Perforating structure used for laptop mold

A notebook computer and hole-opening structure technology, which is applied to machine tools, manufacturing tools, boring/drilling and other directions suitable for grinding the edge of workpieces, can solve the problems of complex processing procedures and low processing efficiency, and avoid flying around, Improve the effect of grinding and increase the surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

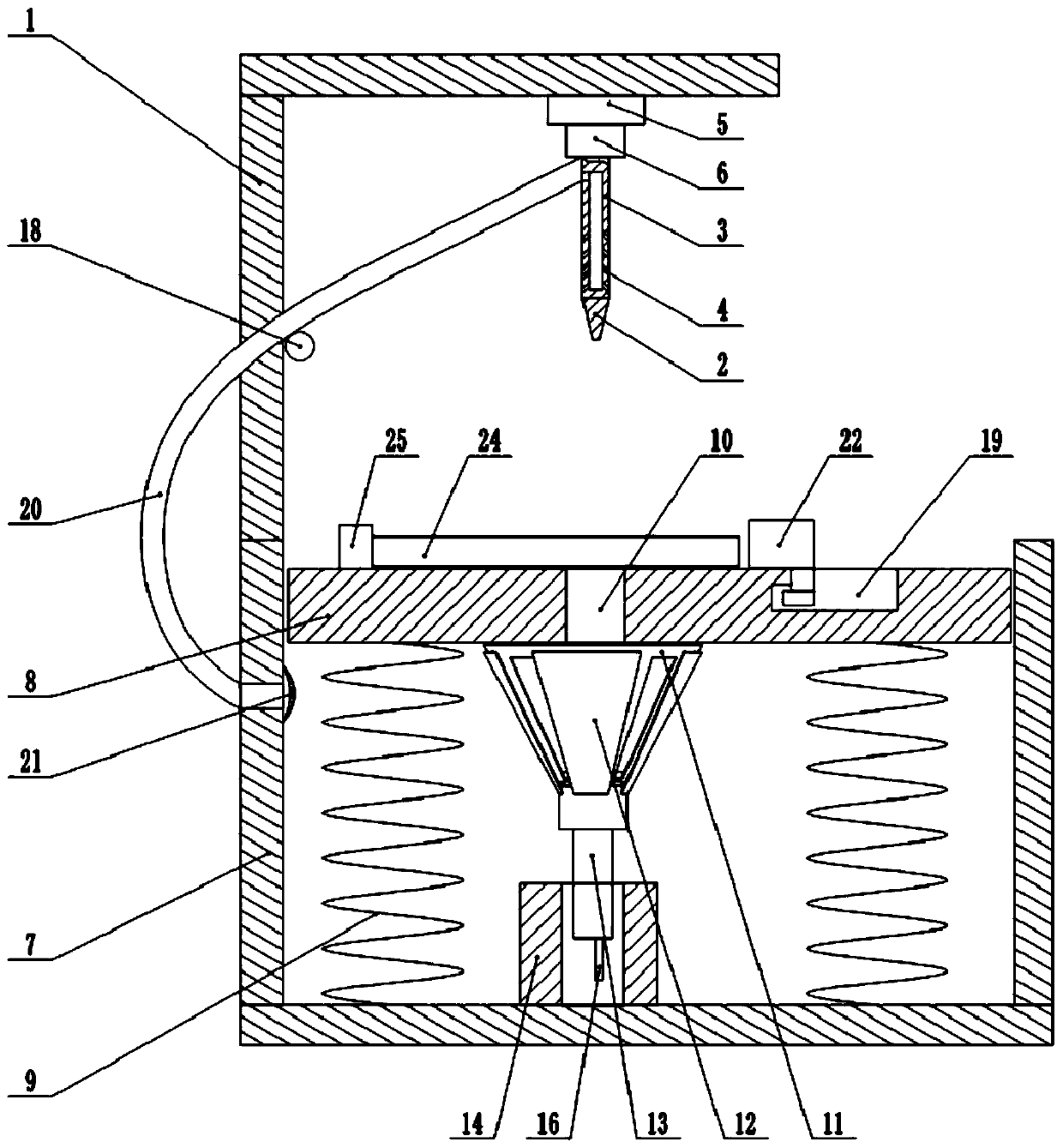

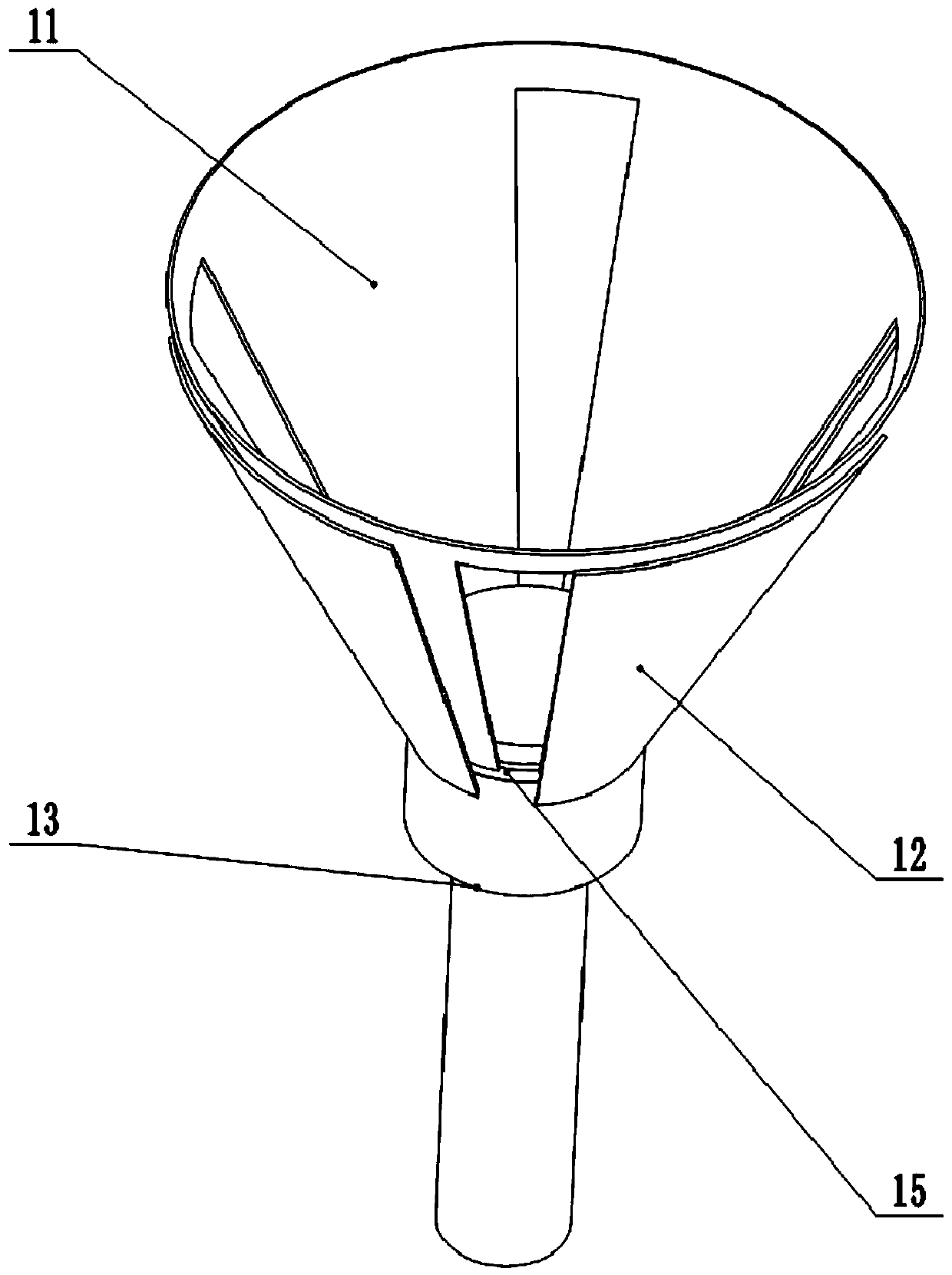

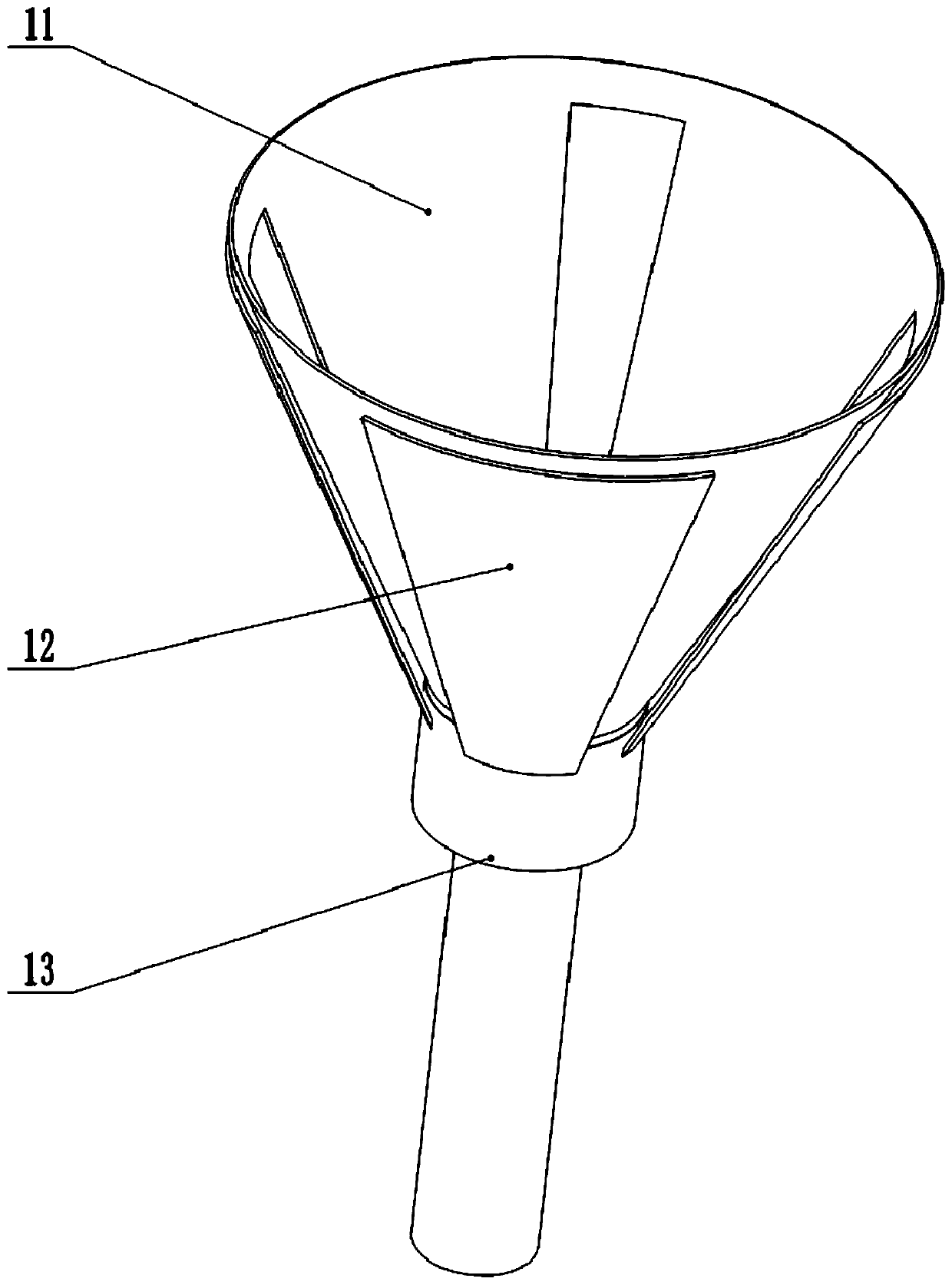

[0034] as attached figure 1 Shown: the opening structure used for notebook computer molds, including the frame 1 and the drill bit 2, the upper end of the drill bit 2 is fixedly clamped with a grinding rod 3, and a grinding hole 4 is opened on the peripheral wall of the grinding