 10 are arranged in sequence from bottom to top.

[0043] Optionally, the piezoelectric layer 30 wraps a part of the lower electrode 20, and the upper electrode 40 wraps a part of the piezoelectric layer 30 again.

[0044] In this embodiment, the thin film bulk acoustic resonator includes a support structure 10 with an air gap 11 inside, and a piezoelectric oscillating acoustic stack composed of a lower electrode 20 , a piezoelectric layer 30 and an upper electrode 40 . The film bulk acoustic wave...

Embodiment 2

[0053] On the basis of the above embodiments, an embodiment of the present invention provides a filter, including the thin film bulk acoustic resonator described in any of the above embodiments.

[0054] The filter in this embodiment includes the thin film bulk acoustic resonator described in any of the above embodiments, and the support structure included in the thin film bulk acoustic resonator is provided with an air gap inside, forming a bottom-up arrangement on the support structure. Piezoelectric oscillating acoustic stack composed of electrodes, piezoelectric layer and upper electrode, supporting structure supporting the piezoelectric oscillating acoustic stack composed of lower electrode, piezoelectric layer and upper electrode, and the whole film bulk acoustic resonator forms an air interface on the lower surface of the lower electrode , in order to achieve the purpose of reflecting sound waves, reducing device loss, and improving the quality factor of the resonance un...

Embodiment 3

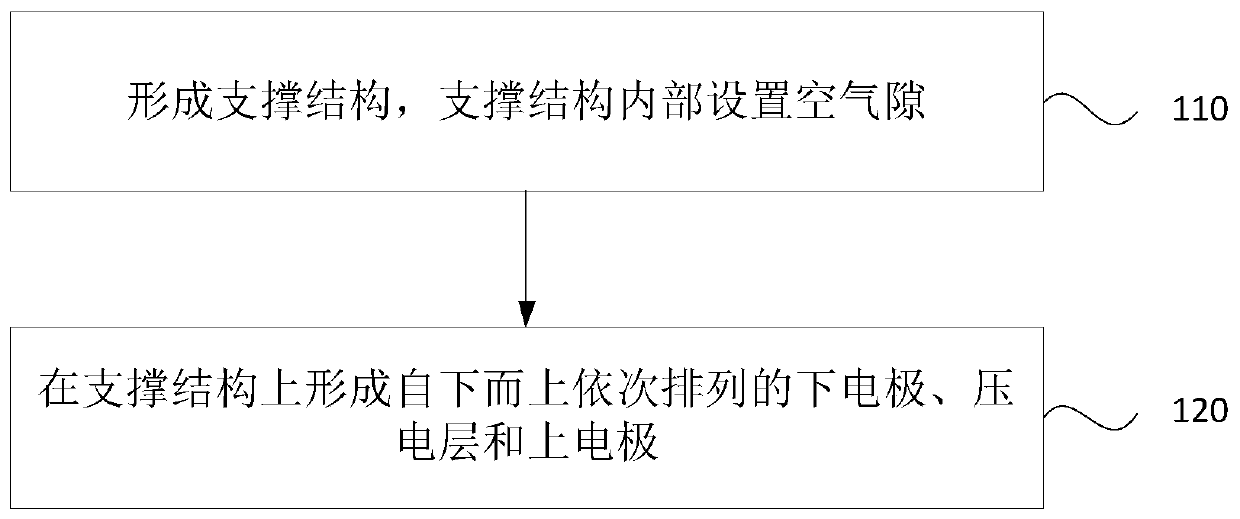

[0056] On the basis of the above embodiments, the embodiments of the present invention provide a method for manufacturing a thin film bulk acoustic resonator, image 3 A flow chart of a method for preparing a thin film bulk acoustic resonator provided by an embodiment of the present invention is shown, see image 3 , the method includes the following steps:

[0057] Step 110, forming a support structure, and setting an air gap inside the support structure.

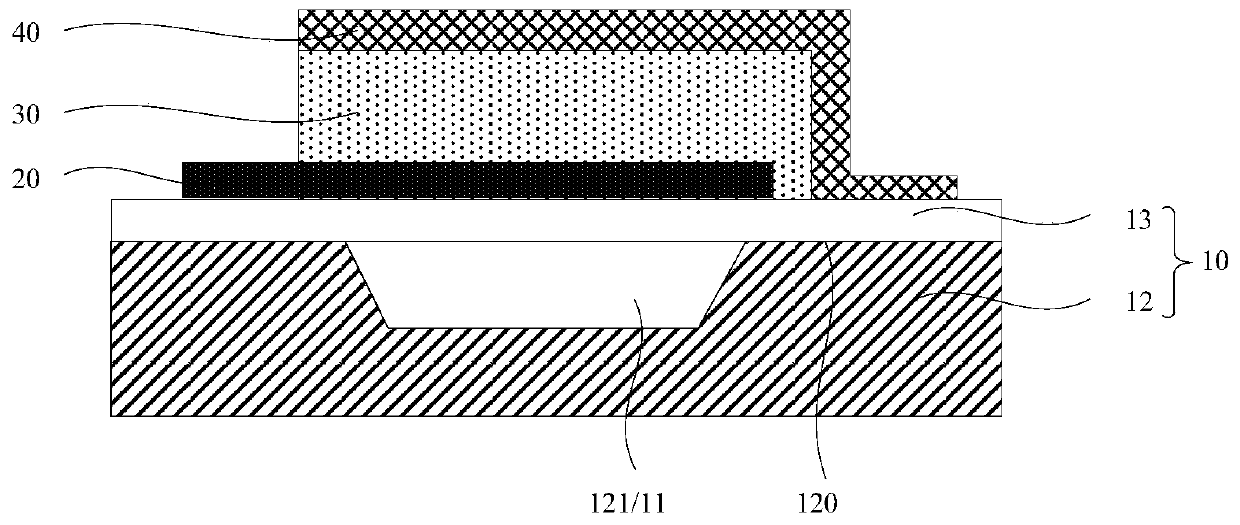

[0058] see Figure 4 , forming a support structure 10 , and an air gap 11 is provided inside the support structure 10 .

[0059] Step 120 , forming a lower electrode, a piezoelectric layer and an upper electrode sequentially arranged from bottom to top on the supporting structure.

[0060] see Figure 5 , on the supporting structure 10, a lower electrode 20, a piezoelectric layer 30, and an upper electrode 40 are sequentially arranged from bottom to top.

[0061] In this embodiment, the thin film bulk acoustic resonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com