Using method of aromatic hydrocarbon enriched wax oil in heavy oil up-flowing type hydrogenation thermal cracking reaction process

A technology of cracking reaction and hydrogenation reaction, which is applied in the direction of only multi-stage series refining and cracking process, treatment of hydrocarbon oil, petroleum industry, etc., and can solve the problems of lower overall economy, long hydrogenation process, and no reports. , to achieve the effect of saving system scale, reducing hydrogen consumption and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

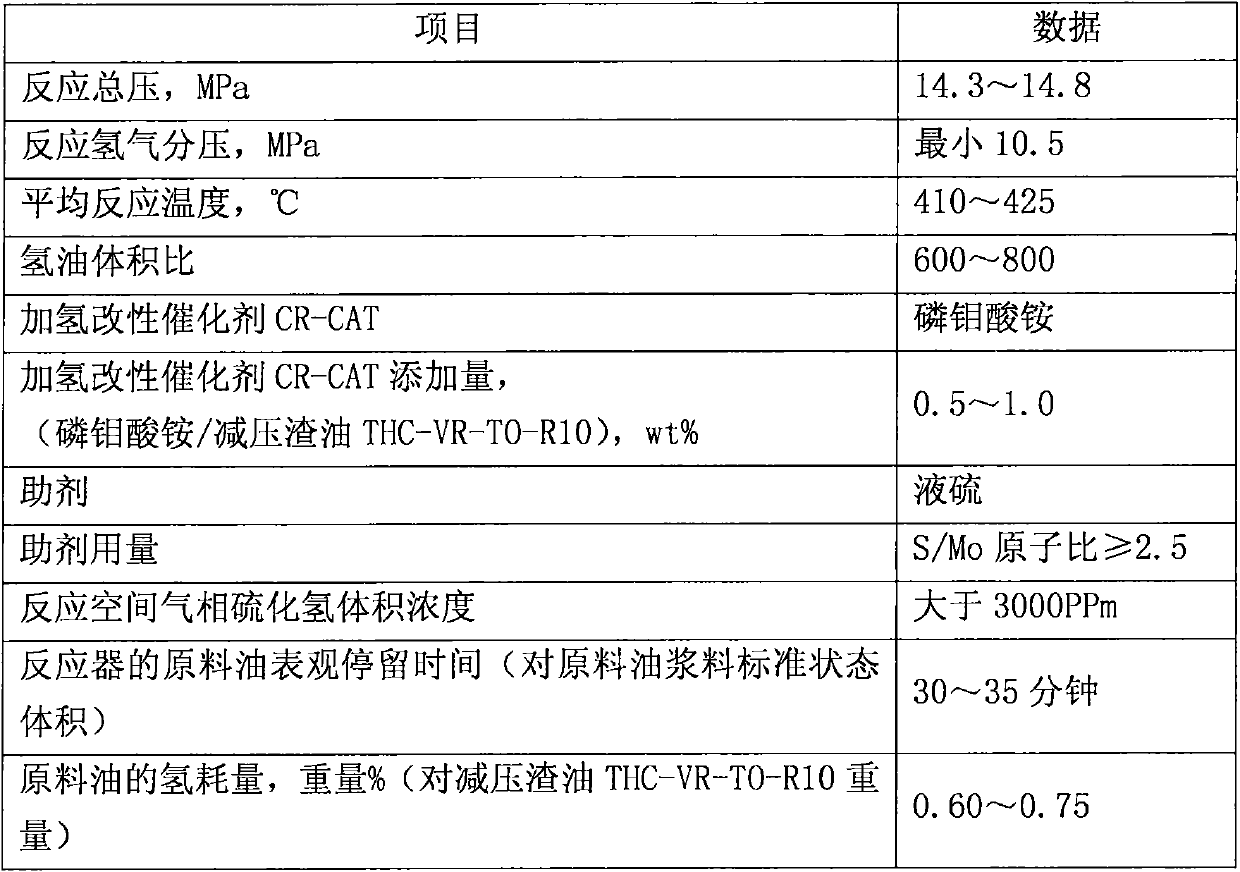

[0760] Based on the comparative example, in order to improve the overall conversion rate of the hydrothermal cracking raw material oil vacuum residue, the usage of the aromatic-rich wax oil of the present invention in the upflow hydrothermal cracking reaction process of heavy oil is adopted, and the steps are as follows:

[0761] Add the wax oil catalytic cracking heavy cycle oil (catalytic cracking wax oil) as aromatic-rich wax oil (aromatic-rich medium wax oil) to the second reactor of the suspended bed hydrothermal cracking reaction R10 of vacuum residue R10F Instead of passing through the first reactor R10A, the ratio of the weight of aromatic-rich medium wax oil to the weight of vacuum residue R10F is 20%;

[0762] Under the condition that the yield of benzene insolubles in the hydrothermal cracking reaction of vacuum residue R10F does not increase (not more than 2.2% to the quality of raw material oil), the single-pass conversion rate of vacuum residue R10F can be increas...

Embodiment 2

[0764] Based on Example 1, in order to increase the overall hydrothermal cracking conversion rate of the vacuum residue R10F, the present invention is used to perform cyclic hydrothermal cracking on the hydrothermal cracking products heavy wax oil and residue.

[0765] In the fractionation step of hydrothermal cracking products, vacuum fractionation deep draws hydrothermally cracked medium wax oil THC-KVGO, and the suspended bed hydrothermal cracking product residual oil (>475°C) is separated into three fractions:

[0766] The first fraction is the heavy oil hydrothermal cracking reaction process R10 product medium wax oil THC-MVGO (mainly composed of hydrocarbons with a conventional boiling point of 400-520 °C;

[0767] The second fraction is the hydrothermal cracking product heavy wax oil THC-HVGO, which is mainly composed of hydrocarbons with a conventional boiling point of 510-550 ° C, which is the R10 product vacuum distillation column feed washing section of the heavy oil...

Embodiment 3

[0778] Based on Example 2, the recycling method of light hydrogen-donating solvent is adopted to ease the operating conditions of the front reaction section R10A of the vacuum residue hydrothermal cracking reaction process R10 (mainly to reduce the operating temperature), and further improve the hydrothermal cracking Improve the overall thermal cracking conversion rate of raw oil vacuum residue R10F and reduce the amount of external residue.

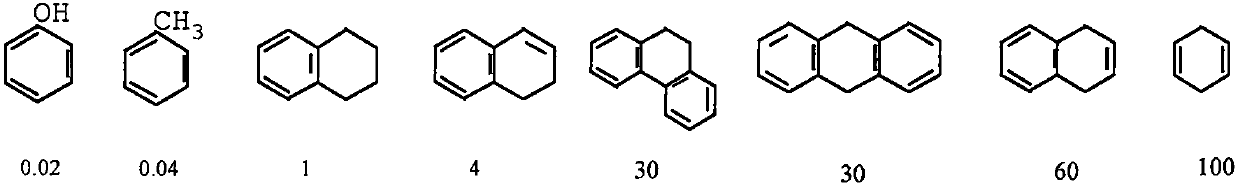

[0779]In order to alleviate the operating conditions of the front reaction section R10A of the vacuum residue hydrothermal cracking reaction process R10 (mainly to reduce the operating temperature), and to further improve the overall thermal cracking conversion rate of the vacuum residue R10F of the hydrothermal cracking raw material oil , under the premise of fully improving the hydrogen supply efficiency and hydrogen transfer efficiency of the externally supplied light hydrogen supply solvent DS in the reactor of the front hydrogenation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com