rod 3, and the grinding hole 4 is inclined toward Bottom setting; the upper end of the frame 1 is fixed with a cylinder 5 through bolts, and the telescopic rod 6 is slidably connected in the cylinder 5, and the lower end of the telescopic rod 6 is connected with a motor through bolts, and the output shaft of the motor is fixedly clamped with the upper end of the grinding rod 3 .

[0035] The lower side of the frame 1 is fixed with a collection box 7 by bolts, and the collection box 7 is vertically slidably connected with a load plate 8 through a guide rail. Welding, elastic part 9 is stage clip here; The outer peripheral cover of elastic part 9 is provided with the telescopic tube that is used to prev...

Embodiment 2

[0043] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the clamps include a first clamp and a second clamp 22. Here, for convenience of description, the one located on the upper side of the mold 24 is named the first clamp, and the one on the right side of the mold 24 is named the second clamp. Clamp 22, the first clamp and the second clamp 22 are respectively slidably connected with the carrier plate 8, and the sliding directions of the first clamp and the second clamp 22 are perpendicular to each other, the structure of the second clamp 22 of the first clamp is the same, here the first The structure of the clamp is described as an example. The first clamp is rotatably connected with a roller 23 through a bearing. When using this solution, the mold 24 is placed on the carrier plate 8, and the left side and the lower side of the mold 24 are against the side wall of the collection box 7, then the first clamp is slid downward, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com