A bottled drinking water plastic barrel blow molding device

A blow molding device and drinking water technology, which is applied in the field of blow molding, can solve the problems of affecting the overall quality of the bucket, uneven force on the side wall of the molding raw material, and uneven thickness of the side wall of the bucket.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

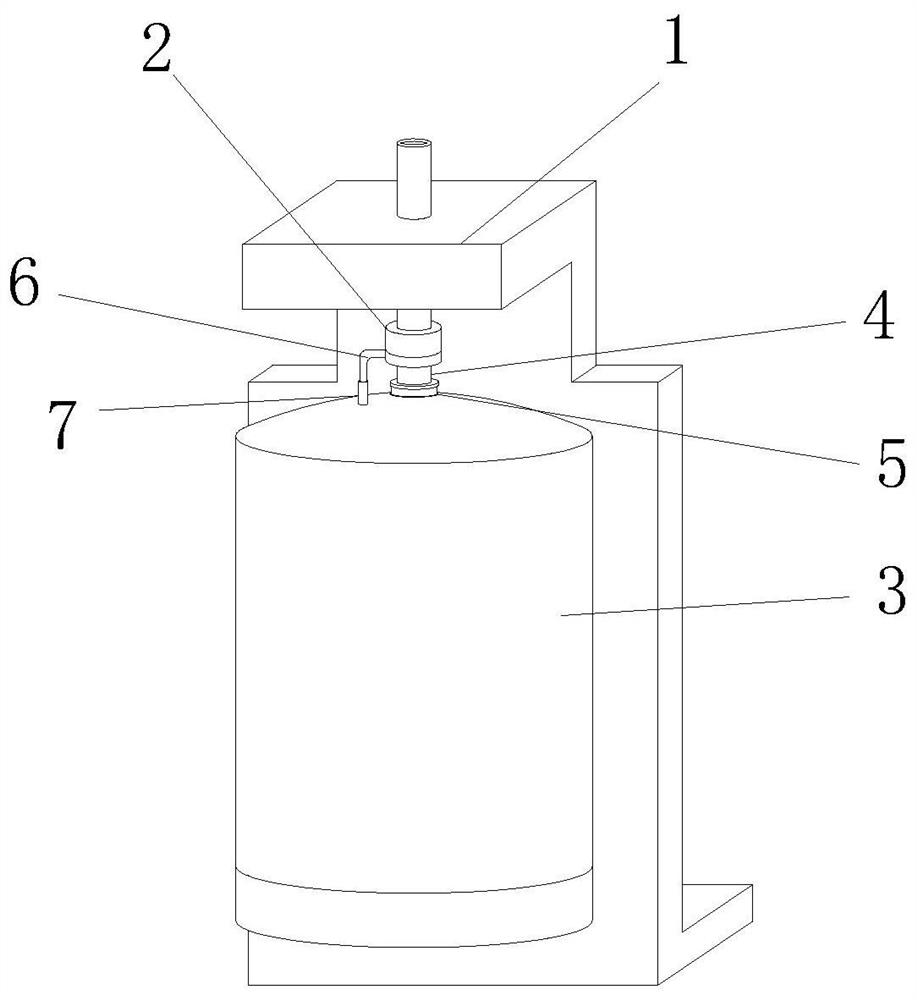

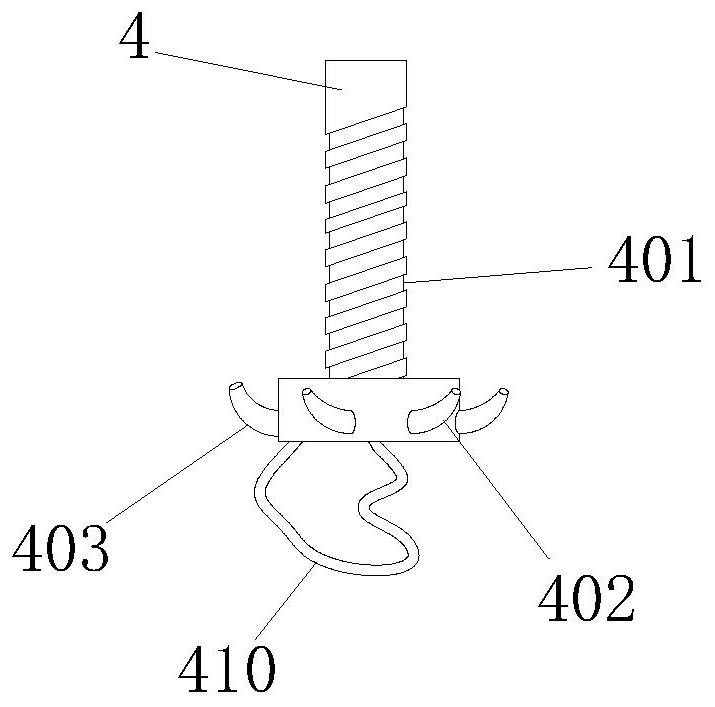

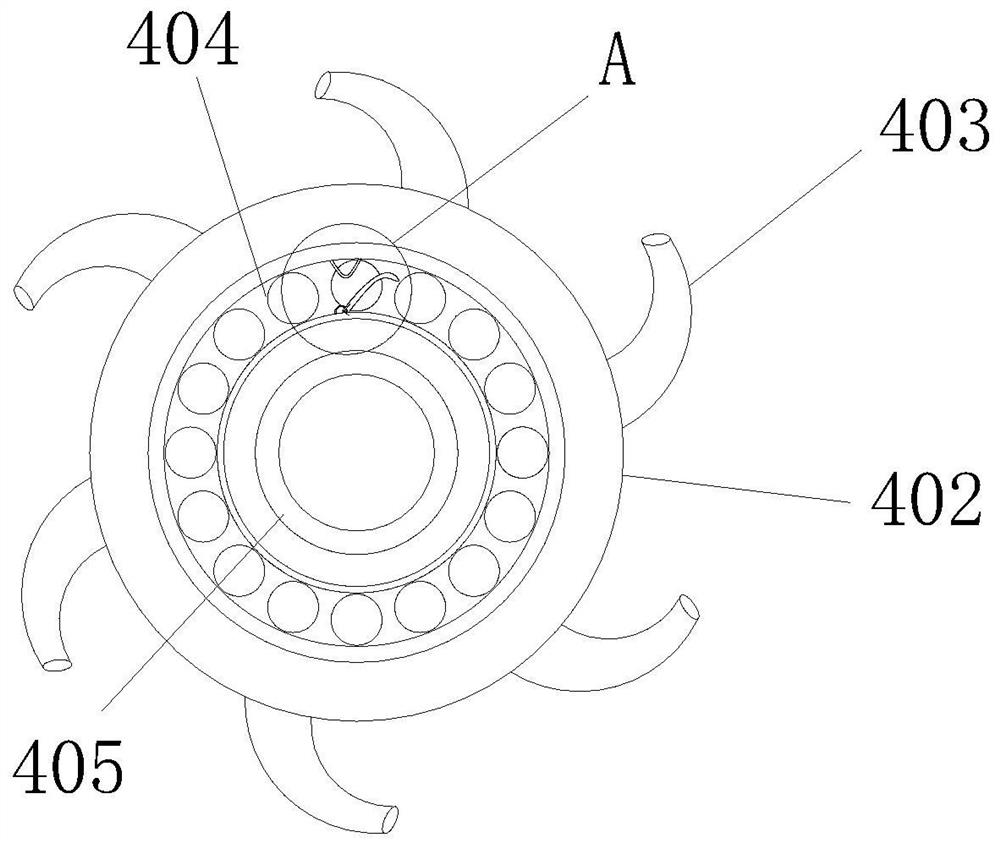

[0032] Embodiment: a kind of bottled drinking water plastic barrel blow molding device, such as Figure 1-6 As shown, it includes a fixed frame 1, and the fixed frame 1 is a Z-shaped support. The front of the fixed frame 1 is equipped with a blow mold 3 through a telescopic device. The telescopic device is an existing known technology, so it will not be repeated here. 3 is a cylindrical hollow barrel, the top of the blow mold 3 is provided with a circular top opening 301, the center of the top plate of the fixing frame 1 is fixed vertically downward with a fixing rod, and the lower end of the fixing rod is fixed with a fixing sleeve 2, and the fixing sleeve 2 is a circular sleeve, and the lower end of the fixed sleeve 2 is snapped vertically downward to connect with the air intake pipe 4, which is a circular hollow long pipe, and the air intake pipe 4 is plugged into the inside of the blow mold 3 through the top port 301, The inside of the top port 301 is plugged with a loam c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com