Glass separation and recovery device for broken glass photovoltaic module and recovery method

A technology for separation and recycling, photovoltaic modules, applied in grain processing and other directions, to achieve the effect of reducing recycling costs, improving purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

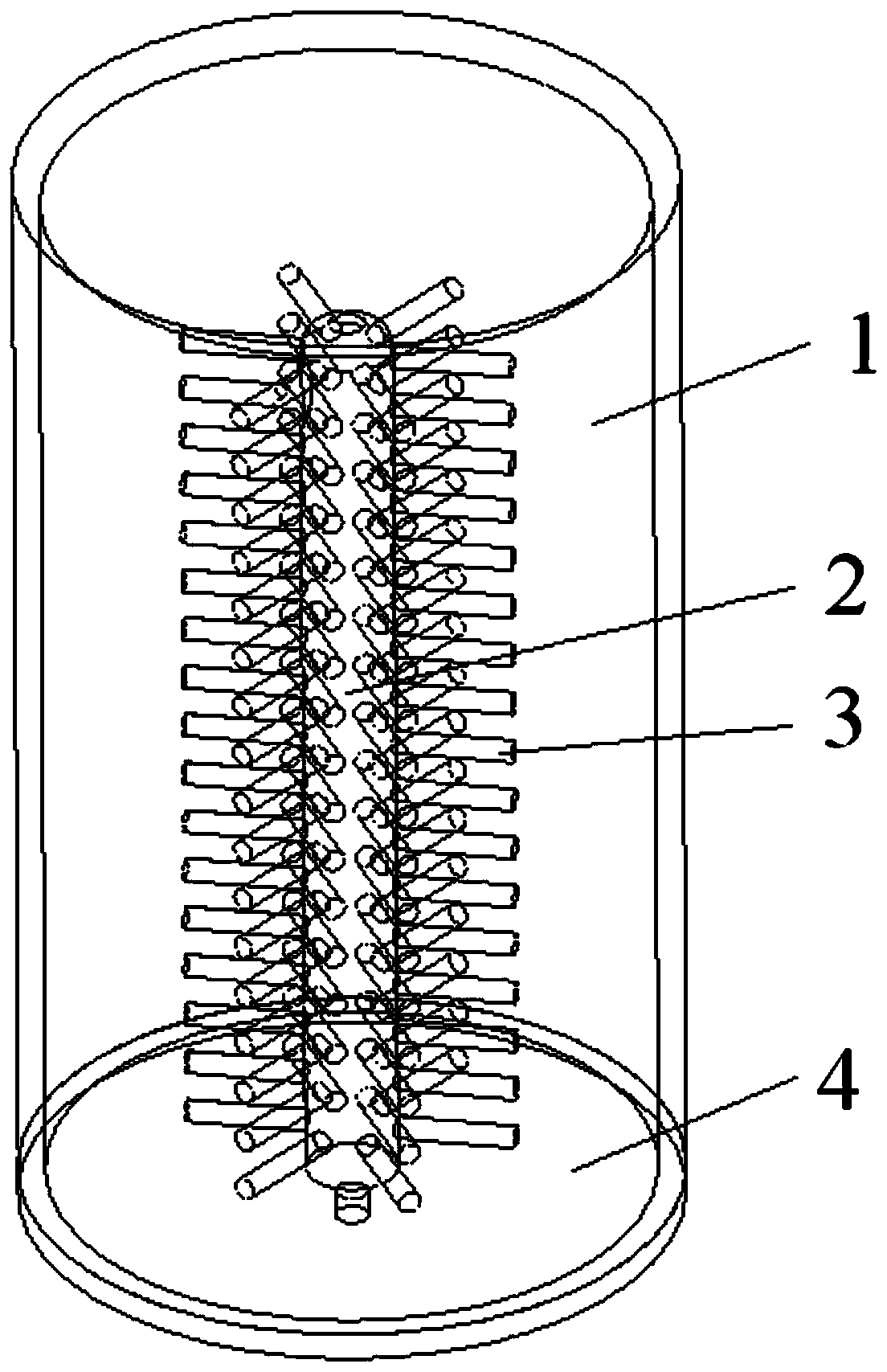

[0022] A glass separation and recovery equipment for cullet photovoltaic modules, such as figure 1 As shown, it includes a casing 1, which is sealed and connected with the base 4 below to form a sealed cavity; a rotatable central stick 2 is arranged in the sealed cavity, and the lower end of the central stick 2 is fixedly connected with the base 4, and the central stick A plurality of percussion rods 3 are evenly distributed on the 2.

[0023] Wherein, the center stick 2 is vertically arranged at the center of the base 4 . A plurality of knocking sticks 3 are vertically arranged on the center stick 2 . A plurality of knocking sticks 3 are arranged neatly on the center stick 2 in rows and columns. The material of the casing 1 is transparent acrylic material.

[0024] The present invention adopts the physical method to reclaim t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com