Runway type micro-ring optical switch based on silicon dioxide/polymer mixed waveguide and preparation method of runway type micro-ring optical switch

A silicon dioxide and polymer technology, applied in optical waveguide, optical waveguide coupling, optics, etc., can solve the problems of large device size, difficulty in large-scale integration, and only tens of milliwatts, etc., to achieve compact end face size, The effect of low processing cost and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

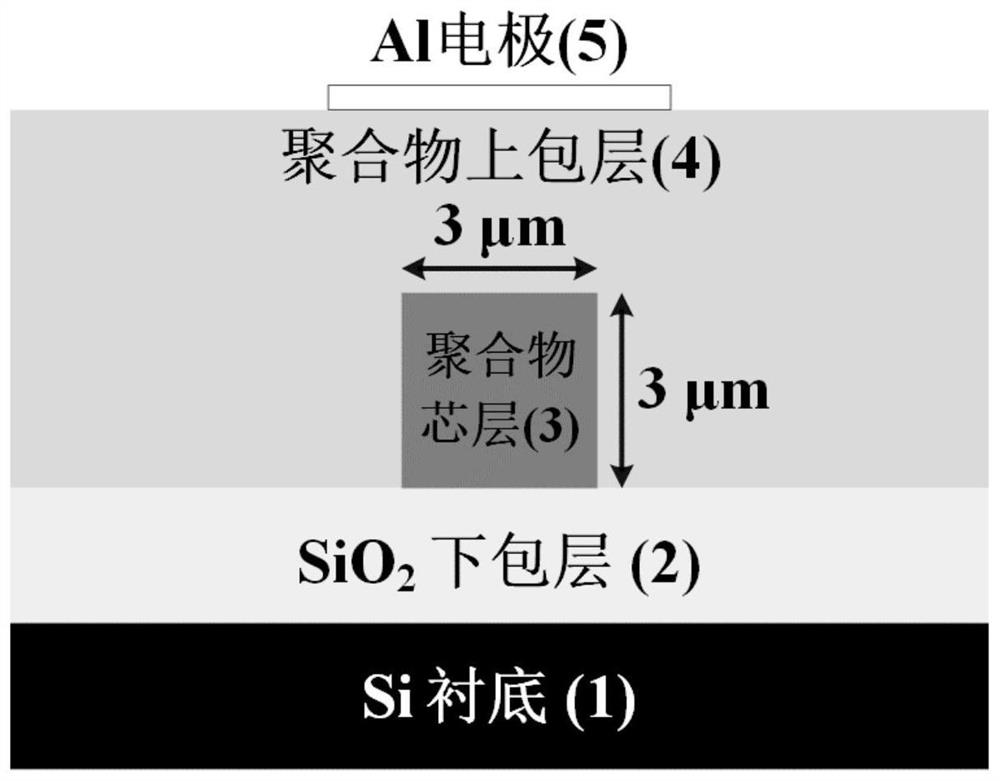

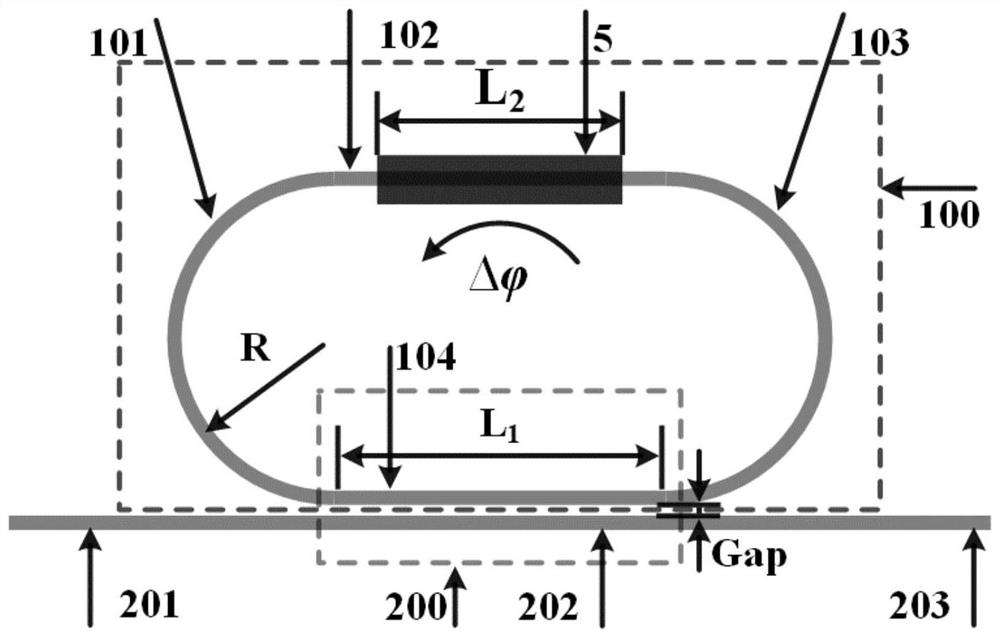

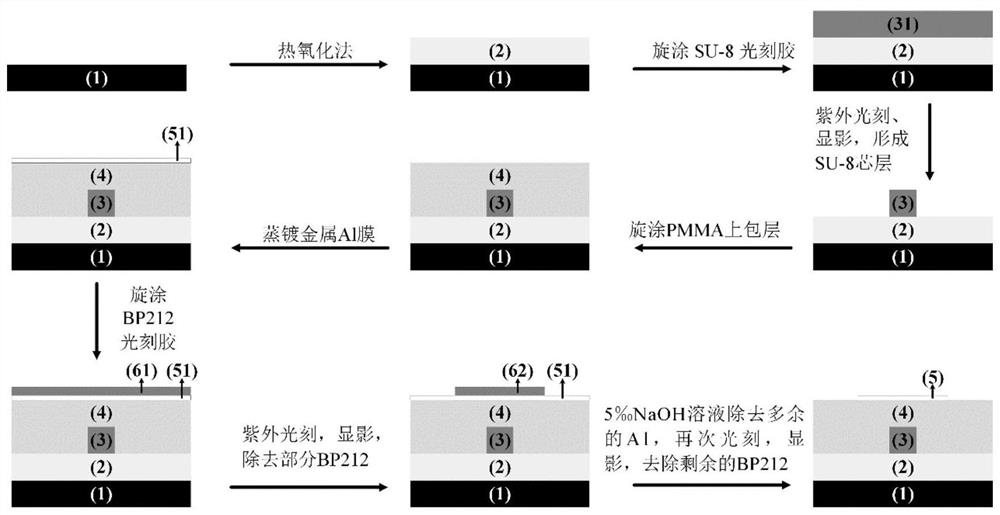

[0034] as attached figure 1 Shown is a schematic cross-sectional view of the polymer / silica hybrid waveguide, from bottom to top, consisting of Si substrate (1), SiO2 It consists of a lower cladding layer (2), a polymer core layer (3), a polymer upper cladding layer (4) and a metal electrode (5). The SiO 2 The lower cladding layer (2) can be grown by thermal oxidation or (Plasma Enhanced Chemical Vapor Deposition, PECVD) deposition method. In this embodiment, thermal oxidation is used to grow SiO 2 , the refractive index is 1.4456. The polymer core layer (3) can use a polymer material with a negative thermo-optic coefficient, including SU-8 2002, SU-8 2005, EpoCore, etc. In this embodiment, the SU-8 2002 material is used as the polymer material The material of the core layer (3) has a refractive index of 1.573. The polymer upper cladding (4) material can be polymethyl methacrylate (PMMA), polyethylene (PE), polyester (PET), polystyrene (PS), EpoClad, etc., in this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com